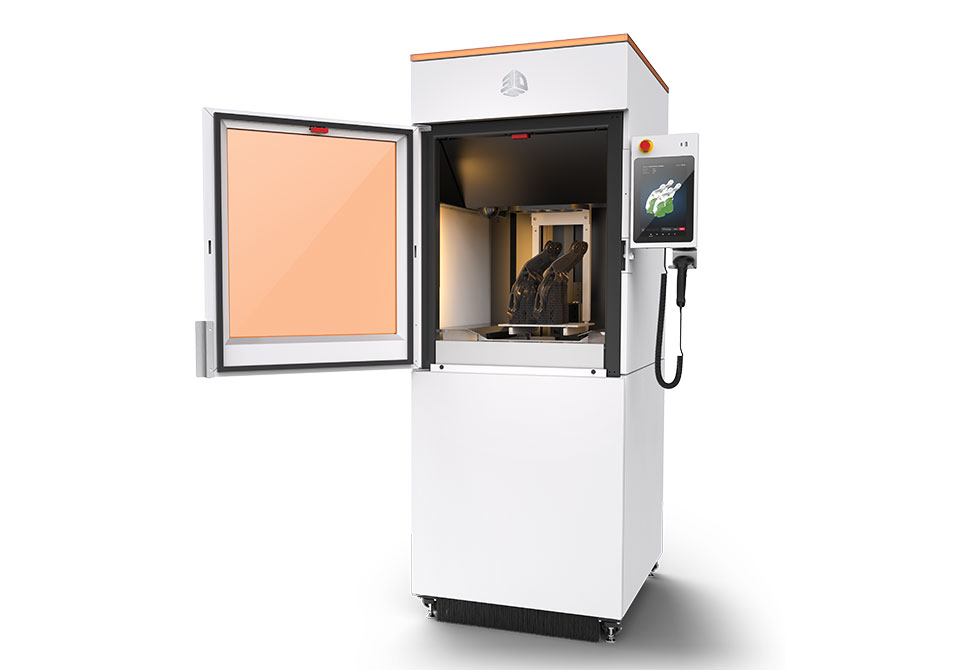

PSLA 270

The most productive industrial 3D printer for pre-series of final components, even large ones

The best of two worlds: the speed of projection 3D printing and the reliability of SLA technology. The PSLA 270 is a next-generation SLA 3D printer, equipped with high-speed projector technology, for fast and precise additive manufacturing. Ideal for companies requiring fast production times and high volumes of parts. This solution, compact but with a good print volume, offers exceptional versatility at a competitive cost, making it perfect for the needs of different industrial applications.

- Print volume

- 242 x 265 x 300 mm

- Technology

- SLA with 7 w dual-track HD projectors

- Resolution

- pixel size 90 µm

- Accuracy

- +/- 100 µm <25 mm, +/- 0,2% >25 mm

- Layer thickness

- 50-150 µm

- Recoater

- double-guided

- Material Refill

- automatic or manual

- VAT capacity

- 55 l

- Speed

- up to 38 mm/h

Figure 4 PRO-BLK 10

Additive manufacturing material with mechanical properties similar to thermoplastics and long-term environmental stability.

This versatile, rigid, heat-resistant material combines speed, strength and excellent mechanical properties and is therefore suitable for direct production of parts.

Figure 4 RIGID WHITE

Matte white rigid resin, for production parts

This biocompatible material offers a smooth surface finish, long-term environmental stability and a clean, long-lasting white color.

Save on costs and tooling times by directly producing 3D printed end-use parts.

Figure 4 RIGID GRAY

High contrast gray resin with balanced thermal and mechanical properties for long-lasting parts.

Save on costs and tooling times by directly producing 3D printed end-use parts.

Figure 4 HI TEMP 300 AMB

Industry-leading rigid resin, resistant to very high temperatures and suitable for the most difficult thermal environments.

It is ideal for use in HVAC systems, appliances, motor casings, stators and molds.

Translucent amber plastic with high thermal resistance for flow visualization (HDT >300 °C)

Prototyping

Check and optimize your project, to obtain a perfect product in every respect. 3D printing allows you to create high-quality prototypes extremely quickly, easily and conveniently, which is essential for experimenting with alternatives or verifying every functional, aesthetic and design aspect, avoiding slowdowns and errors.

Production

Additive manufacturing wants to present itself as the production of the future, whether it is for private use, independent companies or industrial production. 3DZ offers a wide range of solutions capable of meeting the needs of a variety of professional sectors.

3D Sprint

PSLA 270 uses 3D Sprint™, advanced software from 3D Systems for preparing, editing, printing and managing files from a single, intuitive interface. In fact, 3D Sprint allows the customer to significantly reduce the management costs of 3D printers, eliminating the need for expensive software from third-party suppliers. 3D Sprint also automatically generates exceptionally efficient supports that require much less material, increasing savings and avoiding waste.

PSLA 270 is an accurate, high-speed projector-based 3D printer that achieves up to five times higher output than laser technology.

The dual 7-watt HD projector reduces curing times and, with a resolution of 90 µm per pixel, ensures excellent print quality and repeatability.

It is designed for time-demanding, high-volume customers.

Despite being compact, it has a large print volume.

PSLA 270 has a wide range of printing materials.

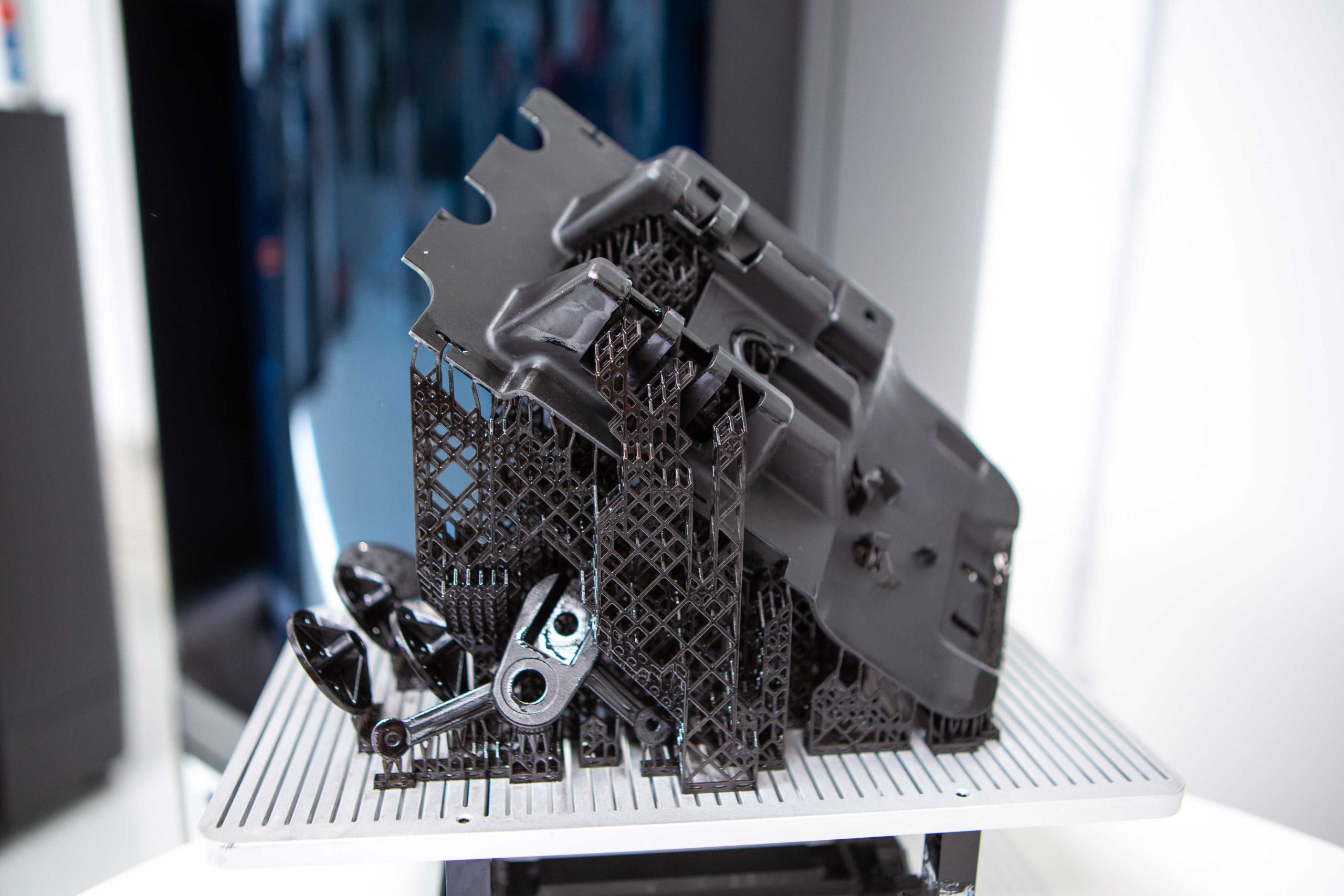

PSLA 270 is compatible with the Figure 4 resin range, ideal for engineering and manufacturing applications. Thanks to these materials it is possible to obtain molded parts of quality similar to injection molding and an exceptionally smooth finish. Printed parts provide long-term mechanical and UV stability, up to 8 years for indoor use and 1.5 years for outdoor exposure according to ASTM D4329 and ASTM G194 methods.

Parts produced with the PSLA 270 exhibit exceptional quality and precision, both thanks to the HD projectors and the innovative hardware configuration. Image processing software automatically adjusts pixel edges with a grayscale, ensuring higher-quality surfaces for end-use parts.

PSLA 270 offers reliable results, and consistent repeatability up to 6 Sigma levels across multiple printers. Whether building large single parts or populating a platform with large quantities of small components, the PSLA 270 ensures consistent performance.

The PSLA 270 features a movable cart that can accommodate different tub sizes to suit your applications. The integrated material dispensing system allows quick changes, without the need for cleaning, ensuring a continuous workflow.

Download

Do you want to see the quality of PSLA 270 live?

If you want more information on this new 3D printer and want to personally appreciate the quality of the pieces printed with PSLA 270, contact us for a no-obligation appointment.