The UK's largest water service provider relies on Artec Eva ™ 3D scanning for use in its research and development departments to validate the non-demolition pipeline verification process.

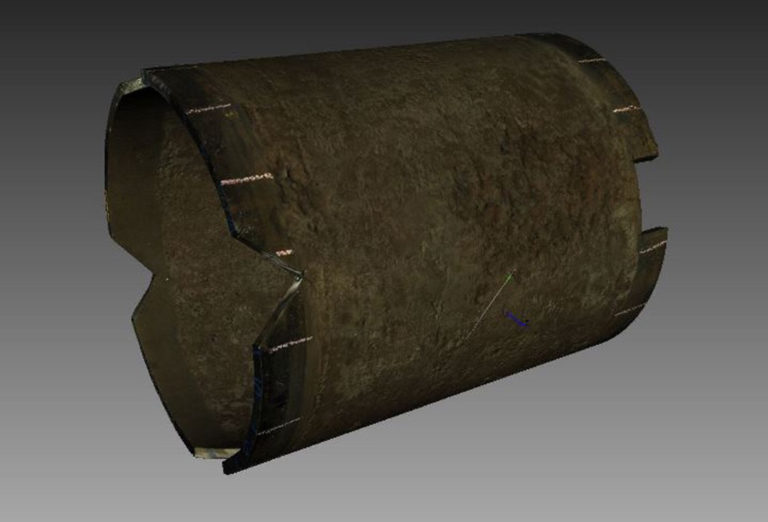

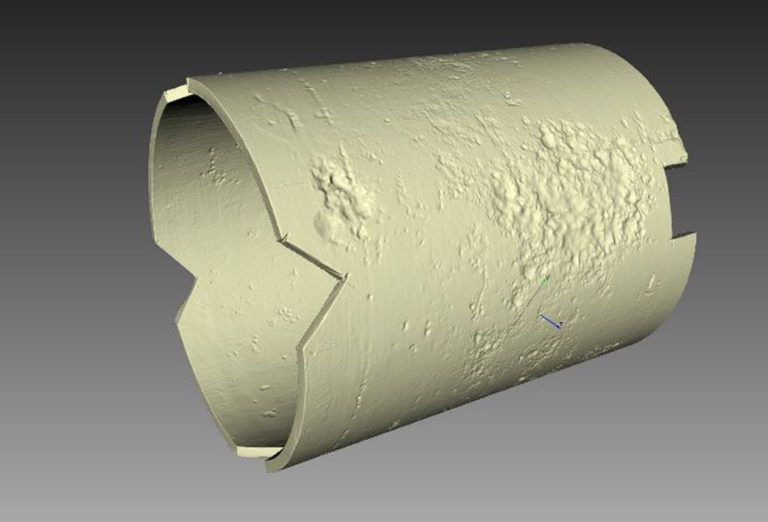

The goal: 3D scan selected segments of large diameter water pipes to create precise 3D models and use them to determine variations in the thickness of the surface wall of the pipe.

Thames Water is the UK’s largest provider of water and wastewater services, serving over 15 million users. One of its tasks is to provide its users with approximately 2,600 million liters of drinking water every day. In many areas of London, Thames Water’s cast iron pipelines are among the oldest in the UK, and many of them are starting to deteriorate.

For the past 15 years, the staff has been involved in replacing minor distribution pipelines, but now the main branch of the aqueduct is starting to cause concern. A single leak in one of the main pipelines would leave millions of customers without water, causing flooding and interruptions to transport routes.

Use of innovative techniques to verify the condition of the oldest pipes in the United Kingdom

Dr Tim Evans, water network innovation manager, explains how new technologies are paving the way for a more sustainable substitution approach. “Replacing pipelines is expensive, so we need to prioritize those most at risk,” he says.

“One of the big challenges with cast iron is that it doesn’t corrode evenly, and it’s difficult to identify the most damaged spots. With traditional techniques, the conditions of a water pipe are verified by cutting a portion of it. Then sand is sanded, to proceed with the removal of the corroded part, and the damage is measured manually. But cutting the pipes is a demolition operation that causes inconvenience to customers and motorists, and expensive for Thames Water. ”

To eliminate the need for pipe cutting, Thames Water has started using Non Destructive Technology, such as ultrasound. “It is similar to obstetric ultrasound, except for the fact that we are looking for corrosion instead of a fetus!” says Dr. Evans.

Surface scanners help Thames Water understand which tools are suitable for measurements with non-invasive techniques. A hand scanner is required for the main pipelines, larger than 45cm in diameter, and Thames Water approached various suppliers to evaluate their offerings and have the product shown. Artec Eva ™ performed these basic operations without problems. After scanning an important section of a pipeline, Thames Water came to the conclusion that Eva would be the best cost option for business needs. After the purchase of Eva ™, Artec assisted the staff by training them in the use of the system. Thames Water has also purchased additional software through which it is possible to perform a more in-depth analysis of Eva ™ data.

Artec 3D scanning software

Artec Studio 14, the recently updated software system, has increased the robustness of the mesh construction, with improved texture tracking during data logging. It also makes greater use of the multi-core capacity of the PC station, in order to complete the process in a much shorter time.

By comparing the pipe models before and after the removal of the corroded parts, it is possible to make an accurate mapping of the corrosion levels. This mapping, obtained thanks to the use of Eva ™, will be used by Thames Water as a reference to determine the effectiveness of the various non-demolishing intervention approaches.