Magics 28

The best software for editing and repairing 3D files

Materialise Magics is intelligent and versatile software for preparing data and processing STL files for 3D printing, featuring an intuitive and customizable user interface. This industry-leading software guides you efficiently through every step of your Additive Manufacturing (AM) workflow.

Some new features of Materialise Magics 28 are:

- Advanced and fast file repair functions

- Improved and optimized 3D nesting management

- Automated reporting management

What's new in Magics 28

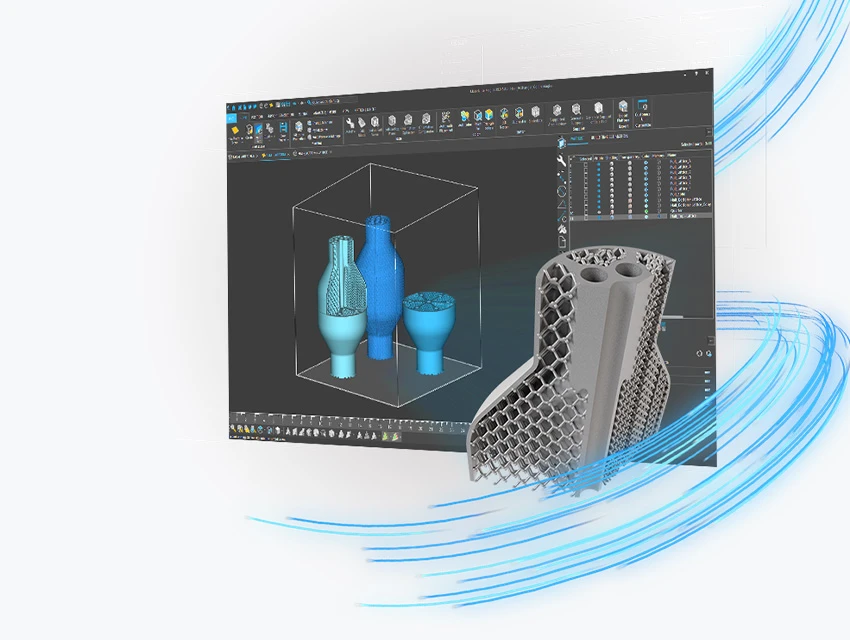

- Lattice structures

- Improved nesting

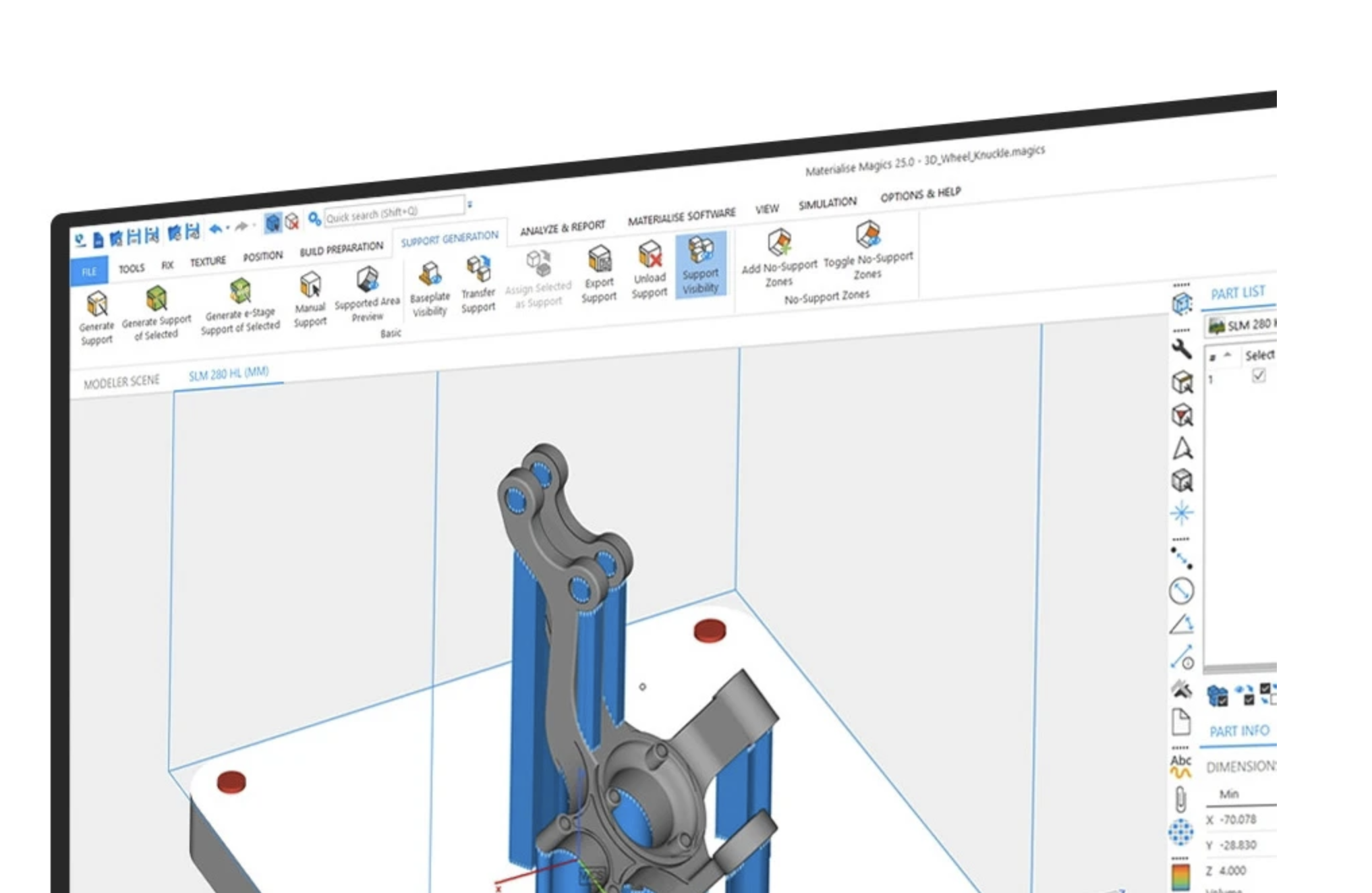

- Improved usability

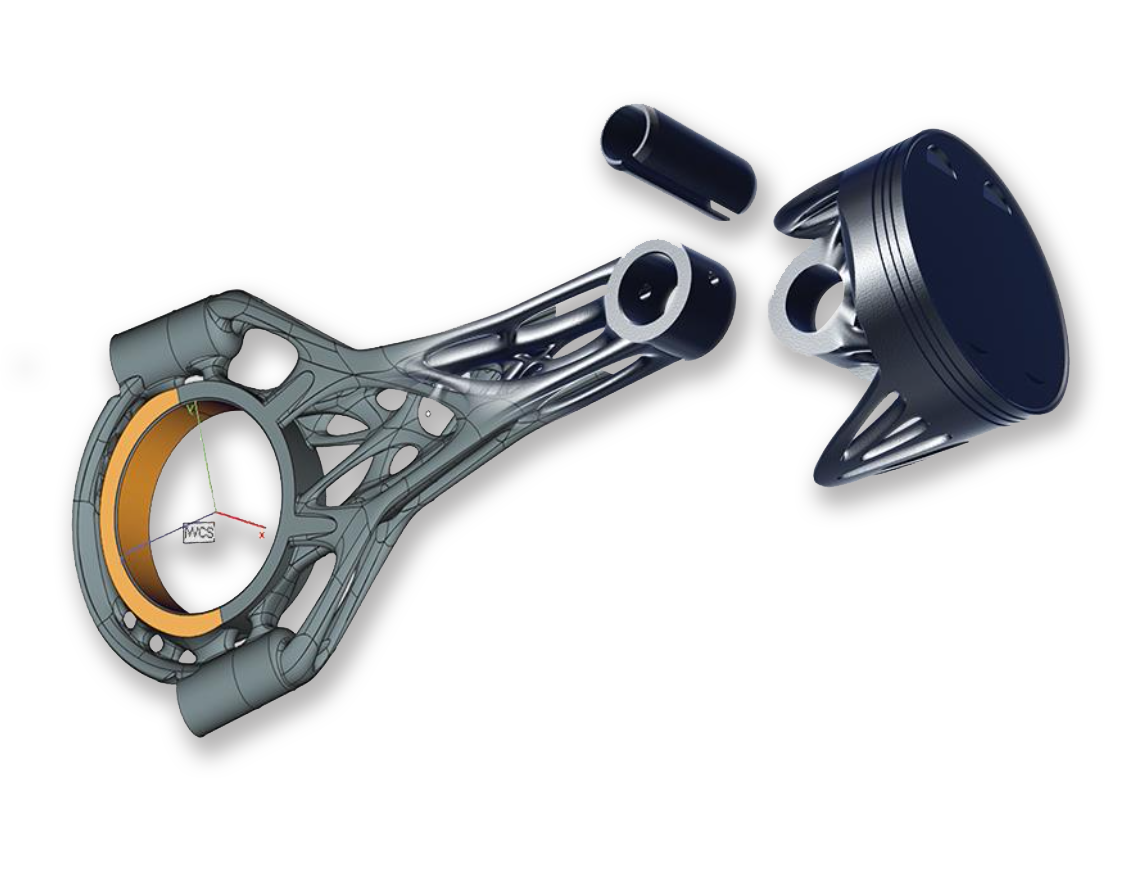

- Improved metal workflows

Explore the new features of Magics 28

- Dark Theme: Improves visibility and visual comfort during prolonged use of the software.

- Universal Reticle Module: A single module that integrates crossbar and slice-based reticles, improving reticle management.

- UI/UX Optimization: Improved import windows and increased workspace with minimized tools.

- CO-AM integration: More options for opening and managing imported parts.

- Slice-based 3D plots: Enables management of 3D plots without creating large mesh files.

- Improvements in Marking: Improved handling of original BREP faces and mesh conversions.

- Improvements in Cutting: New dialog boxes and improved accuracy in cutting parts.

- Improvements in Label Scheduling: Reduced run times and improved memory utilization for large mesh parts.

- Contactless Media: Hybrid media to reduce post-processing.

- Nester: New 3D Nester window and organic Sinterbox to optimize part nesting.

Materialise Magics 28

Why Magics 28?

Materialise Magics 28 introduces several new features and improvements to optimize the user experience and increase productivity in preparing parts for additive manufacturing.

Usability and User Interface

Dark theme: Magics 28 introduces a dark theme designed to reduce eye fatigue during prolonged use of the software, especially in dimly lit work environments.

UI/UX optimization: Import windows have been improved to provide a better overview of parameters, while the workspace has been expanded with the ability to minimize tool sheets.

Productivity

Universal Lattice Module: The new lattice module integrates all the tools needed to create meshes, including traverse and slice-based meshes, enabling more efficient management without the need for additional software.

Slice-Based 3D Plots: This feature allows plots to be transformed into slice-based 3D plots, avoiding the creation of large mesh files and allowing quick cutting with the Materialise Build Processor or Slice Magics Module.

Improvements in Label Planning:

Significant performance improvements with reduced execution time and memory usage, making the labeling process more efficient.

Preparation of the Parties

Improvements in Cutting: New dialog boxes and elaborate tooltips improve the user experience by providing more precise control when cutting parts.

Contactless Media:

Introduction of hybrid supports that reduce the need for post-processing, improving the overall quality of the parts produced.

Advanced Features

CO-AM Integration: More options for opening and managing imported parts, allowing greater flexibility during import.

Advanced Nester: New features such as the Organic Sinterbox and 3D Nester window improve the nesting process, optimizing space utilization and better protecting parts during production.

Efficiency

Enhanced Media Generation: Includes features to preserve media during fitting, beveling and labeling operations, as well as options for manually cutting media to speed up workflow.

Materialise Magics 28 offers a wide range of enhancements that make the software more intuitive, efficient and powerful, adapting to the growing needs of the additive manufacturing industry.

Whether you are doing file imports, print slicing or anything in between, Magics provides you with the right tools.

Get outstanding accuracy throughout your workflow by defining the parameters best suited to your prints.

It automates processes with specialized modules that reduce preparation time and increase production speed.

Whatever technology or material you use, we offer a single solution that meets all your needs.

Import almost any file format, preserve native color information, and retain control of your original data.

It ensures that parts are printable in high quality, with features such as automatic repair execution, offsets and lattice structures.

Accurately perform operations such as slicing and orientation and clearly communicate the information to your machine.

Keep track of printouts and ensure repeatability with automated reports that require minimal human intervention.

Nest your parts with Magics for increased speed and advanced workflow control.

Streamline the creation of support structures and reduce the time required.

Avoid costly print failures by using analysis functions that identify potential problems.

Contact us to get more information and request a quote