Metal substitution and increased recyclability for on-demand manufacturing with 3D printing - Liebherr and Aitiip

Aitiip is a leading research and development center in Spain, serving companies in the aeronautics, automation, industrial and packaging sectors. The center is recognized for its constant search for transformative technologies.

In 2022, with the aim of exploring additive manufacturing and injection molding integrations to meet a challenge from its customer Liebherr, Aitiip contacts 3DZ.

The objective

Replace a metal impeller with a 100% recyclable high-performance polymer impeller, revolutionizing the injection molding process.

Liebherr, a leading German manufacturer of industrial equipment, represented by its aerospace branch in Toulouse, has collaborated with Aitiip to achieve a goal: to replace a metal impeller with an impeller made of 100% recyclable, injection-molded high-performance polymers.

The real ambition: to develop a technology that allows the manufacture of impellers for aeronautical cooling systems with 100% recyclable materials.

Two key aspects of the challenge have led Aitiip to turn to 3DZ: on the one hand, the performance of the chosen polymers, a fundamental part of the final quality, and on the other hand, maintaining profitability, since some characteristics of the parts would be more economical to produce by additive manufacturing.

Achieving recyclable PEEK material yield for a highly complex part

Complexity is a cost factor in most manufacturing processes, and manufacturers have looked to 3D printing as a way to simplify the production of objects with complex geometries. In the case of the impeller, design complexity was compounded by the ambition to replace metal with carbon-reinforced PEEK, a high-performance thermoplastic that was already very difficult to prototype.

Manufacturing parts in PEEK is not straightforward, as process parameters must be tightly controlled to achieve the desired performance. Liebherr worked with Aitiip, and Aitiip with 3DZ, to develop and verify a manufacturing process that met the following requirements:

➡ High-speed manufacturing process to reduce costs by 30%

➡ Use of recyclable materials

➡ Reduce weight by 40%

➡ One-shot manufacturing

FA and injection molding integration

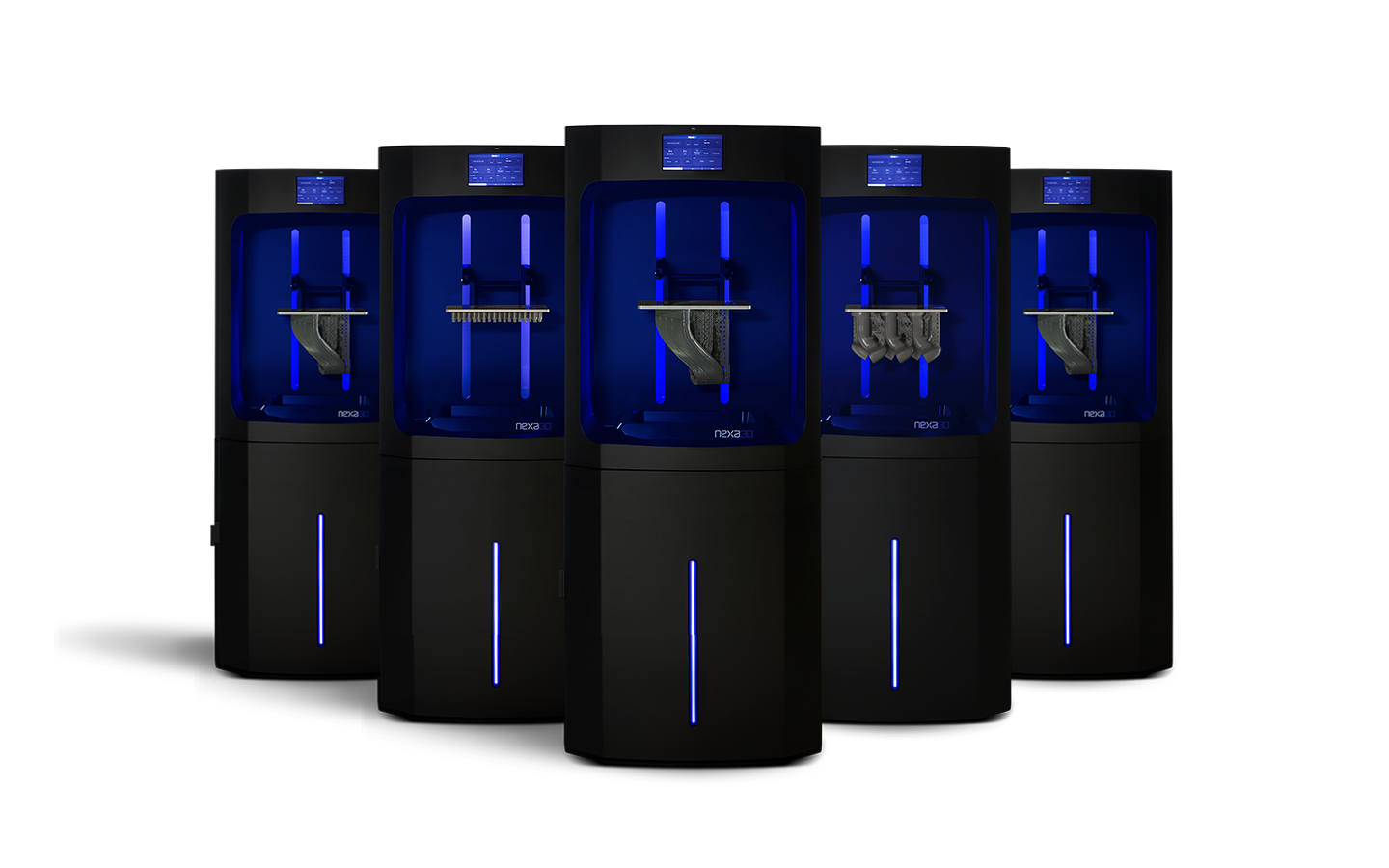

In 2022, Pablo Murillo, AITIIP Chief Business Development Officer, is in the process of renovating the center by refurbishing all the 3D machinery and adding transformative technologies to the center. In this context, it is Roger Sabaté, Sales Engineer at 3DZ Barcelona, who contacts him to offer our help. The fact that we have had a good relationship for years, makes Aitiip open the doors to start working. The objective is to find the most suitable solution for Liebherr together. The result of this search: the NXE 400 printer from Nexa 3D and the xMOLD and xPEEK resins for 3D printed tooling.

General advantages:

- Metal replacement

- On-demand spare parts due to low-volume injection molding

- No investment in metal tooling required for early performance verification

“The quality, repeatability and freedom offered by Nexa3D printers and xMOLD resin have allowed us to create and validate an entirely new on-demand manufacturing paradigm.”

3DZ CONSULTING + NEXA 3D TECHNOLOGY AND MATERIALS

The part to be manufactured was a complex impeller with a challenging load case. To achieve the required part throughput and manufacturing speed, injection molding was chosen as the manufacturing method. However, the complexity of the impeller would be impossible to achieve with conventional metal tooling.

To meet Liebherr’s requirements, Aitiip decided to fully exploit the capabilities of the NEXA 3D system with a very innovative approach:

-

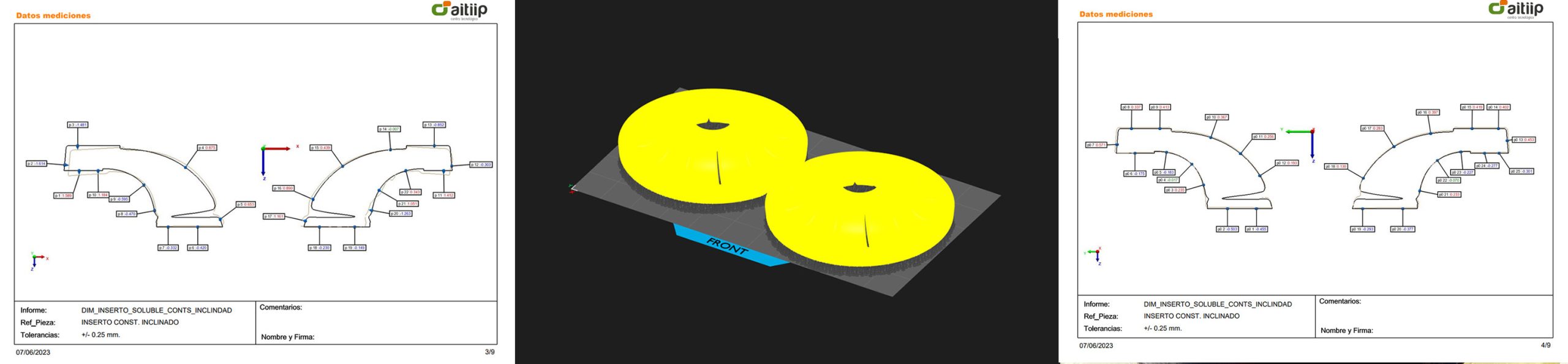

The inner geometry of the impeller body was realized with a single soluble Free Injection Molding (FIM) insert 3D printed in Nexa3D xMOLD printed tooling resin.

-

A very particular part of the part was made with an insert printed in Nexa3D’s xPEEK material. This insert is pre-assembled with the xMOLD FIM insert to ensure full integration into the impeller part during the injection molding process.

-

The assembly consisting of the 3D printed xMOLD FIM insert plus the xPEEK printed insert was mounted in a mold cavity. The carbon-reinforced PEEK material was then injected to fill the cavity and the 3D printed FIM insert was dissolved to release the final PEEK part.

“The consultative work was key throughout the process and, even today, on a day-to-day basis, as we maintain a very fluid and active communication. The fact that we have known each other for years has undoubtedly been something that has played in our favor when it came to the challenges. For their part, they were clear that they did not want subscription modalities and also that one of the critical points would be the choice of materials. The final proposal is a comprehensive turnkey solution that only 3DZ has the capacity to offer in Spain: Nexa 3D's ultra-fast 3D printers and xMOLD / xPEEK tooling resins.”

On-demand injection molding of a complex, qualified and tested impeller

Freeform Injection Molding (FIM), combined with xPEEK inserts, allowed Aitiip to fulfill the manufacturing of a high-performance recycled metal injection molded replacement part. In addition, Aitiip was able to verify part performance before having to invest in tooling.

What makes NEXA 3D's 3D technology unique

- It is one of the fastest for prototyping, pre-series and final part creation (up to 6.5 times faster than other 3D printers in the same category).

- It has a wide range of robust and high-performance materials, the Pro version is open source and compatible with various resins, such as xPEEK, xABS and xFLEX.

- Higher build volume than SLA and DLP technologies

- Next-generation software and predictive service

Solution benefits

The use of 3D printed xMOLD resin tooling allowed Aitiip to fabricate a series of test parts and use them to verify key aspects of design and performance.

FIM has enabled Aitiip to perform weekly iterations, consequently reducing project time and achieving better and more advanced results compared to traditional mold manufacturing processes.

In addition, the cost of research has been drastically reduced, making the use of resources (time, cost, material and, most importantly, human resources) more efficient while increasing design freedom.

The first iterations during the study phase were carried out on smaller 3D printed molds to ensure the shortest possible iterations with the lowest possible costs. Once the part design was validated and its performance verified, Aitiip proceeded to implement a unique metal cavity to accommodate possible internal modifications while still using a 3D printed xMOLD core and xPEEK insert. The resulting mold concept meets the customer’s requirements while containing the lowest possible cost of ownership and leaving the door open to customization.

The ability to quickly and cost-effectively test various tooling concepts was a key element in the ultimate success of the project. The complex part design, combined with the complex processing of carbon-additivated PEEK, and with the added challenge of integrating a 3D printed xPEEK insert into an injection molded part, would have made this project very difficult and costly to accomplish with conventional metal tooling: each iteration involves new investment and time, which, in turn, means a time lag in the project’s completion.

Metal substitution, increased recyclability

Aerospace parts manufacturers face stringent part quality requirements, and weight savings is always a goal. In addition, manufacturers are looking for ways to increase the application of end-of-life recyclable materials.

Liebherr wanted to explore a lighter alternative to the metal used in the manufacture of a high-performance polymer impeller, and collaborated with Aitiip to develop and verify a part design and manufacturing process that would allow Liebherr to migrate from metal to recyclable polymer.

Upon successful completion of this project, Aitiip provided Liebherr with the following key deliverables:

- A verified protocol for the manufacture of a specific spare part that enables Liebherr to reduce costs, lead times and supply chain vulnerabilities.

- A benchmark study demonstrating the performance achievable with new 3D printed injection molding tooling concepts and new resins for 3D printers.

- A reference model for high-variety, low-volume product development, scale-up and after-sales service based on an on-demand manufacturing platform as an alternative to stock supply chain paradigms.

The future

To talk about the future of Aitiip is to talk about “now” because in their constant search for innovation and new technological solutions, they have also acquired the Fuse 1+ 30w Selective Laser Sintering (SLS) printer from Formlabs.

With Fuse 1+ 30W, they will be able to produce high-performance functional parts in hours instead of days. In addition, the new nitrogen tank option creates an inert gas environment during the printing process and removes unwanted oxygen from the sintering environment making parts less brittle and more ductile. This results in better end-use parts, especially for industries where robustness is critical, such as automotive and aerospace.

They tell it to you in first person

Idioma 🇬🇧

3DZ, your expert partner

At 3DZ we are distributors of the best brands of printers of different technologies: this allows us to offer companies support in choosing the solution that really suits their needs. Do you want to share your needs with one of our 3D printing experts?

Contact us to make an appointment.