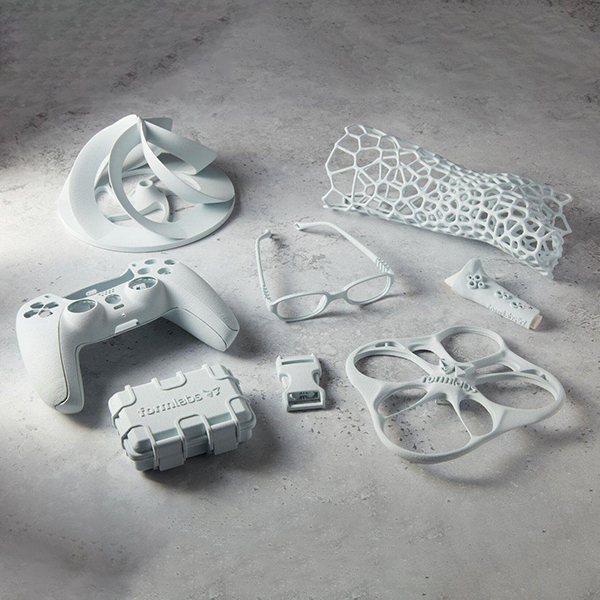

New from Formlabs: Nylon Tough and White for Fuse 1+. More freedom of material choice with Open Platform.

3DZ, an official Formlabs reseller, is pleased to introduce three new options that expand the capabilities of the Fuse 1+ 30W and other Formlabs printers, offering ideal solutions for prototyping and advanced manufacturing.

Nylon 12 White Powder – Precision and customization

The new Nylon 12 White Powder is an SLS 3D printing powder designed for making high-contrast parts, ideal for aesthetic and medical device applications. Because of its bright white color, this powder facilitates customization, allowing companies to dye finished parts to reflect corporate branding. The material’s versatility, combined with its precision, makes it an excellent choice for aesthetic prototypes and low-volume production, where biocompatibility and dimensional accuracy are critical. Nylon 12 White expands the range of powders available for Fuse 1+ 30W.

Nylon 12 Tough Powder – Strength and ductility for industrial applications

Nylon 12 Tough Powder is a new material for Fuse 1+ 30W designed for those seeking mechanical strength, dimensional accuracy, and impact resistance. Designed for industrial applications, this powder offers high ductility and precision, reducing deformation even in large parts. With a regeneration rate of up to 80 percent, it is a sustainable solution for functional prototyping and proof-of-concept of components requiring strength and flexibility, such as carabiners, hinges and ratchets, ski bindings, and crampons.

Open Platform – More freedom and flexibility in the choice of materials

Formlabs ecosystems become Open and offer three powerful tools that allow even complex problems to be solved autonomously by relying on the Form series SLA and Fuse series SLS printers.

1) Open Material Mode, an optional unlimited license that allows experienced users to print on Formlabs printers with third-party resins and powders. This new option allows users to experiment with materials that are not part of the Formlabs catalog, ideal for research and development teams or specialized applications. With Open Material Mode, users can maximize the potential of their printers, using all 405 nm photopolymer resins and all 1064 nm powders, for limitless customization.

2) PreForm print settings editor: you can now access the editor to customize print settings and performance, both for Formlabs patented materials and third-party materials certified by Formlabs. The print settings editor is ideal for those who want the freedom to make quick corrections for truly flawless project success. This feature allows you to make required changes and solve specific problems while still taking advantage of the proven reliability, convenience and accessibility of Form or Fuse series printers.

3) Formlabs-certified materials: the Formlabs engineering team has made a selection of the best third-party materials, certifying them and providing pre-adjusted print settings that are ideal for use on Formlabs’ SLA and SLS printers. Using a Formlabs-certified material with our ecosystem is suitable for those working in a specialized field, such as medical device manufacturing, where it is critical that materials meet specific regulations and approvals.

Formlabs' innovations expand the application possibilities of 3D printing, enabling companies to respond more flexibly to market needs. For more information, contact the 3DZ team, always available to support you in choosing the best solution.

Contact Us