TITAN EXT 1070 Pellet

The only machine that in one solution 3D pellet, wire and milling machine printing: the Additive and Subtractive hybrid solution

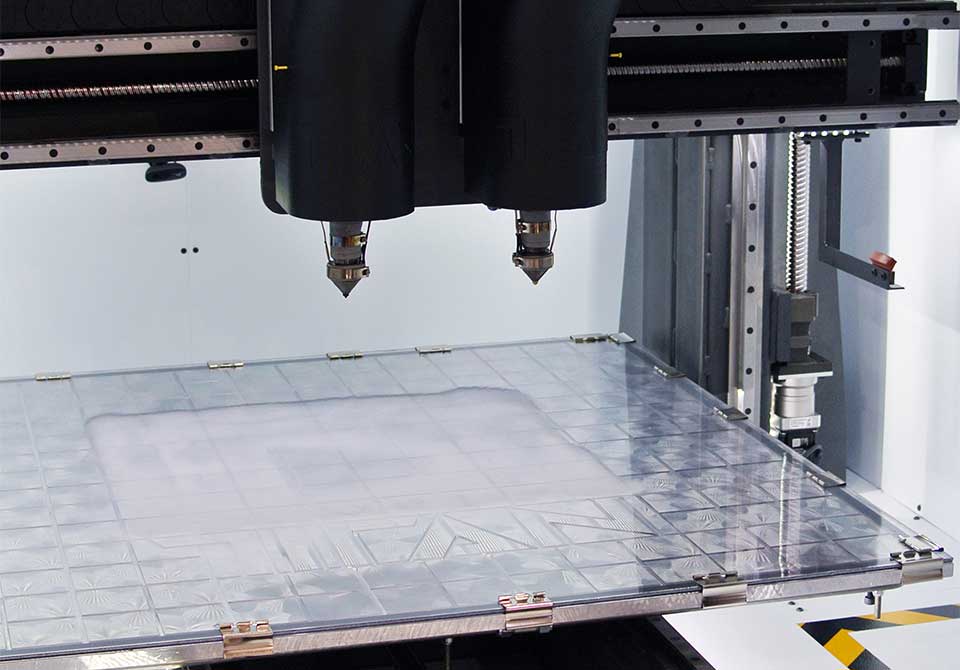

TITAN EXT 1070 PELLET is the high-speed industrial 3D printer for large formats, with an option for CNC milling.

This machine makes it possible to print:

-low cost, thanks to the pellet material

- large-format

- faster than filament 3D printing

- with an open system.

The basic unit consists of a pellet extruder and can be equipped with up to three tool heads.

The modular toolhead system allows the addition of a second pellet extruder, as well as the possibility of filament printing and/or the addition of a 3-axis CNC spindle.

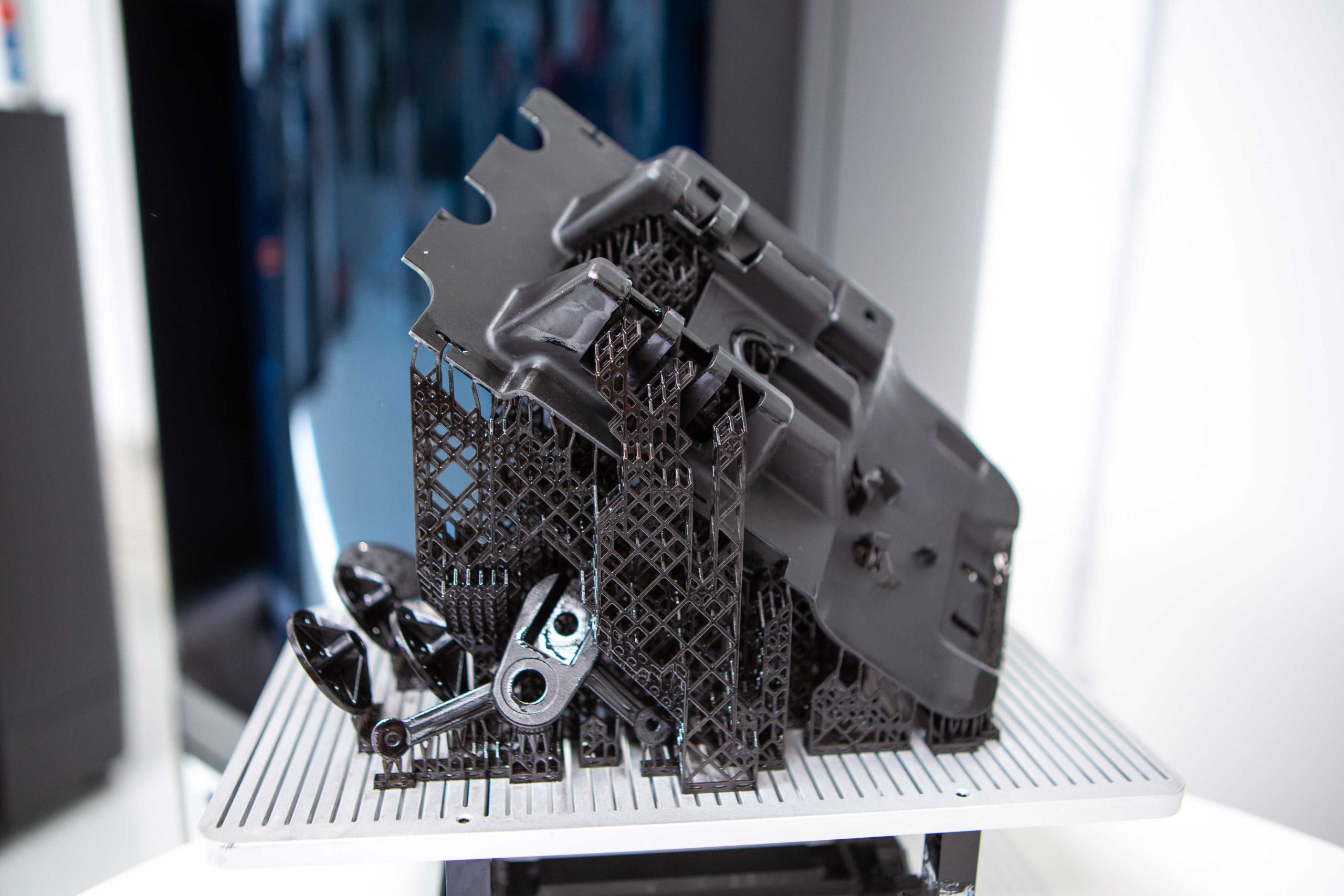

The Titan EXT 1070 printer is ideal for the production of medium to large parts, applications such as production equipment, models and end-use parts, thermoforming molds, and foundry models.

- Print volume

- 1070 mm X x 1070 mm Y x 1118 mm Z

- Cutting volume

- 1041 mm X x 990 mm Y x 990 mm Z

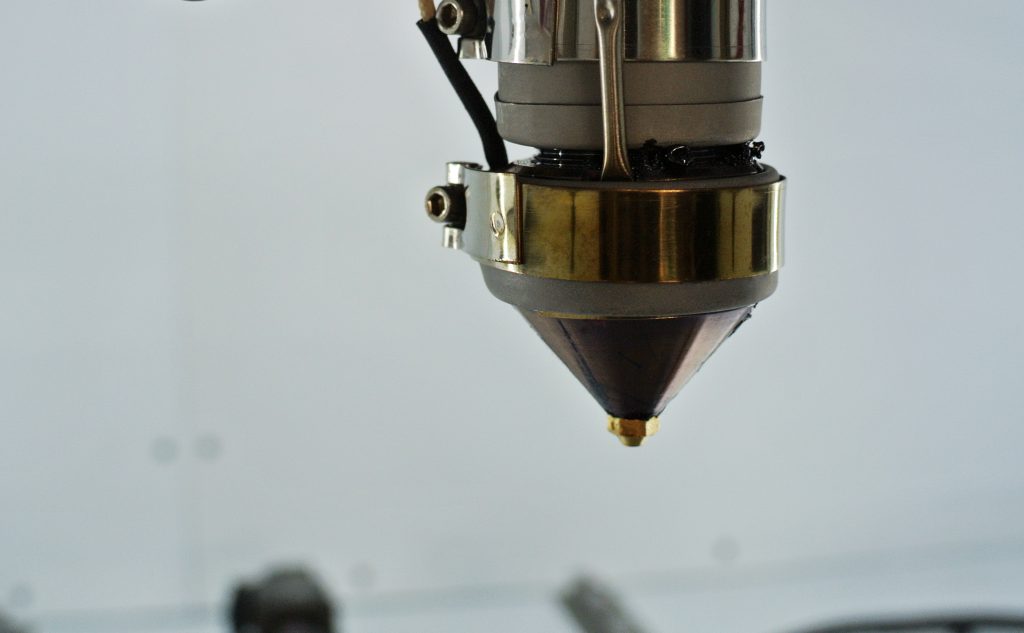

- Nozzle Diameter

- 0,6 mm - 9,0 mm

- Layer height

- 0,4 mm - 6,0 mm

Flexible materials

- TPU

- TPE

- PEBA

- TPC

Standard materials

- PLA

- ABS

- PETG

- PP

- ASA

High-performance/loaded materials

- PC 20% CF and GF

- Nylon up to 50% CF

- PEI 20% CF and GF

- PPS

- PPSU

- PEKK 30% CF and GF

Prototyping

Verify and optimize your design to achieve a product that is perfect in every aspect. 3D printing enables extremely fast, easy and cost-effective production of high-quality prototypes, which are essential for experimenting with alternatives or verifying every functional, aesthetic and design aspect, avoiding slowdowns and errors.

Tooling

Make everything you need quickly and in house easily and inexpensively.

With 3D printing, the tooling of machine tools, the rapid fabrication of parts, complete tools or tools needed for production, can be fully internalized, avoiding the costs of an external printing service and eliminating unproductive wait times.

Produzione

Additive manufacturing wants to propose itself as the production of the future, whether for private use, independent realities or industrial production. Improving industrial productivity through 3D printing and 3DZ offers a wide range of solutions capable of meeting the needs of a variety of professional sectors.

Large format printing

With a build volume of 1070 mm x 1070 mm x 1118 mm, Titan EXT 1070 enables the production of full-size medium to large parts by making them in one piece, without the need to glue the parts together.

10 times faster

The EXT 1070 pellet extrusion printer allows you to print at up to 10 times the speed of traditional filament 3D printing. This will allow you to offer shorter lead times.

10 times cheaper

3D printing with pellets saves money. The cost of pellets is up to 10 times less than traditional raw materials for filament 3D printing.

Designed for production. Ready to do it right away.

The EXT 1070 Titan Pellet printer is an additive manufacturing system for applications such as models, molds, fixtures, jigs, brackets, end-use parts, and full-size prototypes for industries such as foundry, automotive, aerospace and defense, consumer products, and many others.

Wide range of materials

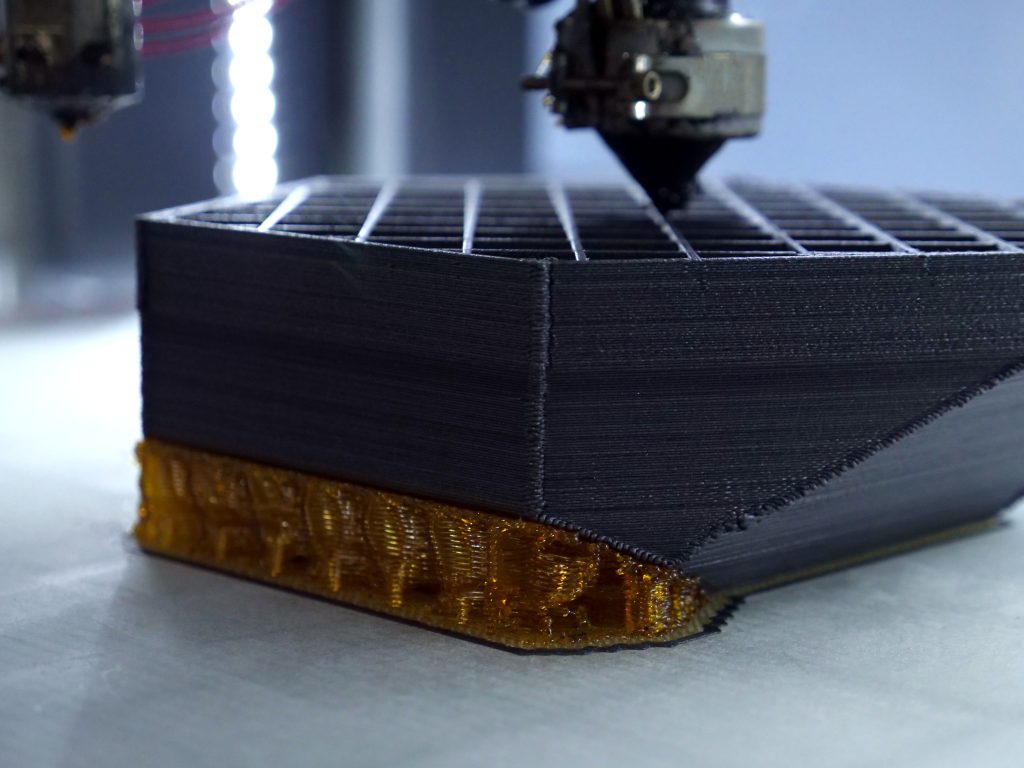

3D printing with a wide range of pellet materials, from basic raw materials to high-temperature and high-performance materials, including CF-PEI, GF-PEKK and GF-PC. Direct extrusion 3D pellet printing on the EXT 1070 also allows the use of highly flexible elastomers and materials with a high percentage of glass and carbon.

It also allows printing with two different materials simultaneously (e.g., one rigid and one flexible).

Hybrid production

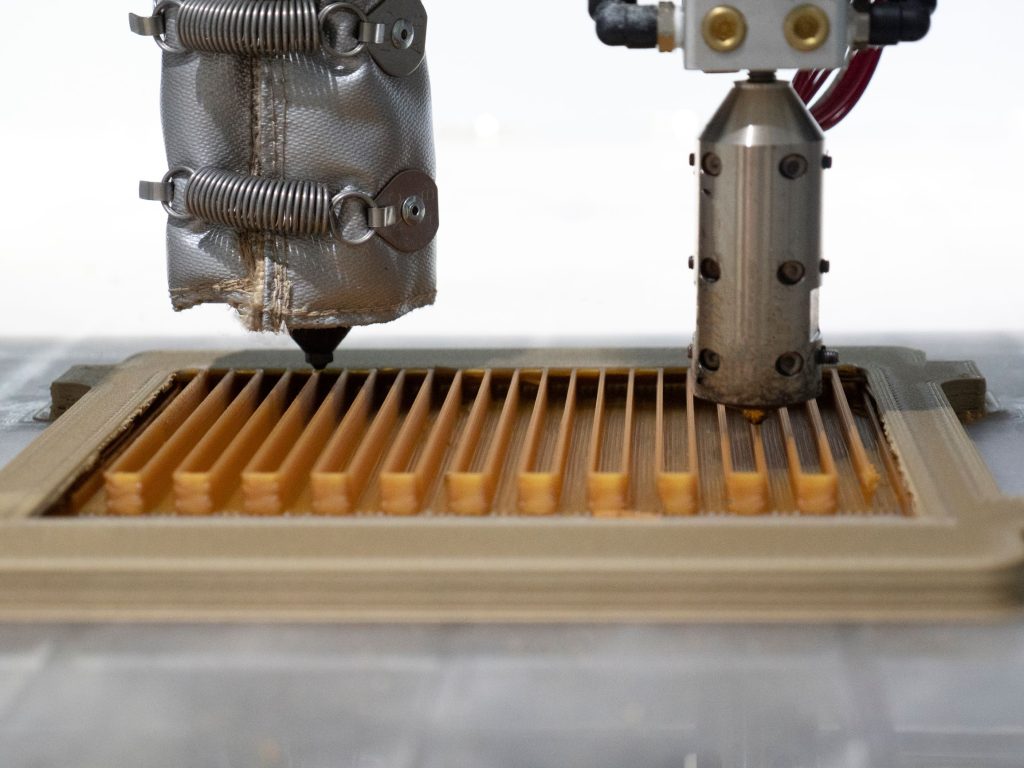

EXT 1070 Titan Pellet can be integrated with additional tool heads on the same gantry. The addition of a filament extruder or a second pellet extruder allows printing with more materials at high speed.

These options can be implemented when the machine is purchased, but also later.

The CNC spindle head enables hybrid production, allowing 3D printed parts to be machined both during and after the printing process.

Rapid production, directly on the farm

The EXT 1070 reduces cycle times and can produce smooth and accurate end-use 3D printed parts, taking additive manufacturing to the next level.

Equipped with a welded steel frame and a heated printing chamber, the EXT 1070 printer enables high-performance functional parts to be made right in your company.

Download

Do you want to know more?

Want to learn more about TITAN EXT 1070 PELLET, the Additive and Subtractive hybrid solution? Contact us: our team of 3D printing experts is at your disposal.