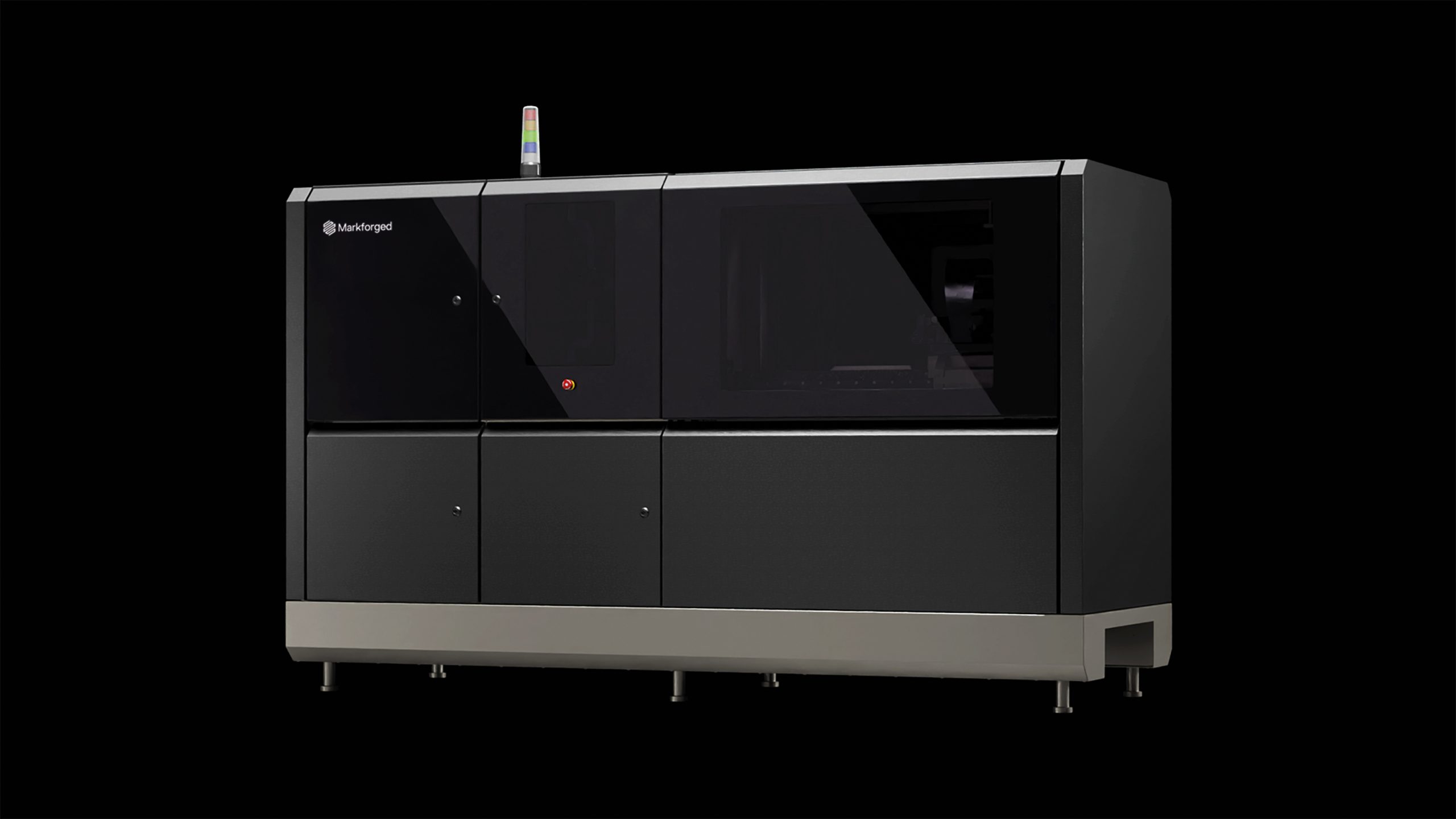

PX100™

The metal powder 3D printer for small batches

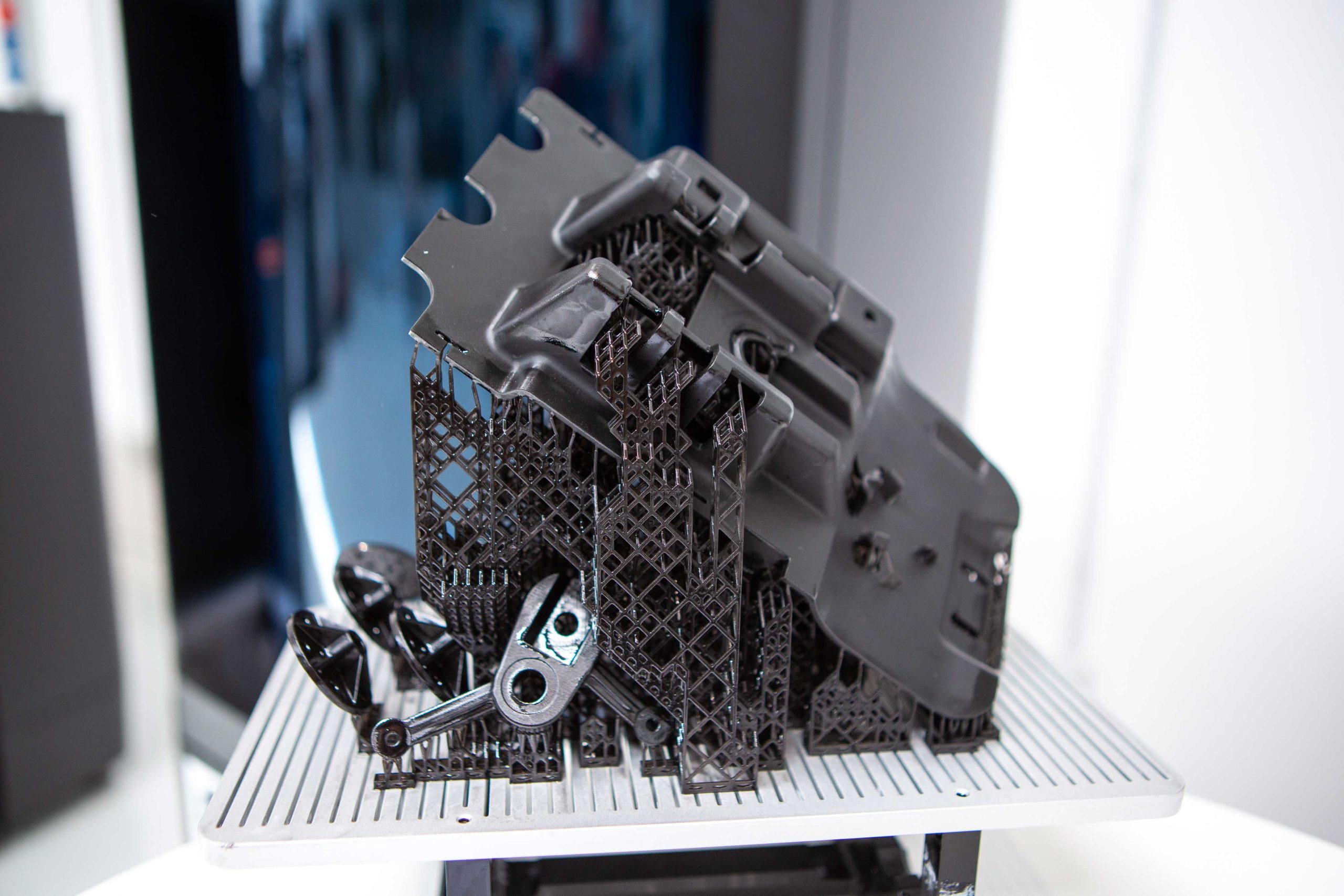

Complete metal 3D printing solution. 1. large working area 2. high density of parts, for mechanically stronger parts, more prone to heat treatment, with high degree of isotropy 3. surface roughness of parts less than 10 microns"

Markforged PX100™ - fast and accurate

𝗔𝗱𝗱𝗶𝘁𝗶𝘃𝗲 𝗺𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗶𝗻𝗴 𝘁𝗼 𝗺𝗲𝘁𝗮𝗹 𝘄𝗶𝘁𝗵 𝘂𝗻𝗽𝗮𝗿𝗮𝗹𝗹𝗲𝗹𝗲𝗱 𝗽𝗿𝗲𝗰𝗶𝘀𝗶𝗼𝗻

-Direct production with low waste production (waste material)

- Reliable accuracy

- Optimized powder utilization: nearly 100% of excess powder is recycled

- Print volume

- 250 × 217 × 186 mm

- Accuracy

- Static accuracy higher than 1 μm

- Print speed

- Up to 1000 cm3 per hour

- Extrusion/nozzles

- Printhead with 70,400 nozzles delivering 2pL droplets at 15.5 kHz

- Materials

- Rapid change of materials

- Machine design

- Robust to minimize downtime and unplanned shutdowns

Stainless steel 17-4PH

17-4PH is a martensitic stainless steel hardened by precipitation, known for its high strength, wear resistance, corrosion resistance and weldability. This versatile material has applications in various industries such as the oil, chemical and aerospace industries, where it is used to make heavy-duty machinery components heavy-duty, couplings, screws, drive shafts and nuts. 17-4PH can be heat treated to meet specific mechanical requirements.

Stainless steel 316L

316L is a low-carbon austenitic stainless steel known for its excellent ductility and corrosion resistance. It is a versatile material used in a variety of applications and industries including dental/medical, consumer electronics aerospace, maritime and designer textiles.

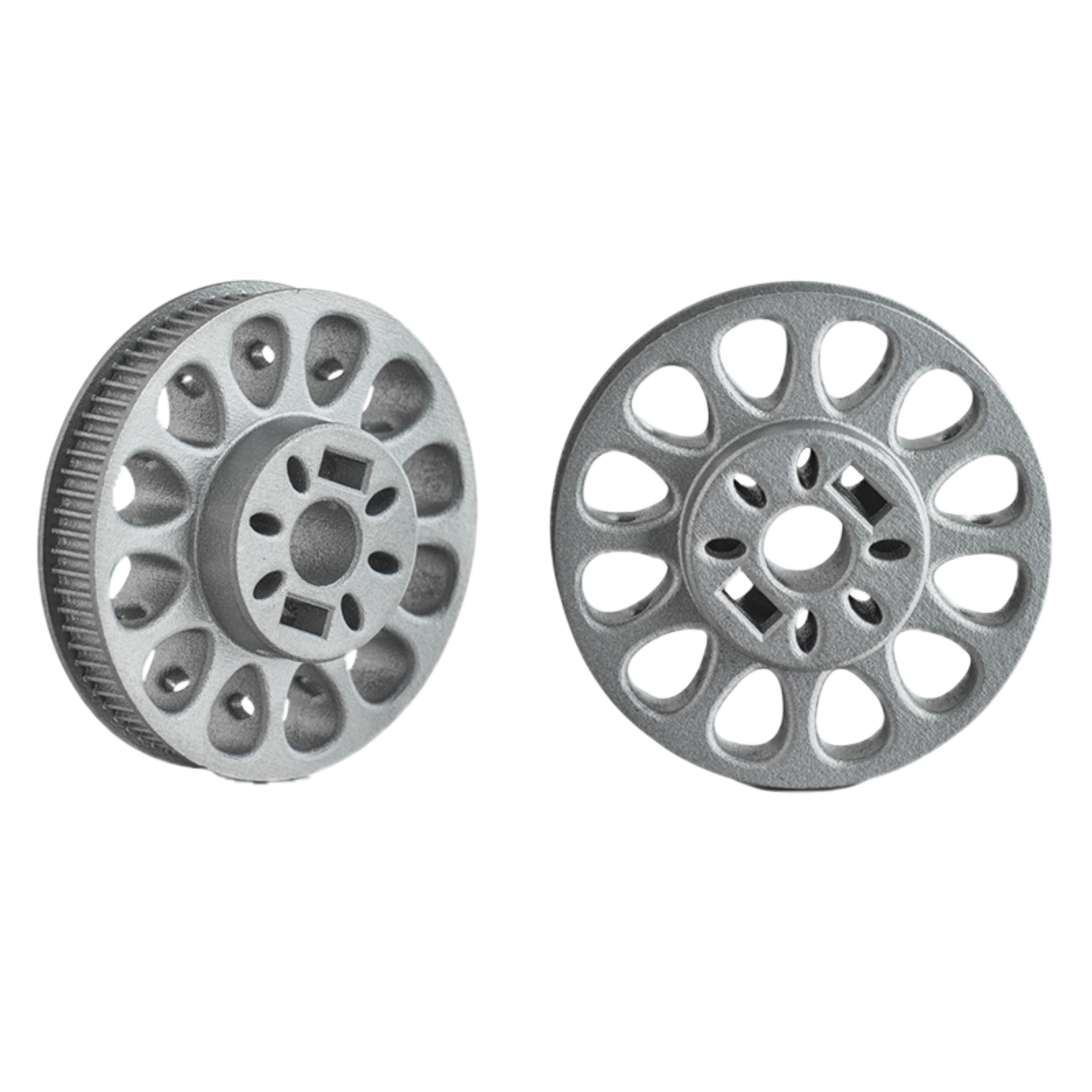

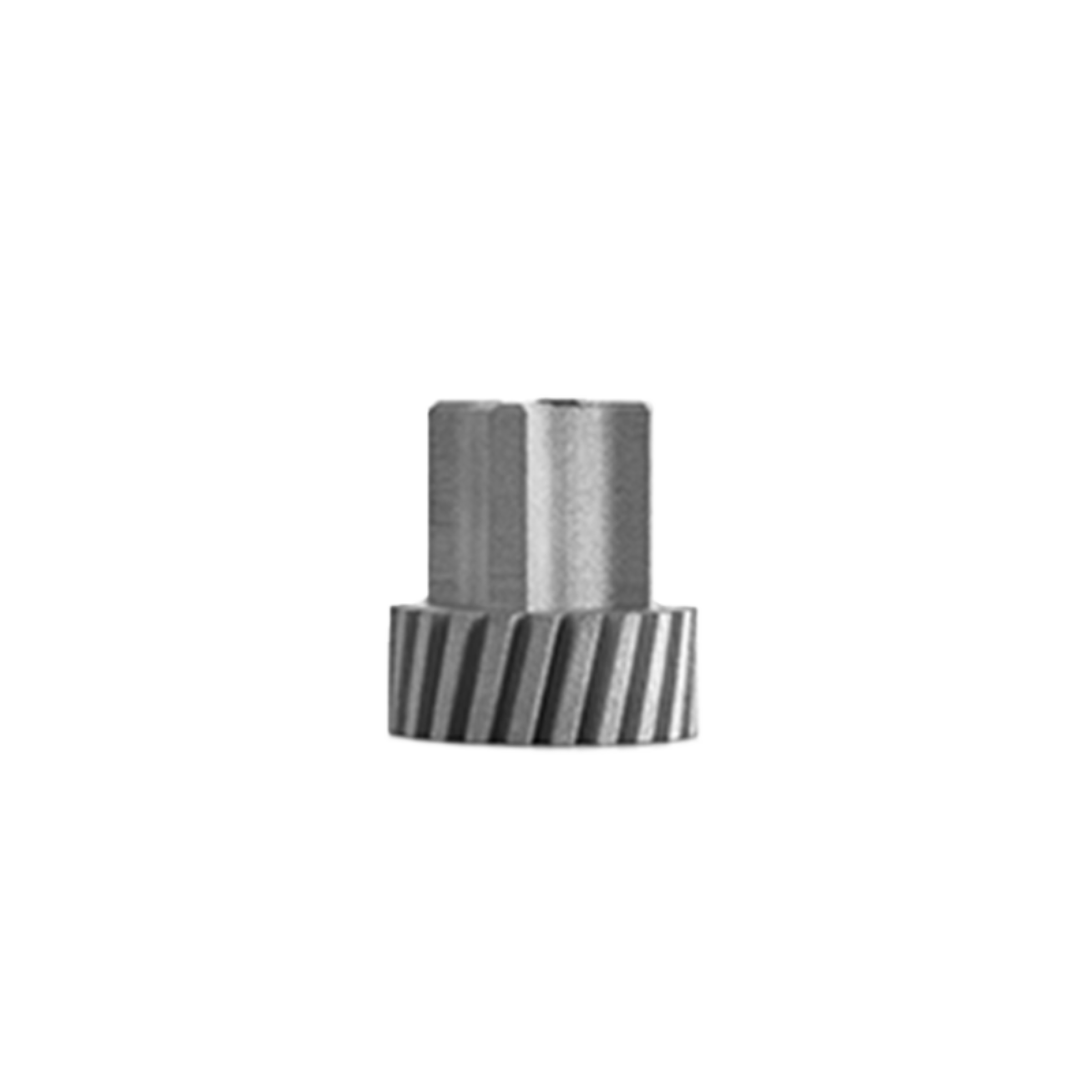

Steel 4140

4140 is a low-alloy steel known for its high strength, hardenability and toughness. It is commonly used to make gears, pulleys and fasteners in the automotive and machinery industries, where there is a need for components characterized by strength and precision. In addition, it can be machined and welded with ease, and can be heat treated to improve its mechanical properties.

Tooling steel H13

H13 is a high-performance steel used for machining hot machining of tools. It features excellent resistance to thermal fatigue, hardenability, wear resistance and toughness. È commonly used for hot and cold machining, but it is particularly suitable for hot applications because of its extraordinary properties.

H13 is harder and more abrasion resistant than most of mild and stainless steels, but is less hard than other tool steels such as D2. Its combination of properties makes it a versatile and reliable choice for a wide range of applications.

Tooling steel D2

D2 is an air-hardened tool steel that offers extraordinary hardness and abrasion resistance while maintaining a moderate toughness.

It is mainly used for cutting and forming tools, such as shears and cutters, punches, dies and tools for molding. This material remains stable during heat treatments, making it possible to refine the final properties after sintering.

League 247

M247 is a high-performance nickel-based superalloy with exceptional thermomechanical properties. The material is closely related to IN625 and IN718 and exhibits remarkable intrinsic oxidation resistance, as well as extraordinary strength and creep resistance at

elevated temperatures. It is particularly suitable for use in demanding applications

such as aerospace, gas turbine engines, systems combustion/exhaust systems, turbopump impellers and other environments similar characterized by high temperatures.

League 625

IN625 is a high-performance nickel-based superalloy known for its toughness and excellent corrosion resistance in both oxidizing and reducing environments. It is more resistant to corrosion and can be used at higher temperatures than IN718, but has lower mechanical properties. It lends itself well to a variety of demanding applications

within chemical processes, aerospace and marine engineering, power generation, and oil/gas. The material is notoriously difficult to process, making printing

3D a viable alternative.

League 718

IN718 is a high-performance nickel-based superalloy, equipped with excellent strength and good corrosion resistance at high temperatures.

It is stronger and harder than IN625, but has lower resistance to corrosion and a lower operating temperature threshold.

Alloys of IN718 are commonly used in aerospace applications: turbines, spacecraft, rocket engines, turbopumps and tooling.

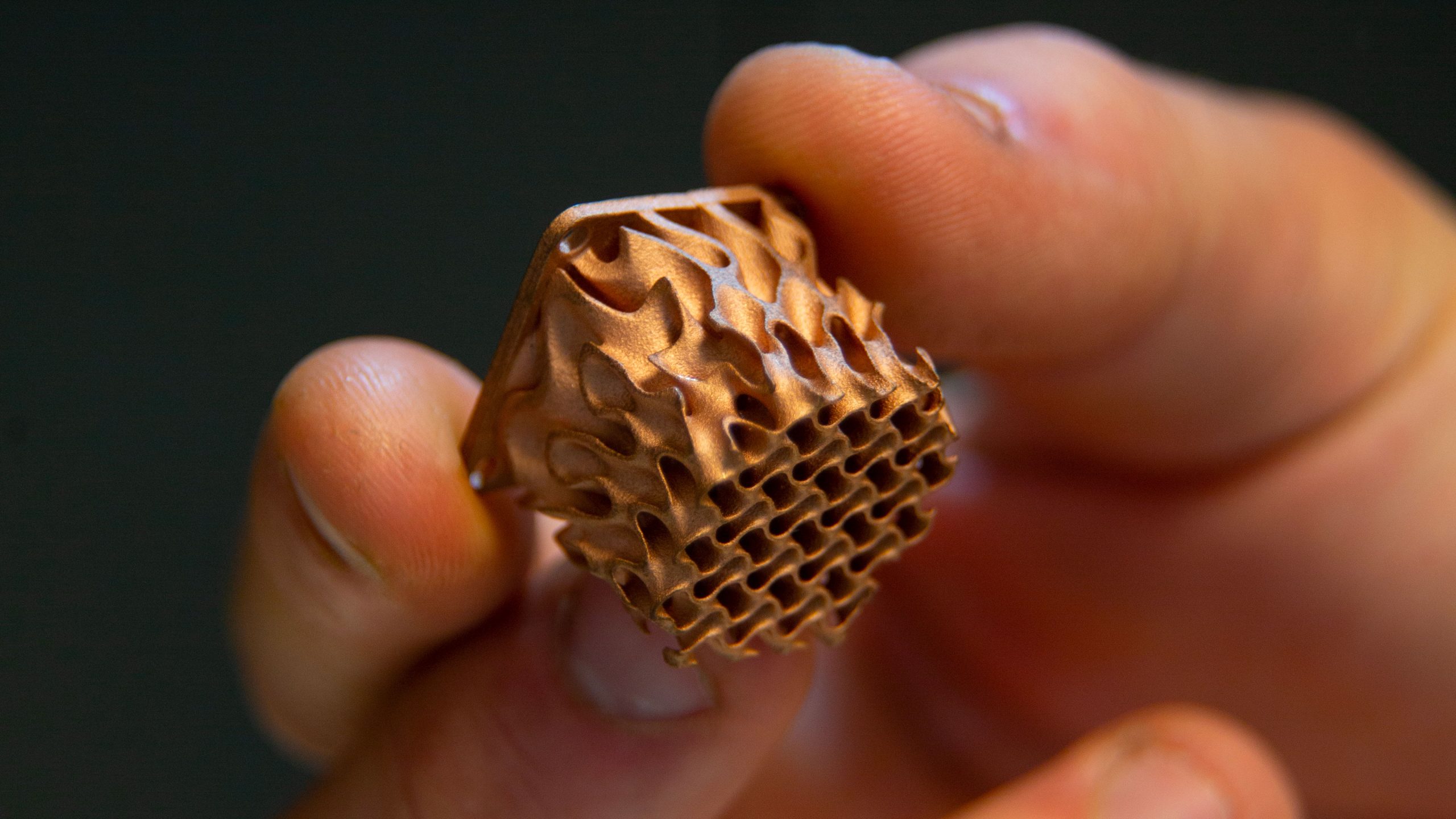

Copper

Copper is a 99.9% commercially pure material and is endowed with excellent electrical properties and thermal conductivity. It is mainly used for electronic components, heat exchangers, heat sinks, motor parts, as well as in a variety of industrial applications where a good conductivity.

Copper printing offers design freedom and allows for an optimal functionality with few limitations

Ti6Al4V

Ti-6Al-4V is a titanium alloy that combines high strength, hardness and ductility with high corrosion resistance. Its strength approaches that of steel while being 45% lighter

light, giving it one of the highest strength-to-weight ratios in production materials.

The most common applications are aerospace, but Ti-6Al-4V is also used in the marine, automotive, chemical, biomedical, and energy.

Prototyping

Verify and optimize your design to achieve a product that is perfect in every aspect. 3D printing enables extremely fast, easy and cost-effective production of high-quality prototypes, which are essential for experimenting with alternatives or verifying every functional, aesthetic and design aspect, avoiding slowdowns and errors.

Production

Additive manufacturing wants to propose itself as the production of the future, whether for private use, independent realities or industrial production. Improving industrial productivity through 3D printing and 3DZ offers a wide range of solutions capable of meeting the needs of a variety of professional sectors.

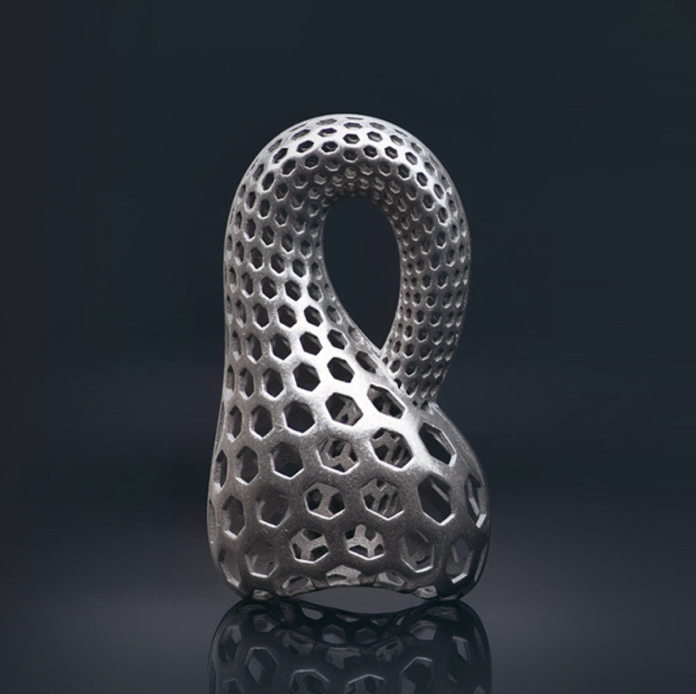

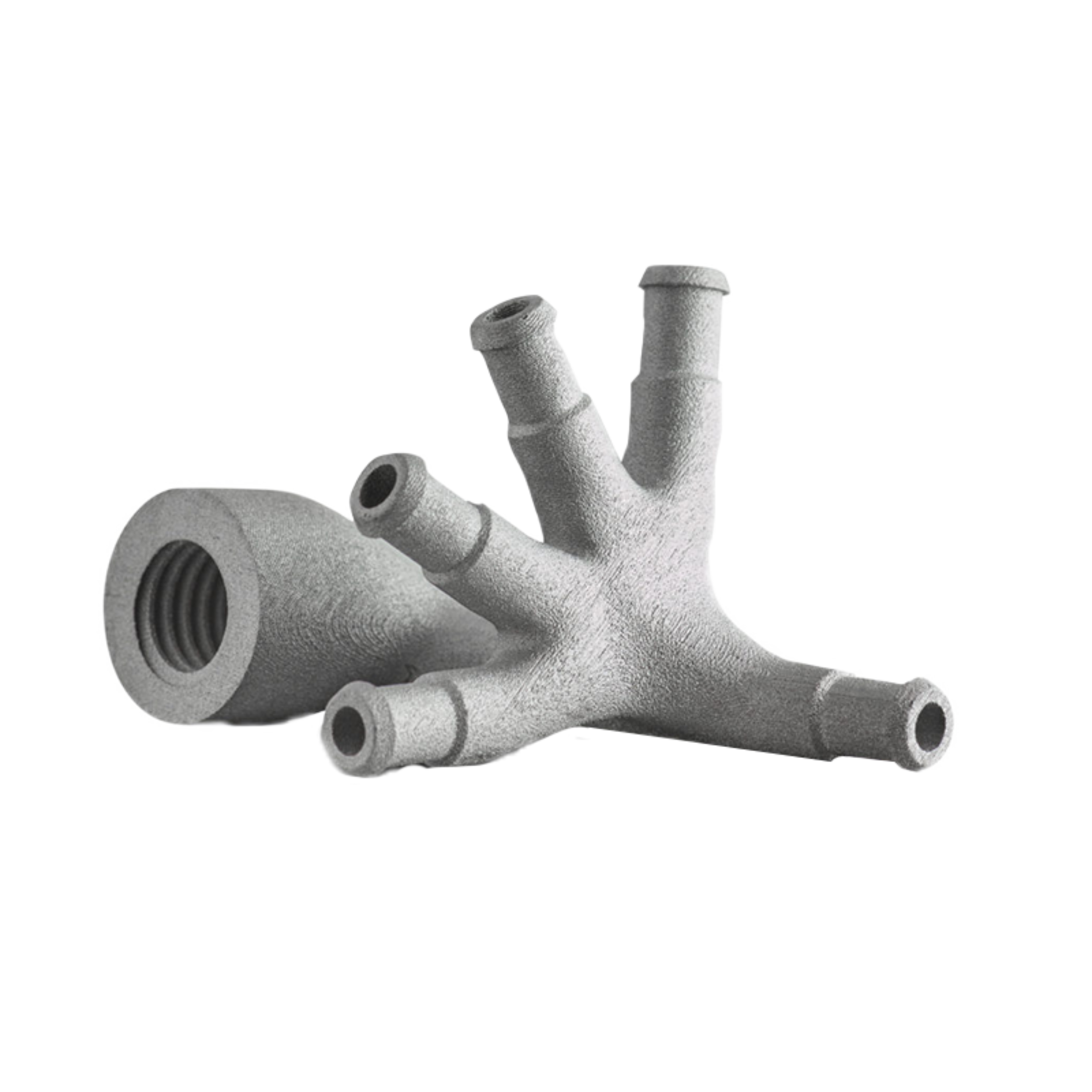

Design freedom

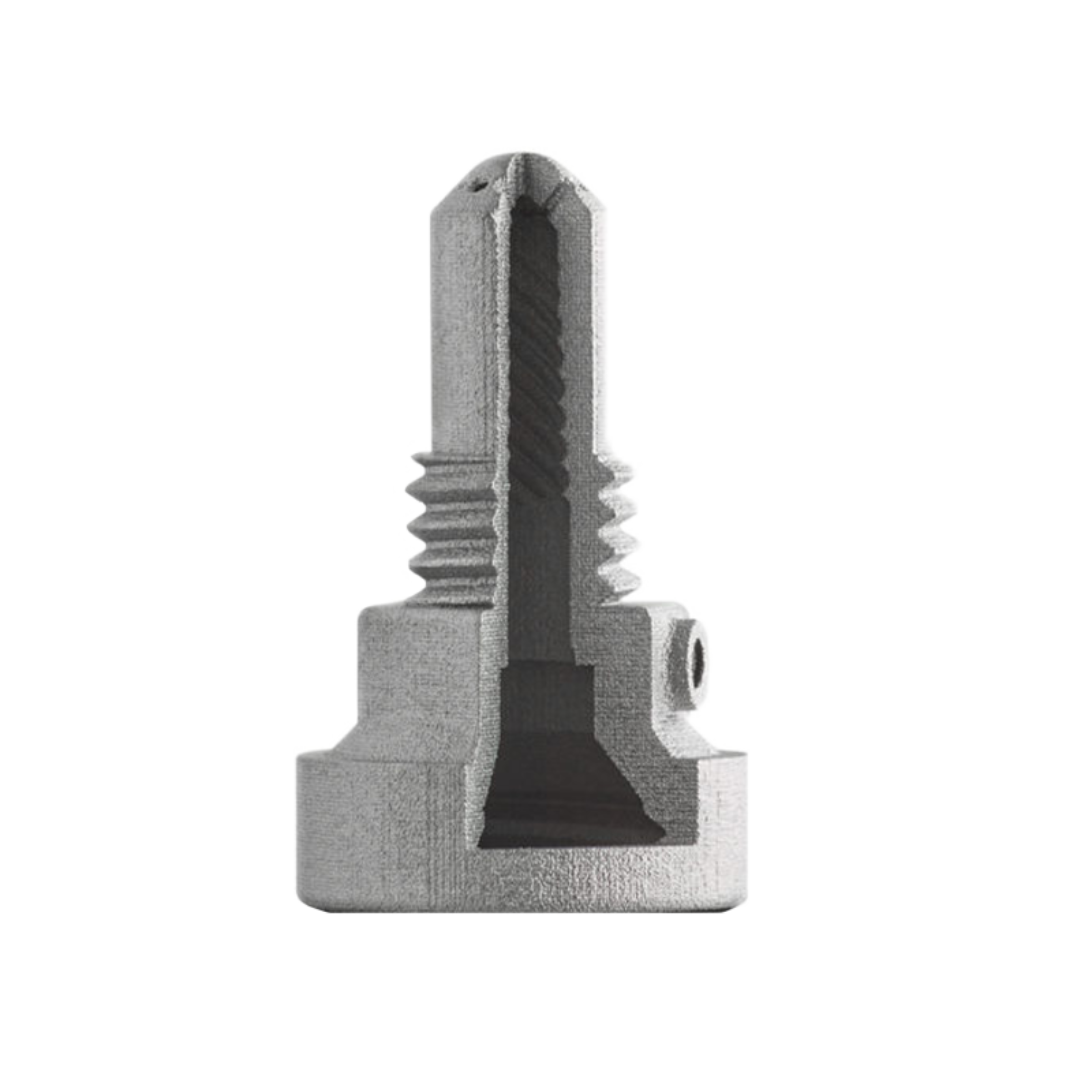

The PX100 is ideal for producing components with complex geometric structures, intricate internal details, and even integrated parts. With the precision of the PX100, it is possible to produce metal components that were previously difficult, or even impossible, to manufacture.

No support structures are required. This minimizes post-processing and increases productivity. Excess powder is almost 100% recycled! To produce large quantities of different or individual parts without complex tools and with minimal material consumption.

The drive system

Precision and speed have always been important.

To ensure long-term precision and accuracy, linear motors and air bearings are used instead of belt drives and screws. All moving parts have an accuracy of 1µm. This combination ensures excellent stability and repeatability. The applicator accurately applies uniform layers of powder, and the resolution is excellent: 8000 x 1600 DPI! The result is reliable and detailed parts, every time.

A complete metal 3D printing solution

The PX100 binder jetting system (3D Printing technology that uses a bed of powders, which are adhered by a binder deposited through an inkjet head) introduces a new feature: a manufacturing system capable of fabricating thousands of complex metal end parts.

The printer is a part of the PX100 system, which includes powder processing machines and furnaces to provide end-to-end manufacturing capabilities.

The system is highly configurable and features a wide range of materials.

The PX100 offers a cost-effective alternative to traditional manufacturing for small and complex projects in a variety of industries.

It enables the production of large volumes of metal parts at the time of need, offering companies the opportunity to exercise greater control over their manufacturing processes.

Eliminates the risks and costs associated with third-party suppliers by manufacturing parts in-house for critical production runs.

Download

Fill out the form