X7

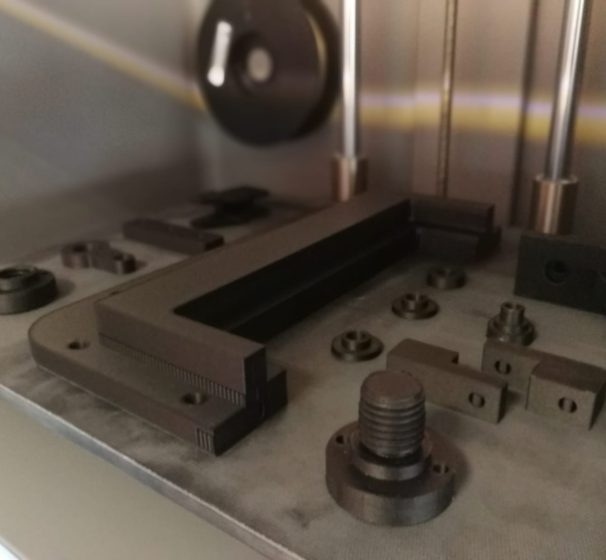

The only industrial 3D printing system for mechanical equipment capable of providing a measurement report

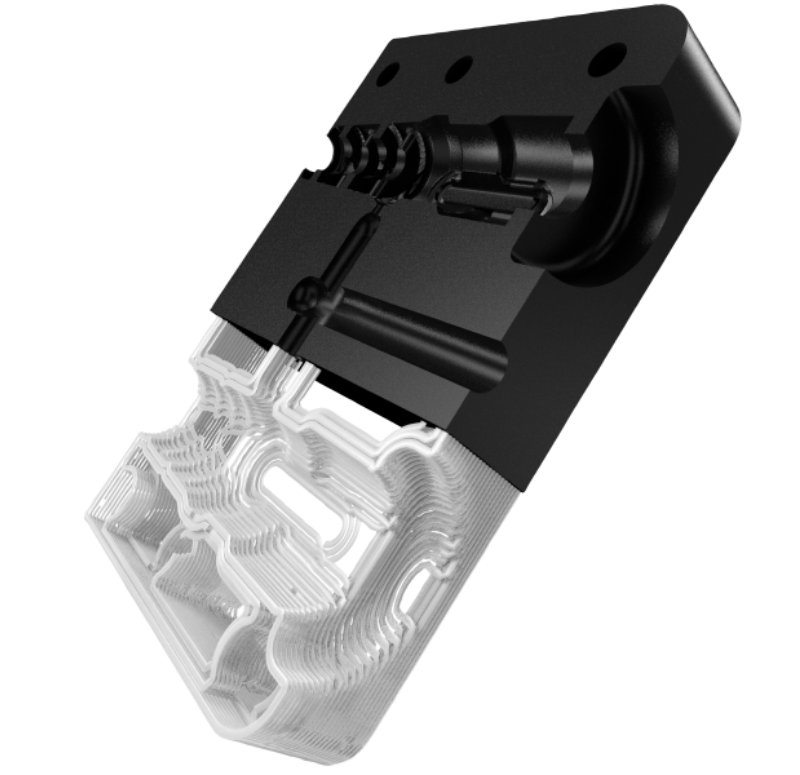

Built from the ground up for reliable performance, the X7 delivers breakthrough quality and precision in 3D printing. The top-of-the-line industrial grade platform features a strengthened dual nozzle print system that supports Continuous Carbon Fiber and Kevlar reinforcement. Laser inspection scans parts mid-print to ensure dimensional accuracy for the most critical tolerances.

- Print volume

- 330 mm x 270 mm x 200 mm

- Footprint

- 584 mm x 483 mm x 914 mm

- Z resolution

- 50 μm

- Technology

- FFF, CFF

Onyx

Nylon filled with carbon microfibre offers an excellent level of heat resistance, surface finish and chemical resistance.

Onyx FR

Flame-retardant nylon with V-0 UL 94 certification, filled with carbon microfibres, with the same basic properties as Onyx.

Onyx ESD

The strongest, most rigid and ESD-resistant Onyx variant for industrial and electronics manufacturing applications.

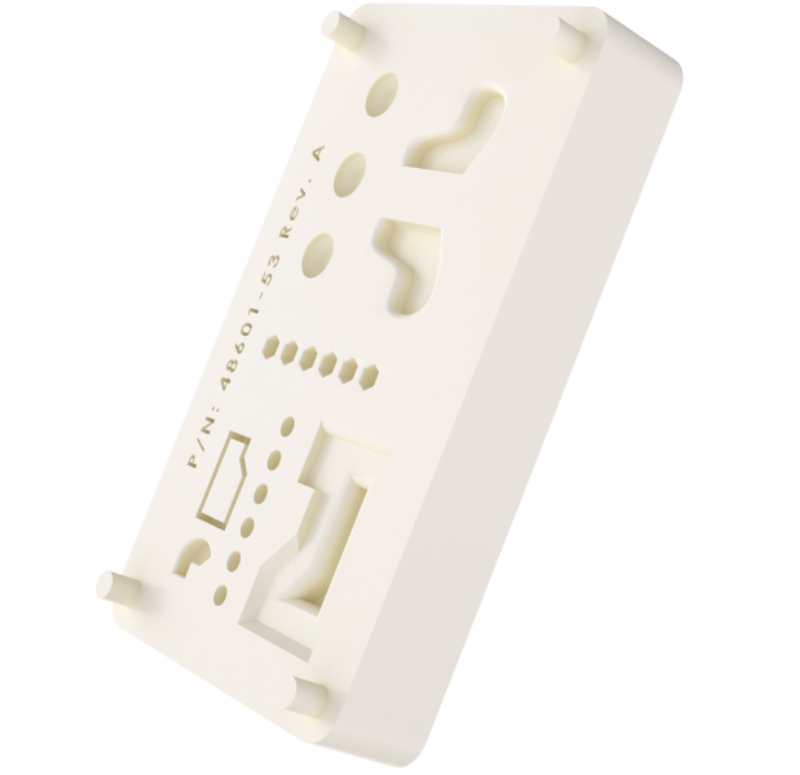

Nylon

Smooth, white, non-abrasive and easily paintable nylon thermoplastic, preferably used for non-scratch piece gripping systems and human contact.

Precise PLA

Cost-effective prototyping plastic, available in 8 different colours, designed to print reliably and accurately.

Carbon fibre

Rigid, strong and extremely light, carbon fibre reinforcement produces components that can replace machined aluminium.

Glass fibre

Inexpensive and 11 times stiffer than ABS, Glass Fibre is the ideal entry-level continuous fibre for 3D printing functional components.

Aramid fibre (Kevlar®)

Extremely durable and highly resistant to catastrophic failure, Kevlar® is an excellent reinforcement choice for harsh environments.

Glass fibre HSHT

In the range of our continuous fibres, HST Glass Fibre provides the highest resistance to impact and other temperatures, which also allows it to be used for low-temperature moulds.

Prototyping

Verify and optimise your design for a perfect product in every respect. 3D printing makes it possible to produce high-quality prototypes extremely quickly, easily and inexpensively, which are essential for experimenting with alternatives or verifying every functional, aesthetic and design aspect, avoiding delays and errors.

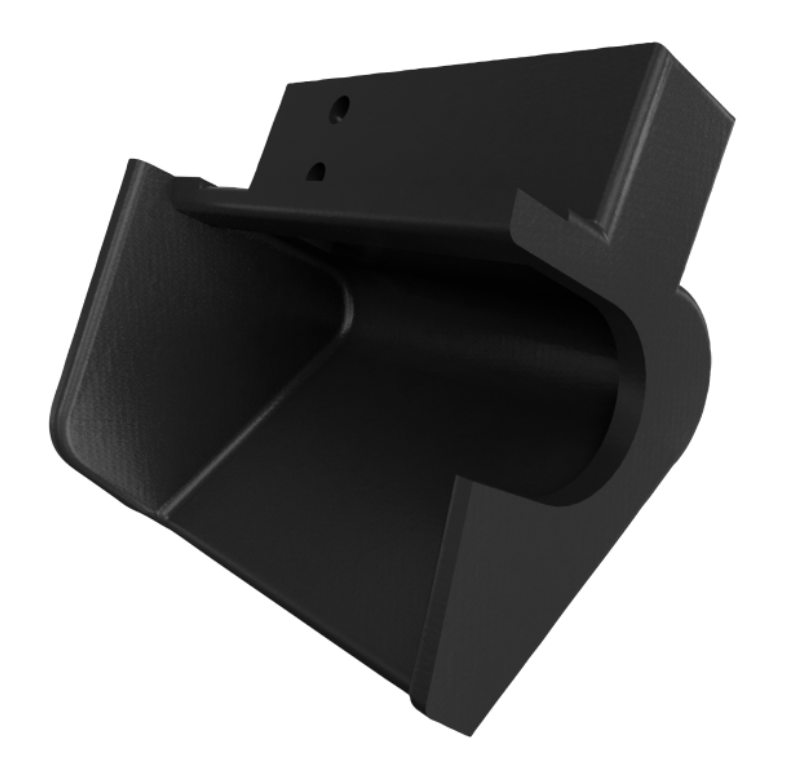

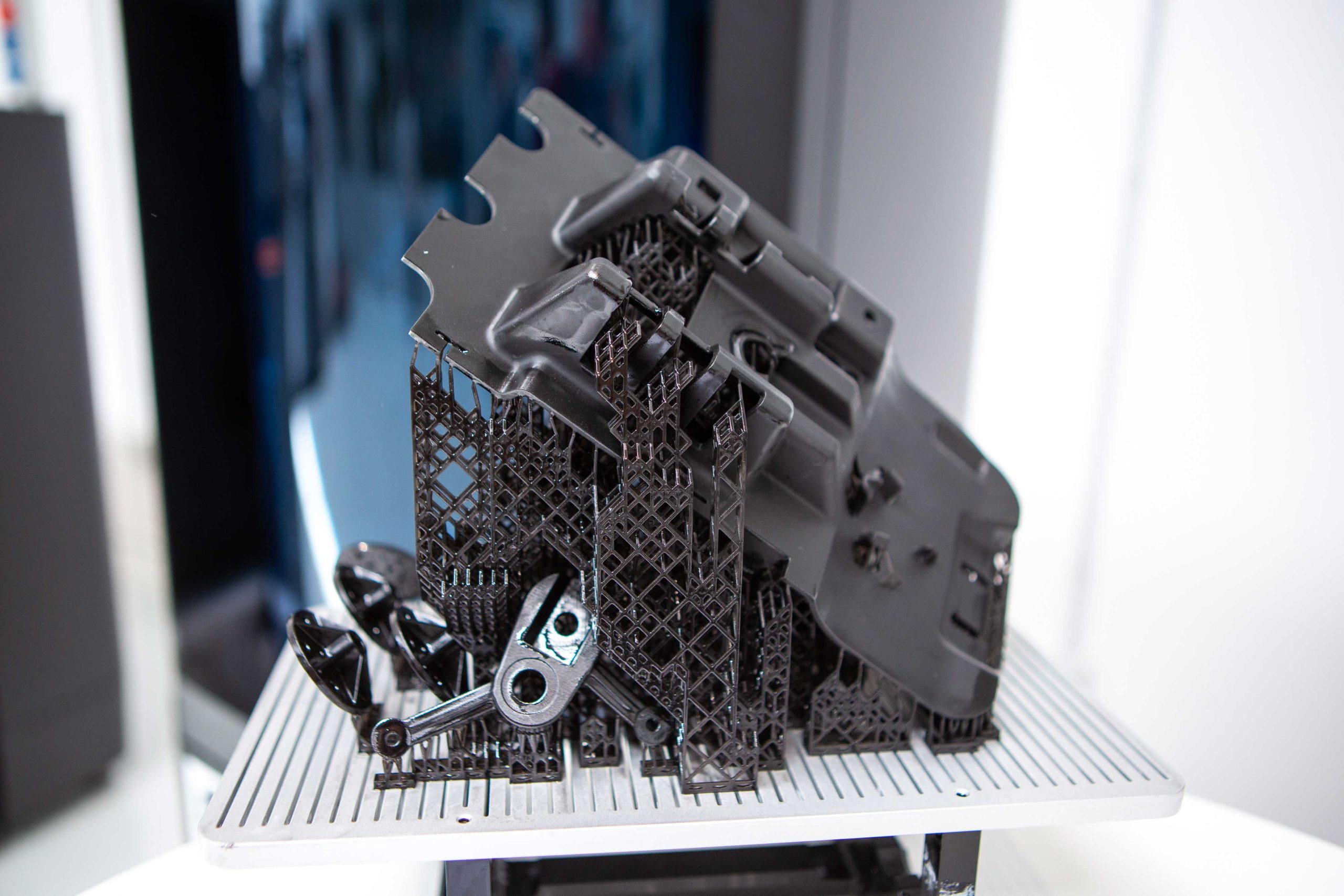

Tooling

Make everything you need quickly and in-house easily and inexpensively.

Thanks to 3D printing, the tooling of machine tools, the rapid production of parts, complete tools or tools required for production can be completely internalised, avoiding the costs of an external printing service and eliminating unproductive waiting times.

Production

Additive manufacturing aims to be the production of the future, whether for private use, independent businesses or industrial production. Improving industrial productivity through 3D printing and 3DZ offers a wide range of solutions to meet the needs of a variety of professional sectors.

Eiger

With automatic version control, automatic management of multiple printers and a cloud-based collaboration infrastructure, Eiger is the world’s most advanced 3D printing software.Designed to make production as simple as possible, Eiger allows you to print plastic, metal and composite materials directly from your browser.

The robustness you need for the production of tooling and functional parts. Designed for high accuracy and built to withstand the working environment, the X7 printer saves time and money.

20% stronger and 40% more rigid than ABS. You get parts resistant to impact and a wide variety of chemicals used in production. Manufactured parts withstand the toughest situations.

Designed to produce. Fully equipped with encoder motors and a laser micrometer. The X 7 is exceptionally accurate, reliable and has a high level of repeatability.

Download

Contact us to get more information and request a quote