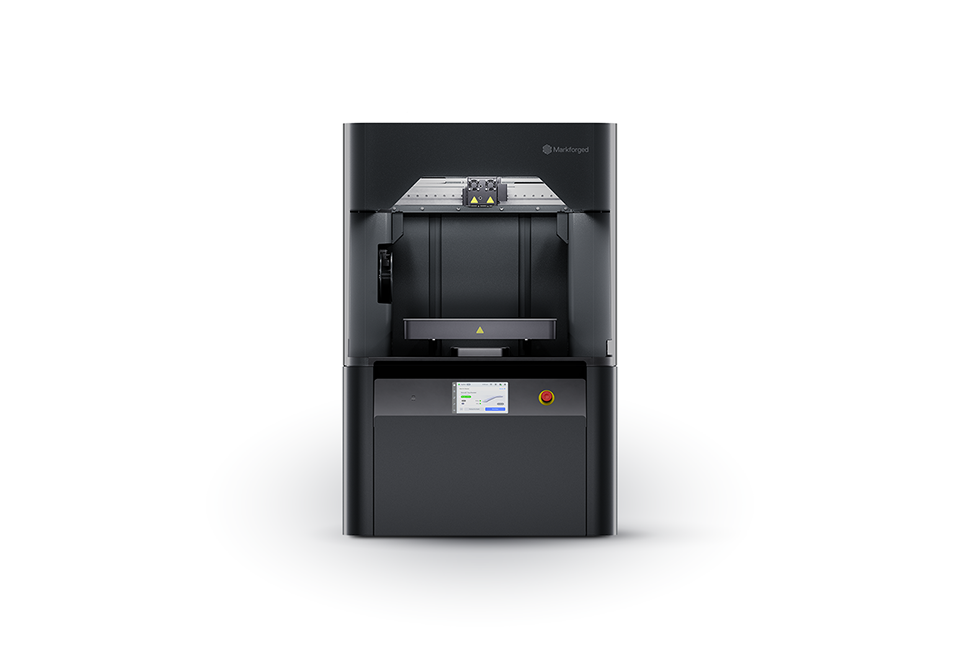

FX10

The industrial 3D printer for your production department

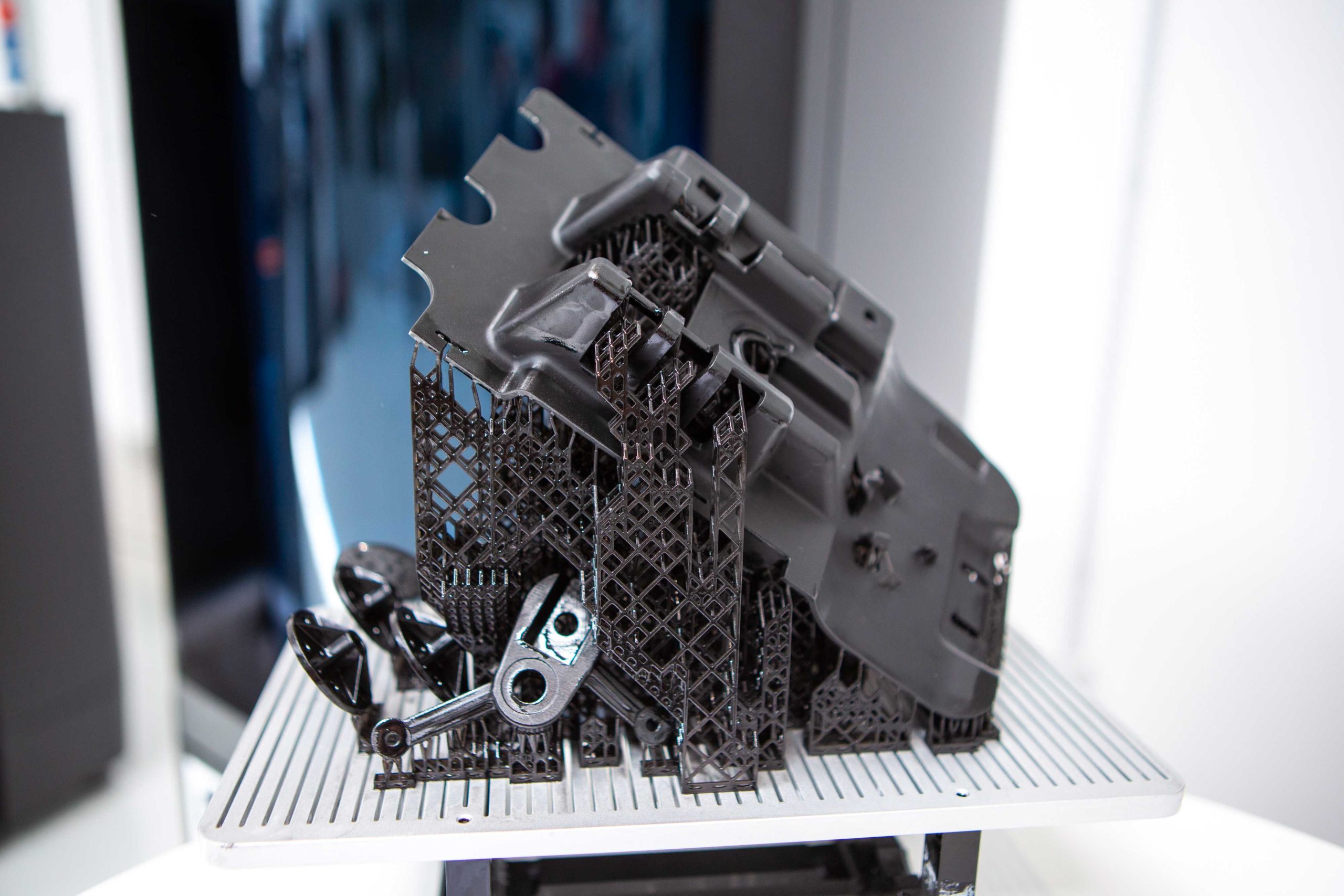

FX10 is an extremely versatile solution designed to print durable and precise parts in industrial environments. FX10 has a large print volume with heated chamber and platen. It is fast and highly automated-its printing process is precise and reliable. It has a laser micrometer that scans parts during printing for quality control and machine calibration

- Print volume

- 375 x 300 x 300 mm

- Printing Technology

- FFF (filament fusion fabrication)

CFR (continuous fiber reinforcement)

- Z-axis resolution

- 125um - 250um

- External dimensions

- 760 x 640 x 1200 mm

Onyx

Carbon microfiber-filled nylon offers an excellent level of heat resistance, surface finish and chemical resistance.

Carbon fiber

Rigid, strong and extremely light, carbon fiber reinforcement produces components that can replace machined aluminum.

Prototyping

Verify and optimize your design to achieve a product that is perfect in every aspect. 3D printing enables extremely fast, easy and cost-effective production of high-quality prototypes, which are essential for experimenting with alternatives or verifying every functional, aesthetic and design aspect, avoiding slowdowns and errors.

Tooling

Make everything you need quickly and in house easily and inexpensively.

With 3D printing, the tooling of machine tools, the rapid fabrication of parts, complete tools or tools needed for production, can be fully internalized, avoiding the costs of an external printing service and eliminating unproductive wait times.

Production

Additive manufacturing wants to propose itself as the production of the future, whether for private use, independent realities or industrial production. Improving industrial productivity through 3D printing and 3DZ offers a wide range of solutions capable of meeting the needs of a variety of professional sectors.

Digital Forge and Eiger

The FX10 operates on Digital Forge: Markforged’s additive manufacturing platform that offers intuitive desktop and mobile software, training, and integrated costing. You can start generating ROI right away and easily scale up to add more teams, machines and facilities.

Eiger is the engine of Digital Forge. It allows you to move smoothly and reliably from CAD design to molded metal, composite, and continuous fiber parts in one simple, intuitive interface.

Printing large-format components in less time

With its generous 375 x 300 x 300 mm print volume that can reach 60°C, the FX10 is almost twice as large as its X7 predecessor. It is capable of printing up to two times faster.

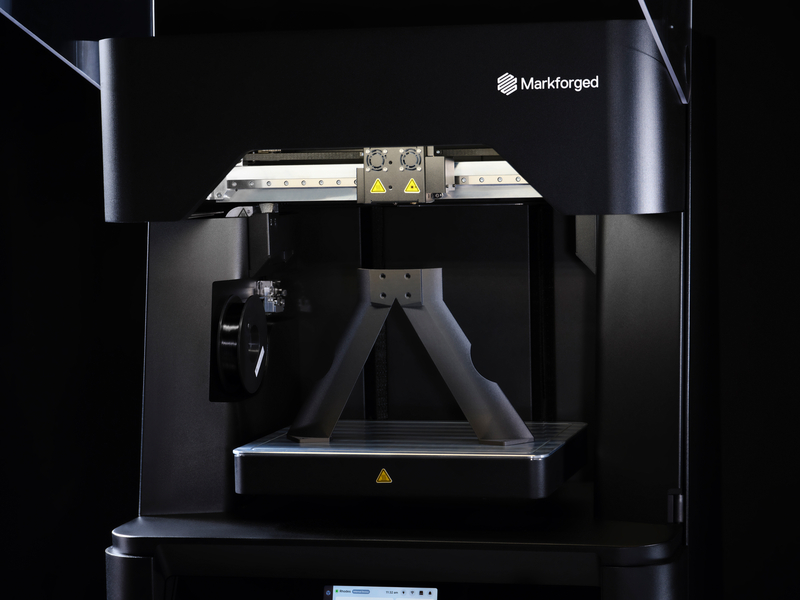

Superior carbon fiber printing

The FX10 takes scalable composite printing higher by combining the strength and durability of Markforged materials with a system designed for accuracy and reliability. FX 10's motion system maintains accuracy even during high-speed printing.

Optical sensors on the printhead for verifiable accuracy

For assurance that 3D printed parts meet the required tolerance requirements, FX10 has two optical sensors that provide visibility into part quality and printer integrity.

During printing, the laser micrometer scans the parts and assists in machine calibration. The data is interpreted by Inspection software for dimensional verification, providing quality assurance as soon as the print is finished.

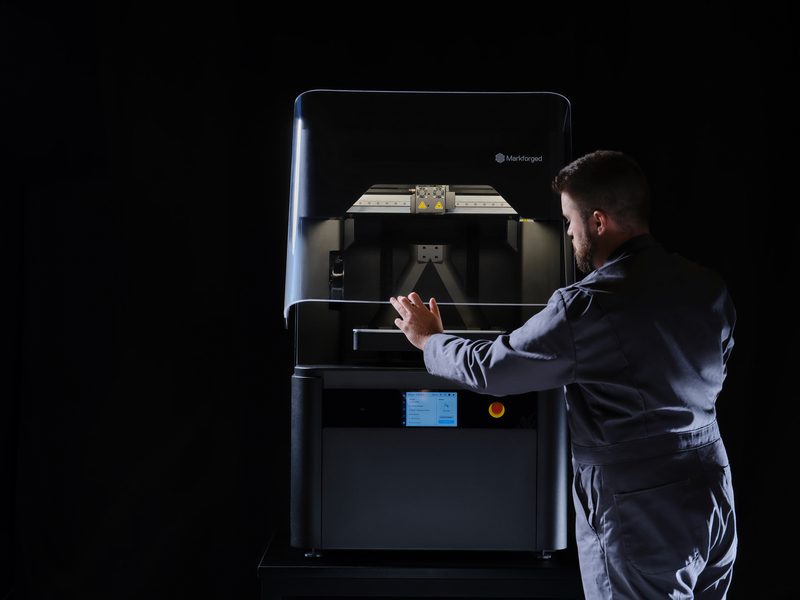

Automated and intuitive

Highly automated workflows make FX10 easy to use, enable higher productivity and require less operator intervention.

Automatic reel changing enables continuous printing. To make prints that require a large amount of material, multiple reels can be loaded before printing starts.

Automatic machine calibration and pre-press processes ensure consistent print quality that does not depend on the operator.

Download

Fill out the form