Professional metal 3D printers

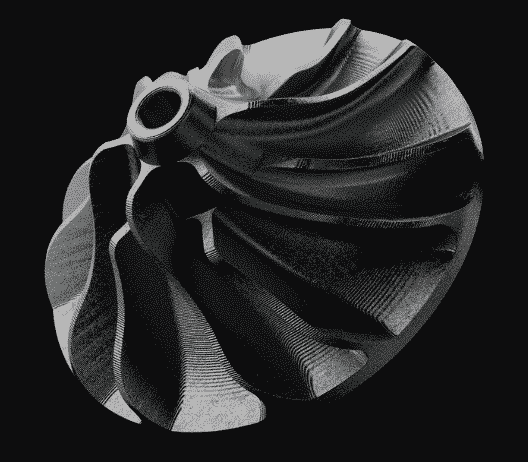

3D metal printing has now acquired a key role in the prototyping and production processes of many companies in the most varied industrial sectors. This printing technology is particularly valid for the production of high quality functional parts with extremely precise details.

Metal 3D printers open the horizon to a new way of designing, prototyping and manufacturing. In fact, the creation of metal objects using traditional processes has always been expensive, time-consuming due to the high waste of metal material during the actual production phase.

But in 3D metal printing, there is no more waste: all the material is used for the object to be printed. The unused metal powder can be recovered and used again after reconditioning the powder.

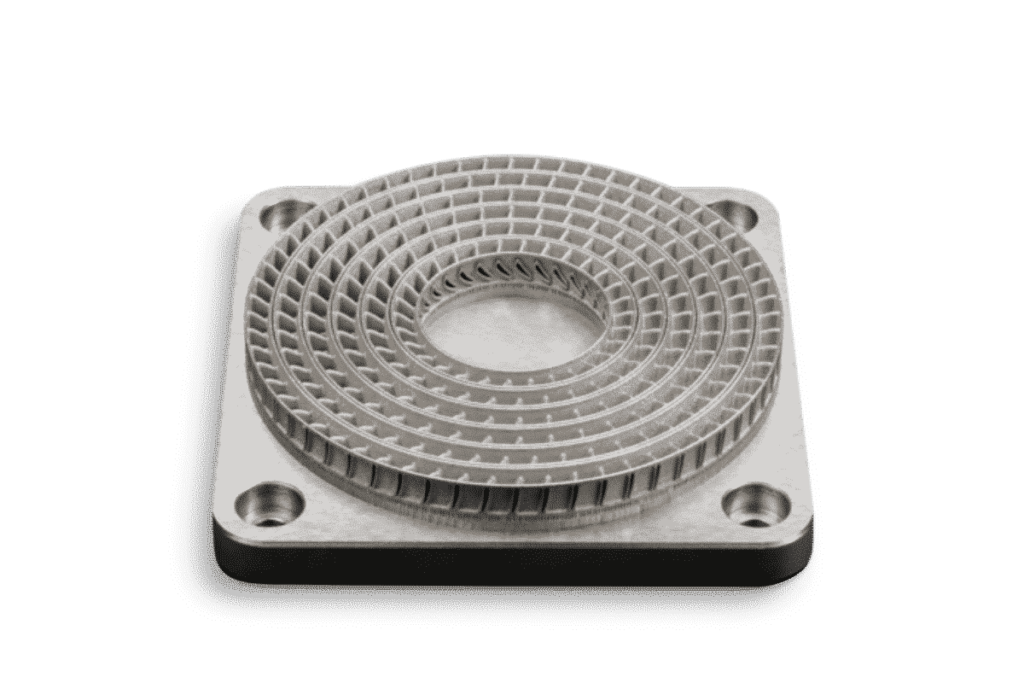

The additive metal production also allows to design and obtain parts up to 60% lighter than traditional production. All this without compromising the mechanical properties of the final part. Think for example of metal 3D printed parts in metal with internal honeycomb structure: this type of realization would have been unthinkable with the design limits of traditional methods.

So let’s see which are the metal printers in the 3DZ catalog and what their main features are.

Metal X

The complete solution for 3D metal printing by Markforged. This machine allows you to go from design to fully functional metal parts in less than 24 hours. All this with a much more affordable investment than other metal printing technologies. The other advantage of the Metal X is Eiger, the most advanced printing software, which allows you to print metal components directly from your browser.

With Metal X you can print from a wide range of available materials, including pure copper, inconel 625 and stainless steel.

DMP Flex 100

DMP Flex 100 is the “little one” in the Direct Metal Printing (DMP) family, the entry level printer for 3D Systems‘ additive metal production. It allows to obtain parts with an excellent surface finish that therefore require less post-processing. Thanks to the unique powder deposition system, DMP Flex 100 allows angles of up to 20° to be produced without the use of supports, which results in material, time and cost savings.

ProX 100

The smallest 3D printer in the ProX DMS line is the ProX 100, designed as a starting point for those who want to produce small but complex metal parts with high levels of quality and speed. It has a print volume of 100mm x 100mm x 80mm, manual loading of materials and an external recycling station (optional). It also includes 3D Systems software tools specifically designed to ensure high quality for metal and ceramic products.

DMP Flex 350 and DMP Factory 350

The DMP Flex 350 is the reliable and flexible metal solution designed for 24/7 part production. This printer offers high throughput and repeatability as well as high quality parts. This printing solution, ideal for application development and R&D, is easily scalable and includes a printer with manual powder management, 3DXpert software, Laserform printing materials and qualified support from our team of experts. It is possible to upgrade to the DMP Factory 350 solution.

DMP 500 Factory Solution

DMP 500 Factory Solution allows you to print large metal parts without joining lines. The DMP Factory 500 solution is designed to deliver consistent and repeatable part quality, high productivity 3D metal printing with low Total Cost of Ownership (TCO) and easy integration with traditional metal manufacturing processes. Its function-specific modules are designed to maximize efficiency and optimize use.