Trends for 3D printing in 2025 according to 3D Systems: innovation, advanced materials and automation.

Throughout 2024, additive manufacturing has solidified its strategic role in many industries, bringing innovation and greater efficiency to manufacturing processes. According to experts at 3D Systems, a leader in 3D printing and a longtime partner of 3DZ, 2025 will be a year of further evolution, with new applications and technologies transforming the way critical components are designed and manufactured. 2025 will mark an acceleration in the adoption of additive manufacturing in high-reliability industries, bringing new opportunities in markets such as energy, semiconductor, aerospace and defense.

According to Jeffrey Graves, CEO of 3D Systems, companies are overcoming traditional barriers by integrating 3D printing into their manufacturing processes with faster, more reliable and scalable solutions.

Innovative materials and new applications for semiconductors and HPC

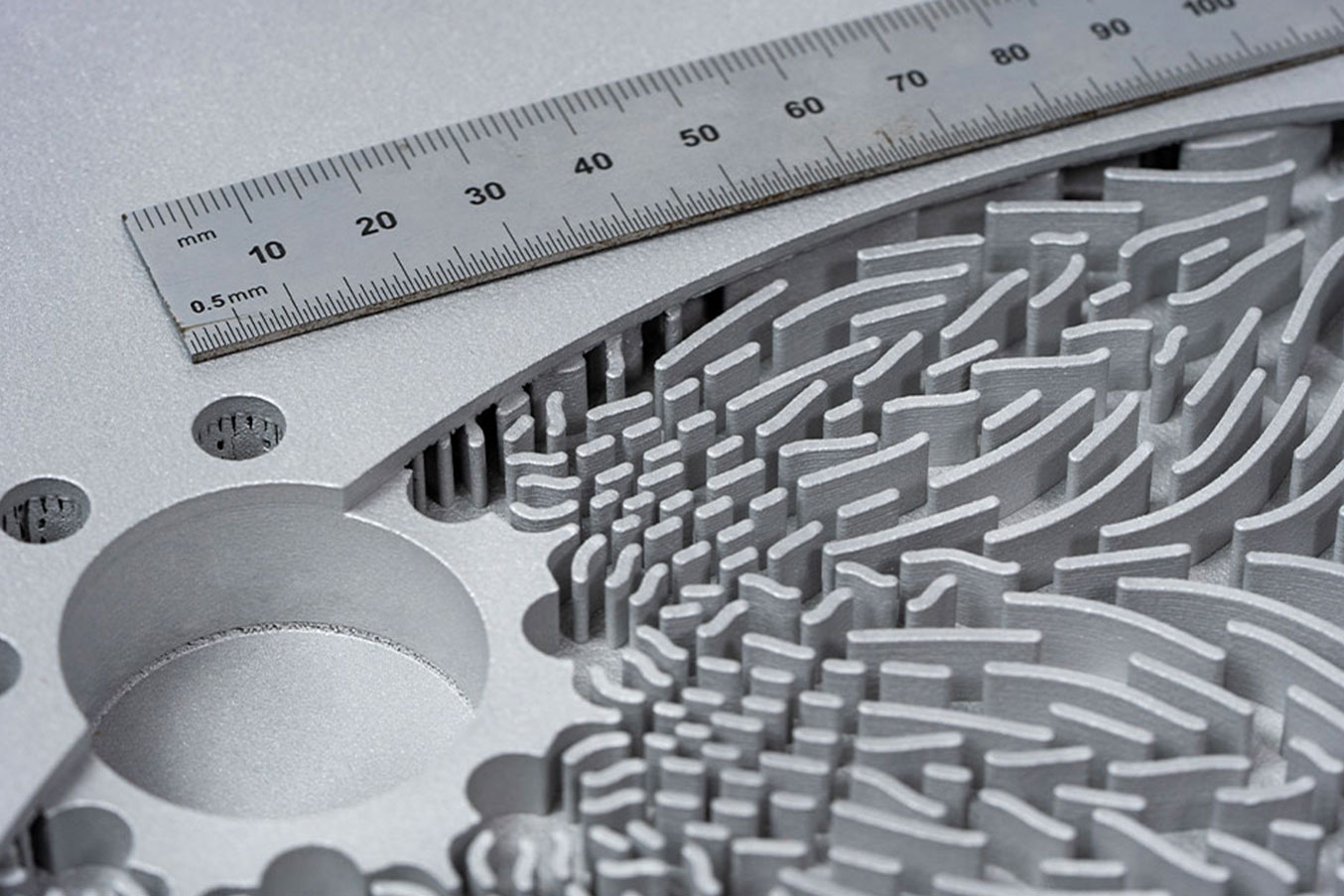

The semiconductor and High Performance Computing (HPC) industry is investing large sums to meet the growing demand for advanced thermal management. 3D printing plays a key role in optimizing heat sinks, custom cooling channels, and precision electronic components, ensuring tailored solutions for high-performance devices.

The expansion of 3D printing in precision industries

Aerospace, defense and automotive are increasingly leveraging additive manufacturing to make critical components, reducing costs and production time. According to 3D Systems, 2025 will see growth in the use of 3D printing for the production of off-the-shelf parts, casting molds and manufacturing support equipment, transforming workflows with greater efficiency and flexibility.

The future of 3D printing: advanced materials, software and automation

Innovation in photopolymer materials and projector-based 3D printing systems will replace many traditional technologies, increasing speed, yield and component quality. Joe Zuiker, EVP Engineering & Operations at 3D Systems, envisions a future in which 3D printing will be increasingly driven by generative design and advanced software, optimizing every step of the manufacturing process.

New photopolymer materials, already available or under development, are improving the performance of 3D printing, offering greater strength, durability and flame retardance. Advanced research on light-based digital manufacturing is also opening up new possibilities with innovative catalysts and multifunctional polymers, expanding the range of attainable properties and industrial applications.

Automation and digital integration for more efficient production

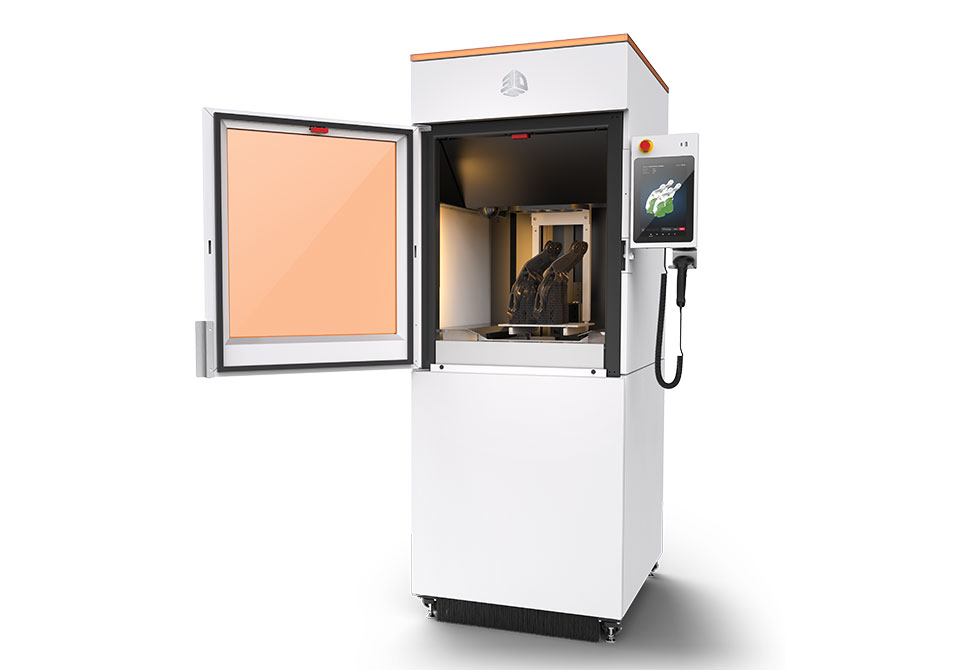

The year 2025 will see increased automation of 3D printing processes, with software capable of managing and optimizing the workflow from concept to production. The integration of hardware, software and materials will make 3D printing an increasingly indispensable technology for manufacturing companies, improving efficiency, reducing waste and accelerating time-to-market.

3DZ, an official 3D Systems reseller, is ready to support companies in adopting the most advanced 3D printing solutions. The future of manufacturing is already here: discover with us the additive technologies that are revolutionizing the industry 🚀