Nylon White Food Safe from Markforged: new 3D printing material for the food industry

With Nylon White FS, additive manufacturing overcomes traditional limitations, enabling the production of parts certified for food contact.

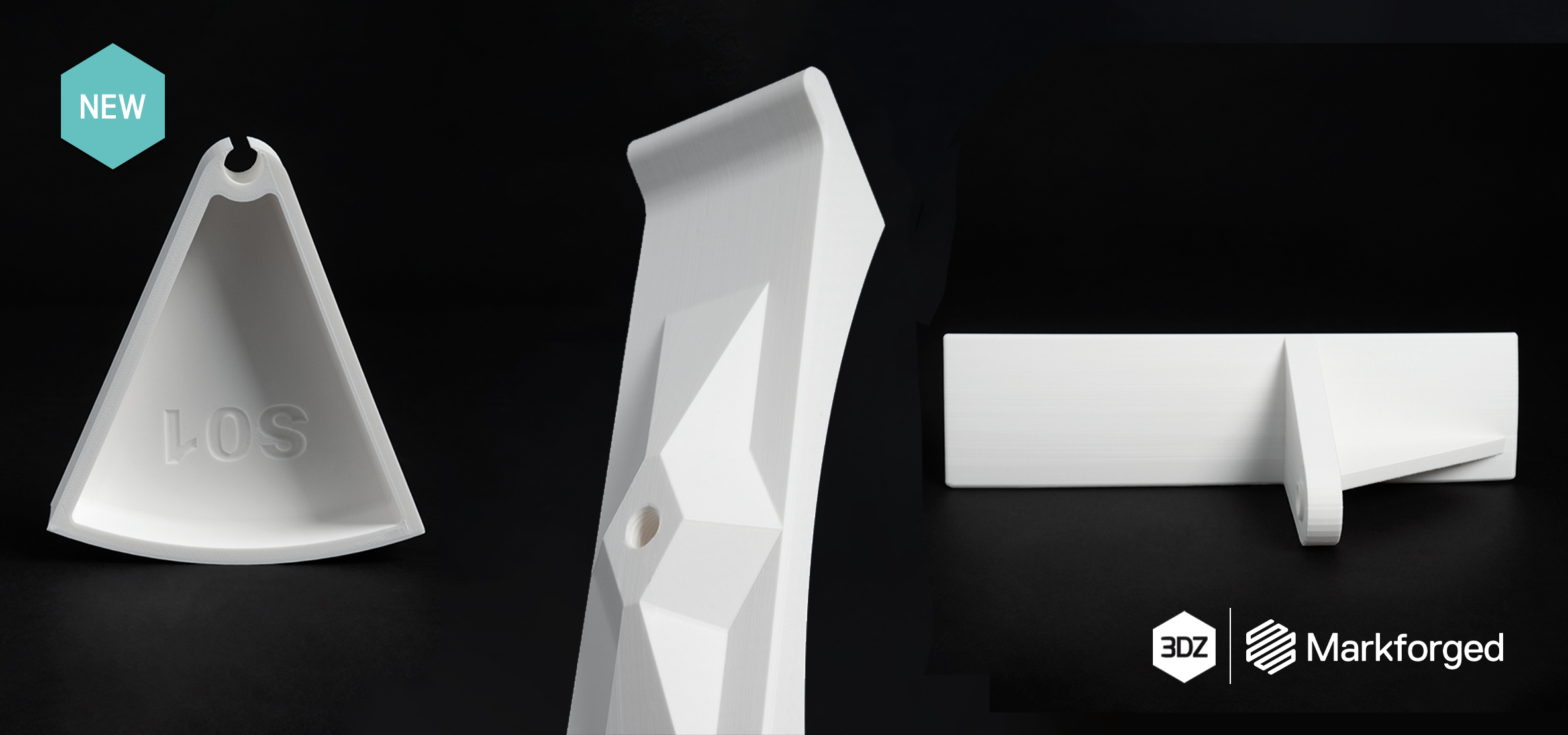

Meet Nylon White FS from Markforged: an innovative solution for the food and beverage industry. This material represents a major step forward for the adoption of 3D printing in production departments, offering a certified food contact option that is ideal for environments where safety is a priority. It opens up new possibilities for efficiency and innovation in the production chain.

What is Nylon White FS?

Nylon White FS is a non-abrasive, unfilled nylon that is NSF/ANSI Standard 51 certified and FDA CFR Title 21 compliant. It has undergone rigorous testing to ensure safety and ease of cleaning, making it ideal for applications that require approved food contact materials, such as the manufacture of tools and components for food industry plant maintenance.

Nylon White FS is compatible with the FX10 3D printer, the world’s only printer capable of printing both polymers, composites and metal.

What are the ideal applications for Nylon White FS?

This material is perfect for production support and plant maintenance, such as guiding and pushing tools on conveyor belts, channels, funnels, and other fabricated media. Nylon White FS is suitable for both indirect (Zone 2) and, with proper corporate safety procedures, direct contact (Zone 1) food and beverage applications.

What are the advantages of using 3D printing for the food industry?

-

Reduced production time and inventory costs

3D printing enables on-demand parts to be produced directly on-site, reducing the need to maintain high inventories of spare parts, limiting the costs associated with oversized inventories, and avoiding the wait times typical of outside supplies.

-

Increased manufacturing flexibility and customization

Additive manufacturing makes it possible to design and produce highly customized parts that perfectly match specific production requirements. In production lines in the food industry, components such as guides, channels, and packaging equipment can be optimized to improve operational efficiency and reduce downtime.

-

Rapid interventions to minimize downtime

In food processing settings, time is a crucial factor. With 3D printing, you can respond quickly to part failures or wear and tear by quickly printing the spare parts needed to restore production line operations. This helps minimize disruptions, reducing operating costs and keeping productivity high.

-

Improved food safety

Food contact certification allows you to use 3D printing even in critical areas of production, such as packaging and food handling. Thanks to Nylon White FS you can make safe and easily sanitized components while complying with strict food safety and hygiene regulations, a must in this industry.

-

Optimizing line changeover procedures and reducing waste

Thanks to the flexibility of 3D printing, you can design specific parts for production lines that require frequent changeovers, reducing line changeover times and optimizing the use of resources. This results not only in increased efficiency, but also in reduced material and energy waste, contributing to more sustainable production.

-

Experimentation and innovation

The ability to print prototypes and test parts quickly and cost-effectively gives food companies the opportunity to experiment with new designs and continuously innovate their processes. With Nylon White FS, new equipment or components can be quickly developed, allowing them to quickly adapt to new market needs and regulations.

The adoption of Markforged’s Nylon White FS thus opens up new perspectives for additive manufacturing in the food industry, allowing processes to be optimized, costs to be reduced, and the needs of increasingly dynamic and regulated production to be met quickly and safely.

For more details or to find out how to integrate Nylon White FS into your production, contact us-we are here to support innovation in your company.

Contact Us