Designer Sven Götti

“We were faced with a great challenge: we wanted to dye 3D printed eyeframes in any color of our choice.” These were the words of Sven Götti, CEO of Götti, the largest Swiss manufacturer of eyeframes that combines artisanal precision and constant innovation.

Since its inception, Götti has focused on innovation, quality and continuity. All models have been designed under the guidance of Sven Götti for over 25 years. Today Götti supplies selected specialist dealers in more than 40 countries.

The aesthetics, the zeitgeist, the materials, the refined mechanical solutions and the possibility of 3D printing, are the formula for making unique eyeframes. An unmistakable expression of security, style, quality and Swissness.

In addition to a wide range of acetate and ultra-lightweight titanium frames, Götti’s “Dimension” collection features 3D-printed spectacles.

New technologies for high demands: the new 3D eyeframes

Götti’s great challenge began in 2014. At that time, the company launched a sports eyewear project using 3D printing technology for the first time. It was clear from the outset that the use of this technology brought many advantages, including the flexibility and lightness of the material.

Despite the great results immediately achieved with 3D printing, at the time there was no industrial dyeing solution that could meet the demands of the manufacturer of custom color eyeframes. In addition to the individual requirements to be met, it was more a matter of finding materials that did not irritate the skin and were allergen-free.

The demands on finishing were demanding right from the start and the developers were unable to find a solution. After a long search, Götti finally came across DyeMansion.

The eyeframes manufacturer finds the answer in the partnership with DyeMansion

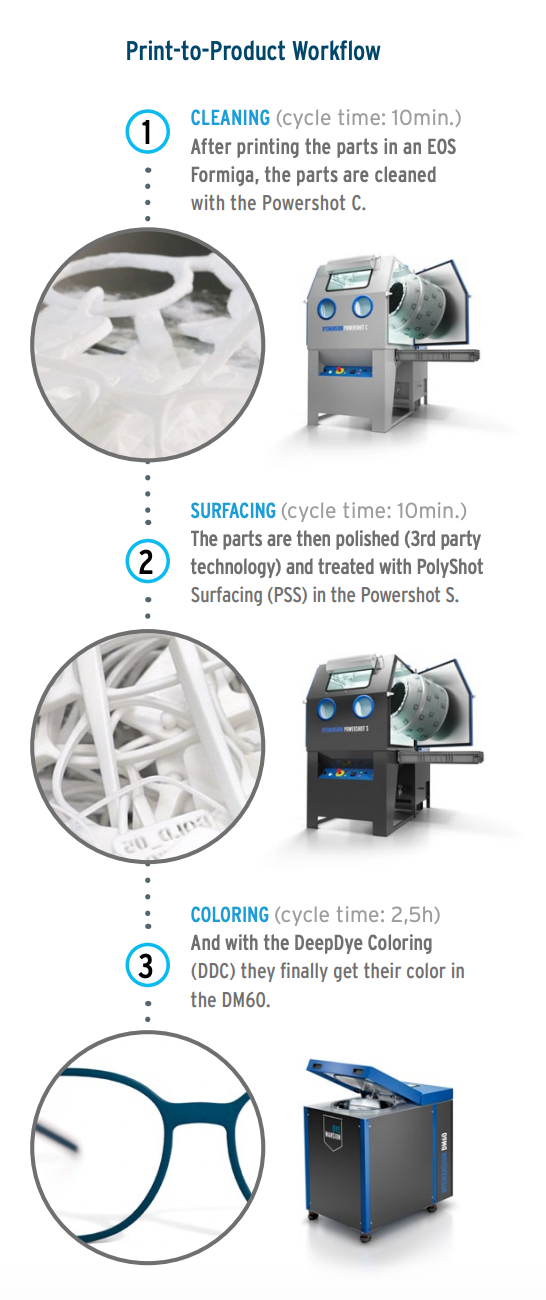

The successful implementation of DyeMansion’s print-to-product workflow consists of the Powershot C and Powershot S sandblasting systems, as well as the Powershot C and Powershot S sandblasting systems. The DM60 dyeing system has achieved an ideal surface finish for the frames and a homogeneous and reproducible colouring, giving rise to a collection of eyeframes that can be marketed with 3D printing.

From the raw piece printed in 3D to the high value product:

The perfect finishing for the surface of the frames is achieved through a combination of grinding and Dye-Mansion PolyShot Surfacing with the Powershot S.

After producing the individual parts of the eyeframes on an EOS Formiga, the powder is first removed with the DyeMansion Powershot C (1), then polished, treated with the PolyShot Surfacing (PSS) in the Powershot S (2), and finally dyed with the DeepDye Coloring (DDC) process in the DM60 (3). To achieve the desired gloss appearance, the pieces are then treated again in the Powershot S with PolyShot Surfacing. Then the individual parts (frame and rods) are assembled, the lenses inserted and the eyeframes packed for shipping.

“The Dimension collection printed in 3D was very well received by the end customers. Not only because of the eye-catching trendy colours, but also because of the lightness and flexibility of the material, which guarantees a high level of comfort,” says Sven after the products became marketable thanks to the possibility of having exclusive eyeframes for consumers.

The new 3D eyeframes

The advantages of 3D printing & DyeMansion technology for eyeframes manufacturer Götti and its customers have been:

- MAXIMUM INDIVIDUALITY

- SPECIALLY DESIGNED COLOURS

- SKIN COMPATIBILITY AND LIGHTFASTNESS

- EXCEPTIONAL DESIGN

- INNOVATION CYCLES

New projects are possible thanks to the use of 3D printing technology and DyeMansion. Models can be designed without having to consider material deviations, such as abrasion or paint application. This allows new options for coupling frames and temples, while reducing design complexity. Götti is able to respond more quickly to market needs and changing trends. Compared to conventional production methods, model designs can be quickly adapted, tested and produced under real-world conditions as needed.