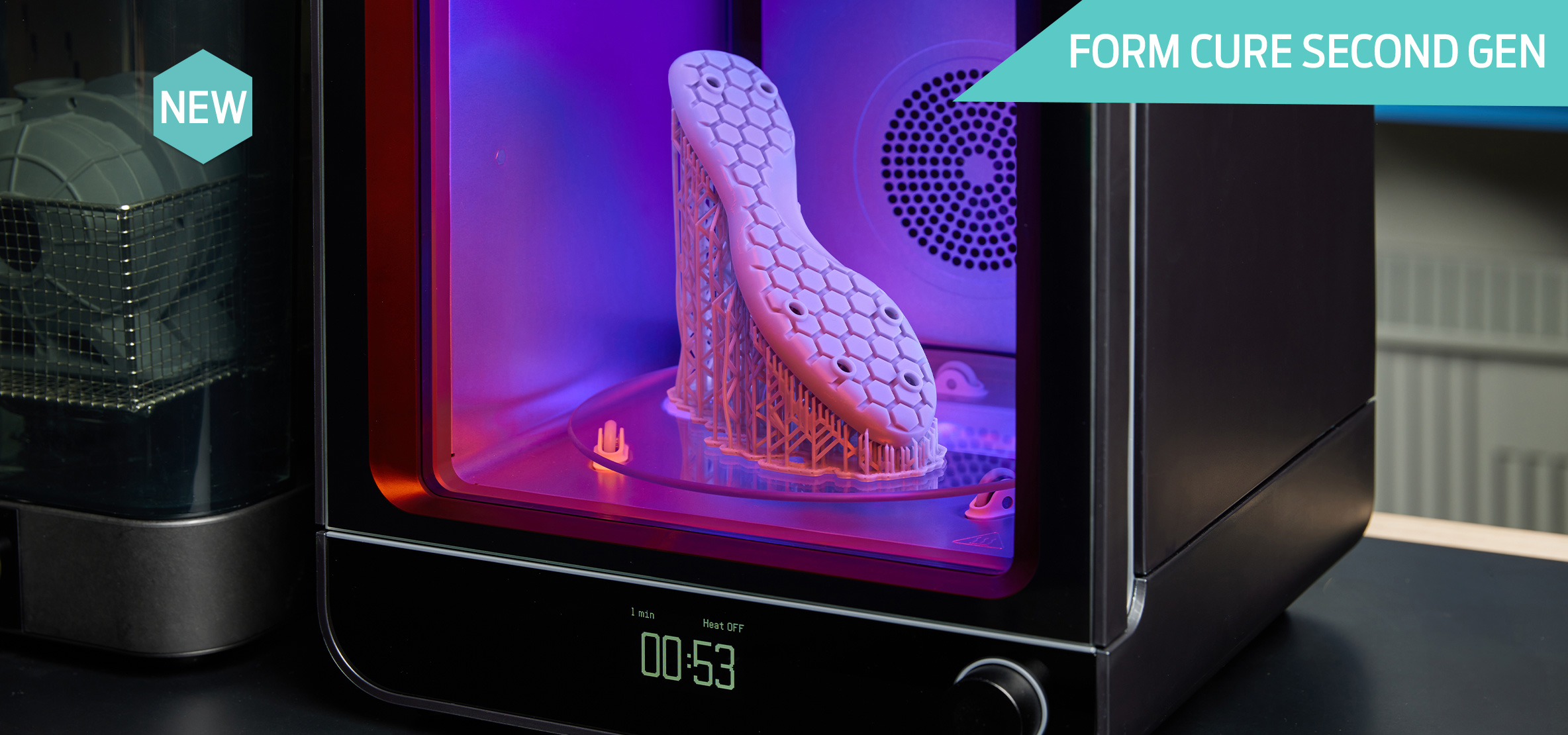

Second generation Form Cure: to cure your prints in 60 seconds

We have already seen how fast the Form 4 printer is, but thanks to Form Cure (2nd Generation), the workflow becomes even faster. This solution offers outstanding curing speed and almost instantaneous heating.

Form Cure 2nd Generation is Formlabs’ new curing unit that allows this post-printing operation to be performed in as little as 60 seconds and 2 to 8.6 times faster than the first-generation Form Cure.

With a larger chamber capable of holding any part printed with Form 4 or Form 4B. Form Cure (2nd Generation) precisely combines heat and light at 405 nm to ensure tough, durable parts with unprecedented speed and homogeneity.

Form Cure 2nd Generation cures with 4 times more UV power, 5 times faster heating, and a 1.3 times larger chamber than the previous version.

The new design of the Form Cure (2nd Generation) includes an array of 48 LEDs and a convection heating system, providing uniform UV and heat exposure, with an irradiation of 14.5 mW/cm² and a maximum temperature of 100 °C.

The door with side hinges provides simplified access while taking up a small footprint. The 235-mm rotating platform is made of glass for easy cleaning.

Post-print curing completes the chemical reaction initiated during printing, improving stability, toughness, and heat and creep resistance while making the surface harder and less sticky. For biocompatible materials, post-printing polymerization is necessary to meet safety standards set by regulatory agencies.

To initiate curing, select a validated default setting from those available for the more than 45 Formlabs materials. Advanced users can customize time and temperature to their specific needs.

| Form Cure (1st generation) | Form Cure (2nd Generation) |

Speed comparison |

|

| Grey Resin V5 | 5 min | 1 min | 5 times higher |

| BioMed Amber Resin | 30 min | 5 min | 6 times higher |

| Tough 2000 Resin | 60 min | 7 min | 8,6 times higher |

| High Temp Resin | 120 min | 15 min | 8 times higher |

Manufacturing these electrical connectors in Flame Retardant Resin with Form 4 and Form Cure (2nd Generation) takes almost one-sixth the time compared to the combination of Form 3+ and Form Cure of the first generation. Compared with the combination of Form 4 and first-generation Form Cure, the use of Form Cure (2nd Generation) reduces lead time by almost 50%.

Time for the production of electrical connectors with a layer thickness of 100 μm

| Print time | Washing time | Post-press curing time | Total | |

| Form 4 & Form Cure (2nd Generation) | 1 h 28 min | 10 min | 15 min | 1 h 53 |

| Form 4 & Form Cure (1st Generation) | 1 h 28 min | 10 min | 2 h | 3 h 38 min |

| Form 3+ & Form Cure (2nd Generation) | 9 h 43 min | 10 min | 15 min | 10 h 8 |

| Form 3+ & Form Cure (1st Generation) | 9 h 43 min | 10 min | 2 h | 11 h 53 min |

Want to learn more about the Form 4 and Form Cure second-generation 3D printing system? We are at your disposal for more information: request a contact.

CONTACT US