Magics 27

The best software for editing and repairing 3D files

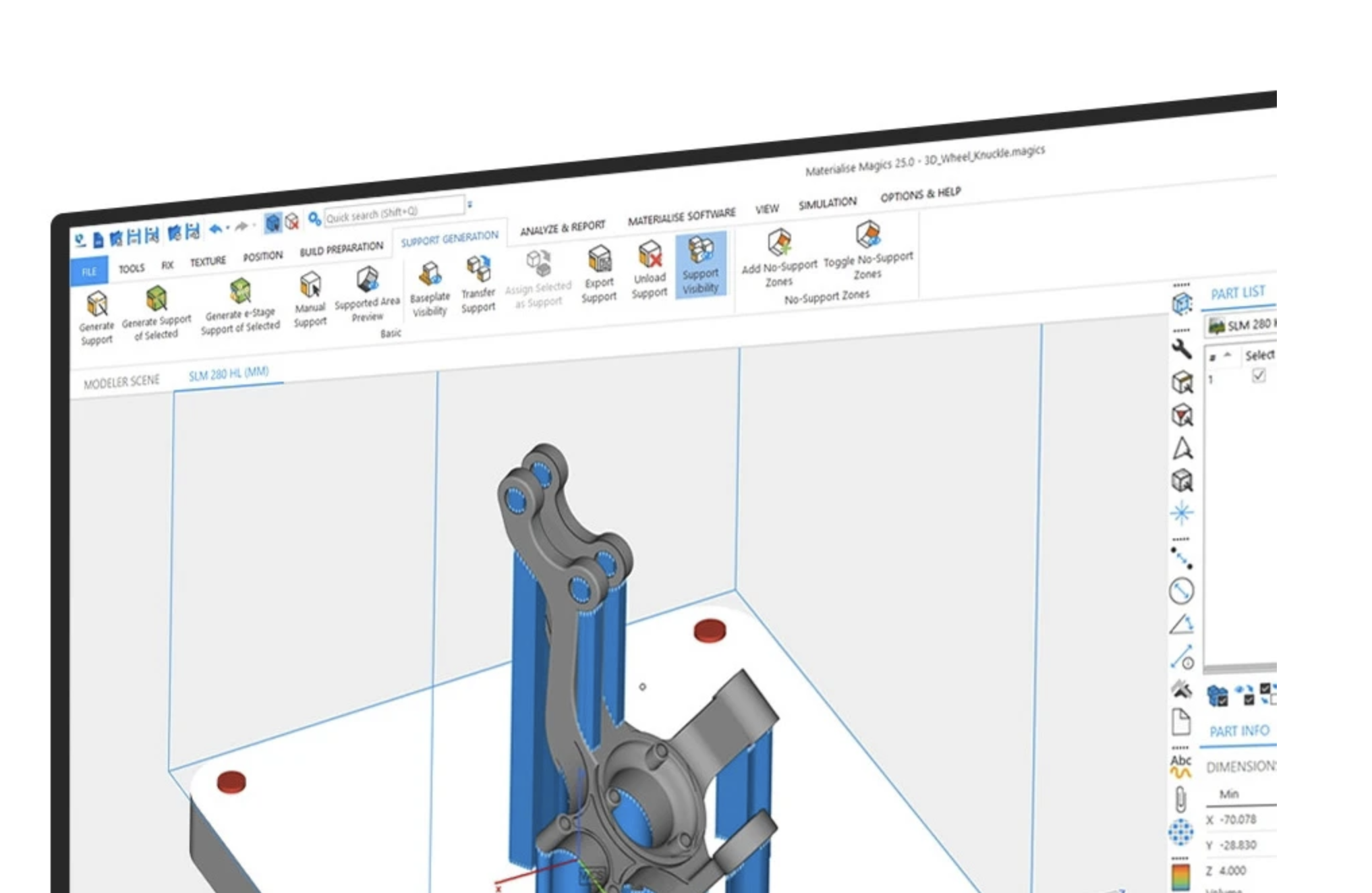

Materialise Magics is a smart and versatile software designed to prepare and elaborate STL files for 3D printing, provided with a user friendly and customizable interface. This state-of-the-art software of the industry will guide you efficiently in each phase of your job with additive manufacturing (AM). Some of the new characteristics of Materialise Magics 27 are: a refined transition passing through editing, fixing and the analysis of the parts both with CAD files and with mesh files, an improved and more versatile tree supports generation.

What's new in Magics 27

- Improved workflow with the ability to convert between parametric and mesh files.

- Improved drag & drop file opening in different work environments.

- Improved file preparation workflow with commands such as "measure distances" and "draft option."

- Simultaneous editing of several objects with build preparation commands and the ability to use customizable labels directly on part designs.

- Enhanced printer-program collaboration to improve print repeatability, part compliance with end-to-end data security with the integration of the new CO-AM.

Materialise Magics 27

Why Magics?

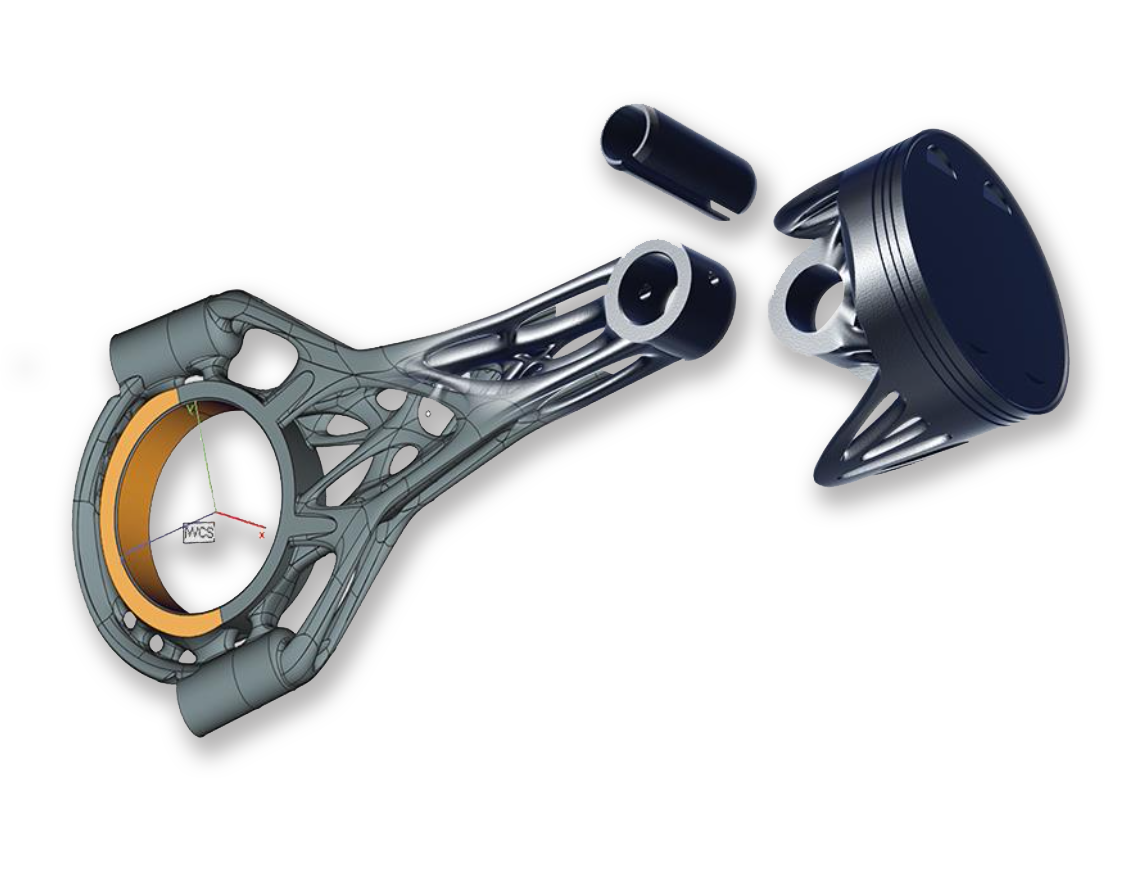

The best of CAD and mesh

Two is better than one. In magics 27 it is possible to take advantage of both the CAD tools and the mesh related ones for fluid and accurate production workflows.

Explore the tools of Magics 27

- Move easily from the modification to the repairing and to the analysis of the parts with CAD and mesh tools.

- Take advantage of the mesh tools in the work section of the platform to prepare your print.

- Generate tree supports quickly, improve the versatility and the performances to increase the printing success.

- Create simultaneous nesting of the components with supports that allow optimal nesting.

- Move quickly from the optimization software for the designing process to the file preparation and complete activities such as the improvement of the part quality, the creation of threads and adding punctures.

Magics 27, the updated version of the Materialise software for data and build preparation of 3D printing, has added to its existing mesh tools the option to support the workflow with native CAD files.

CAD offers a higher resolution in comparison to the mesh for the modification of the parts. However, the mesh offers a more coherent file format that grants the quality and compatibility with the 3D printers. Especially during the build preparation. The format of mesh files contains all the internal and external information necessary on 3D models to slice and start the 3D printing.

Magics 27 introduces a new Show/View of the part in which the users can modify parts in CAD formats, other than the Show/View of parts and builds in mesh for the modification, the saving, the analysis and preparation of the printing process. The users can choose the preferred workflow according to the characteristics of the 3D printing project and to modify the parts in mesh or CAD formats.

The new CAD workflow for the editing of the parts supports the users in their projects that require a strict coherence or a frequent exchange between the designing process and the data preparation process. The modification and saving of the parts in native CAD format allow the Magics users to maintain the integrity of the parts and to use better CAD files with high resolution.

This can help to reduce the time and iterations of the designing process and to improve the stability and repeatability of the process, avoiding errors that can occur switching from these types of files.

Magics will provide to you the right tools to import files, slice print jobs or any other in-between step.

Gain an extraordinary precision across the whole workflow by defining the best parameters for your print jobs.

Automate the processes with specialized modules that reduce the setting time and increase the production speed.

We offer one single software solution to satisfy your needs, regardless of any 3d printing technology and material you use/able to work alongside any…

Import almost any file format, maintain native information about colors and keep under control the original data.

Ensure that the parts are ready to be printed in high definition, with tools such as the automatic repair execution, offset and the generation of lattice structures.

Execute with precision operations such as slicing and the orientation and send the correct information to your machine.

Keep track of your prints and ensure the repeatability of the process with the automatic reports that need minimal human intervention.

Prepare the nesting with magics; enjoy higher speeds and an advanced control over the workflow.

Optimize the creation of support structures and reduce the time needed for the operation.

Avoid costly print failures by using the tools that detect potential print problems.

Contattaci per ottenere maggiori informazioni e richiedere un preventivo