How to optimize the production process with the arrival of 3D?

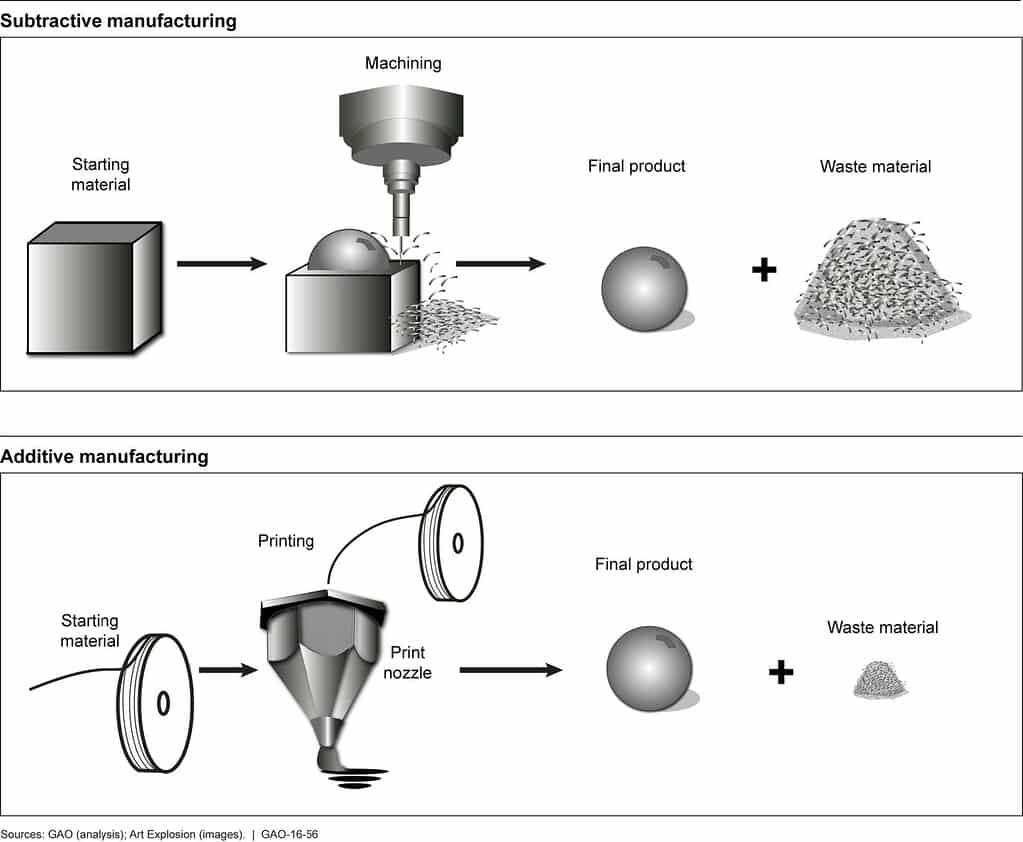

Additive manufacturing processes build objects by adding material layer by layer, while subtractive manufacturing removes material from a solid form to create parts. Although these approaches are fundamentally different, subtractive and additive manufacturing processes are often used side by side due to overlap in their respective fields of application and contributions.

At first, it can be difficult to understand how to make the best use of each type of technology to optimize product development and production. In both cases, it makes sense to use one approach rather than another, for example, a process may be more useful for a certain volume of production or at a specific stage of product development.

Subtractive production

Subtractive manufacturing is a generic term for various controlled machining and material removal processes that begin with solid blocks, bars, plastic bars, metal or other materials that are shaped by material removal by cutting, drilling and grinding.

These processes are performed manually or, more commonly, with the help of a computer numerical control (CNC).

The CNC

In the CNC, a virtual model designed in the CAD software is used as input for the production tool. The software simulation is combined with the user input to generate paths that guide the cutting tool through the geometry of the workpiece. These instructions explain to the machine how to perform the necessary cuts, channels, holes and all other features that require material removal, taking into account the speed of the cutting tool and the material feed. CNC tools produce parts from these computer-aided production (CAM) data, with little or no human assistance or interaction.

In addition, subtractive manufacturing processes are generally used to create plastic or metal parts for prototyping, tool making and end use. They are ideal for applications that require tight tolerances and geometries that are difficult to model, cast, or produce with other traditional manufacturing methods.

Of course, subtractive manufacturing offers a variety of materials and machining methods. In fact, softer materials are much easier to machine into the desired shape, but consume more quickly.

Additive production

Unlike the process of removing material from a larger part, additive manufacturing or 3D printing processes construct objects by adding material one layer at a time, each subsequent layer being bound to the previous layer until the part is complete.

Like subtractive CNC tools, additive manufacturing technologies create parts from CAD models. The preparation of models for 3D printing using the print preparation software or slicing software (slice cutting) is generally automated, which makes job setup much easier and faster than CNC tools. Depending on the technology, the 3D printer deposits material, selectively melts and melts powder or cures photopolymeric liquid materials to create parts from CAM data. 3D molded parts often require some form of cleaning and finishing to achieve their final properties and appearance before they are ready for use.

Additive manufacturing is ideal for a wide range of engineering and manufacturing applications, including prototyping, tool making and casting pattern making. In addition, custom manufacturing of final parts can also be done with this technique and small series can be considered when the machining range is complex, or when the cost of making a mold is high or to reduce time-to-market. 3D printers offer a very high degree of design freedom and can produce complex designs that would be impossible or excessively expensive to create with any other production method.

The most common materials used in additive manufacturing are plastics and metals.

When to use subtractive and additive production?

Although there are fundamental differences, subtractive and additive production are not mutually exclusive. In fact, they are often used side by side and at different stages of product development and production.

For example, the prototyping process is often based on additive and subtractive tools. Early models and prototypes are generally cheaper and faster to produce with additive plastic manufacturing processes, such as stereolithography (SLA) or selective laser sintering (SLS). Undoubtedly, 3D printing offers a wide range of materials for functional prototyping of plastic parts. Additive technologies are generally more suitable for small parts and very complex or very complex projects.

When the subsequent stages of the development process require larger batches, the subtractive processes become more competitive. Larger and less complex objects are also more suitable for subtractive production. Because of the myriad of surface finishing options and process speed, subtractive manufacturing is often the best choice for producing finished parts that require tight tolerances.

The two processes

In production, subtraction and additive processes often complement each other in the production of tools, jigs, equipment, brackets, brackets, moulds and models. Manufacturers often use 3D molded plastic parts for fast, custom, low volume or replacement parts and choose large volume subtraction processes or parts subject to more extreme mechanical stress.

The use of additive and subtractive manufacturing results in a hybrid process. This allows designers and product manufacturers to combine the versatility and speed of additive manufacturing with the strength of subtracted parts.

The two processes

In production, subtraction and additive processes often complement each other in the production of tools, jigs, equipment, brackets, brackets, moulds and models. Manufacturers often use 3D molded plastic parts for fast, custom, low volume or replacement parts and choose large volume subtraction processes or parts subject to more extreme mechanical stress.

The use of additive and subtractive manufacturing results in a hybrid process. This allows designers and product manufacturers to combine the versatility and speed of additive manufacturing with the strength of subtracted parts.

Additive or subtractive production systems

Additive and subtractive technologies are available in various forms, with a range of costs and capacities, from office machines to large industrial equipment. Here is a table to give you concrete examples.

Training

Desktop printers are practically ready to use and require minimal training in setting up printing, maintenance, machine operation and finishing. Additive manufacturing systems for industry require dedicated personnel and comprehensive training.

Small CNC machines require moderate training in software, job setup, maintenance, machine operation, and finishing. Larger industrial subtraction systems require dedicated personnel and comprehensive training.

Installation requirements

The desktop / tabletop machines are suitable for the office and for a laboratory workshop environment with moderate space. Industrial 3D printers often require a dedicated space or room with HVAC control.

Small CNC machines are suitable for workshops. Industrial plants require a larger and more dedicated space.

Auxiliary equipment

Tools and systems (some automatic) for cleaning, washing, post-treatment and finishing, depending on the process.

Various equipment. The most advanced systems automate processes such as tool change, chip removal and handling, and coolant management.

Equipment costs

Professional desktop printers cost from € 3,500 for plastic. Large-scale industrial machines for metals start at € 150,000.

Small CNC machines for workshops start at around 2,000 euros. The most advanced workshop tools go above and beyond, depending on the number of axes, features, part size and tools needed for specific materials.