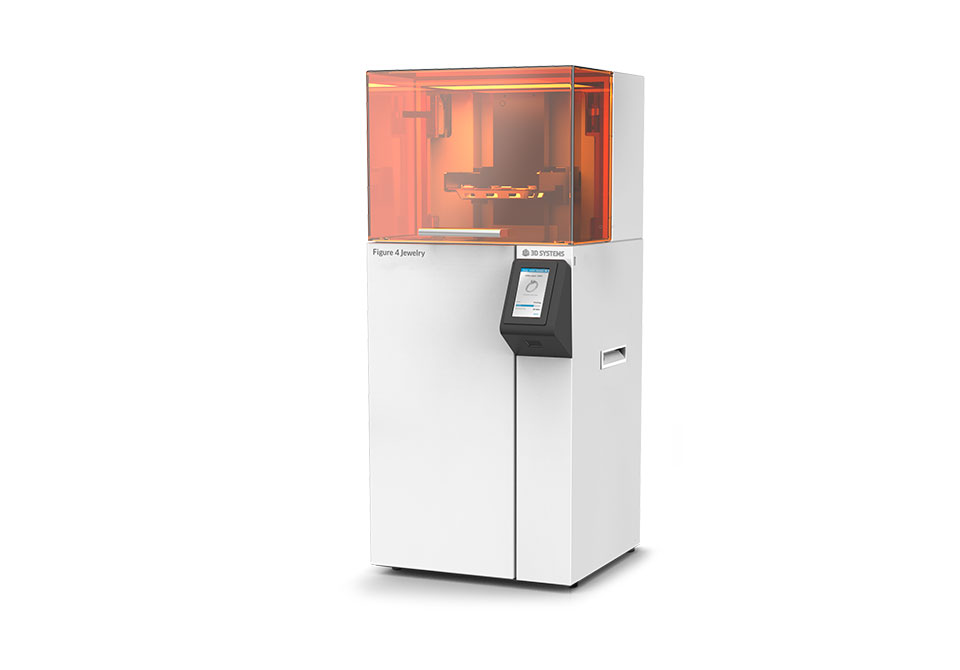

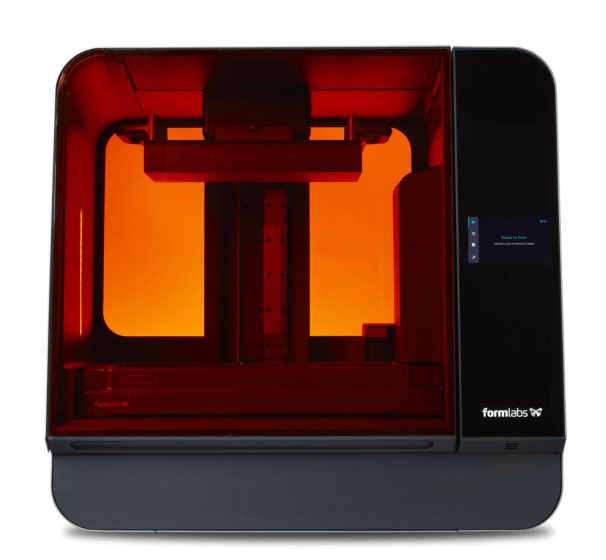

Figure 4 Jewelry

The fastest and most accurate resin 3D printer for jewellery making

Ultra-fast and reliable 3D printing solution created for digital flow jewelry design Part of 3D Systems Figure 4’s fully integrated, scalable technology platform, Figure 4 Jewelry is a cost-effective solution optimized for jewelry design and production workflows, offering unparalleled speed, productivity, ultra-fine detailing and smooth surface finish. Figure 4 Jewelry uses high precision, fine detail, speed and smooth surface finish. Optimized printing system, thanks to 3D Sprint® software. In addition, specially developed materials enable the development of three jewelry production workflows:

- Print volume

- 124,8 x 70,2 x 196 mm

- Print speed

- 16 mm/h

- Layer thickness

- 30μ

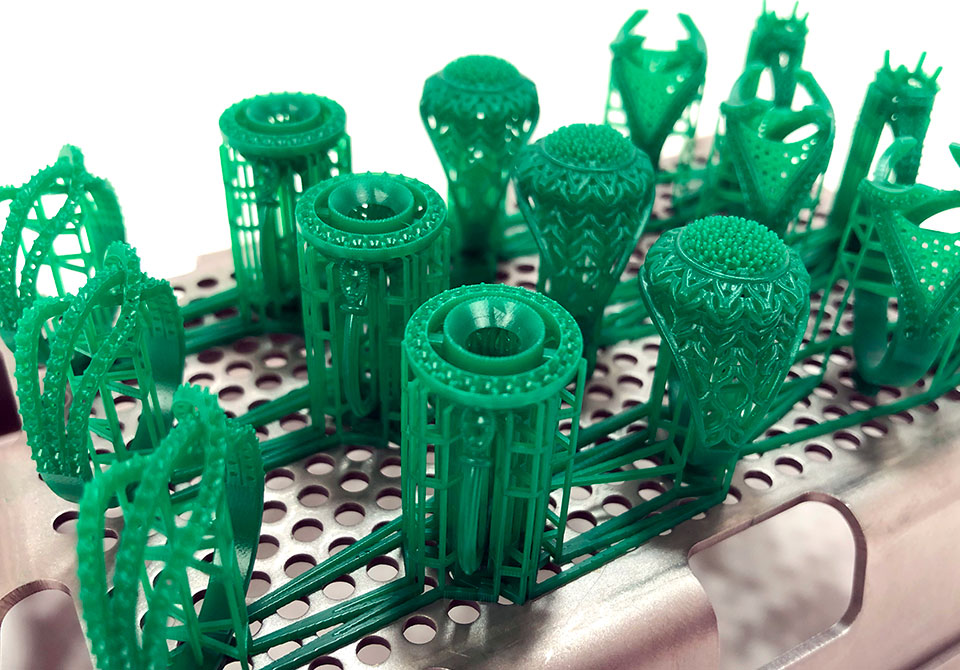

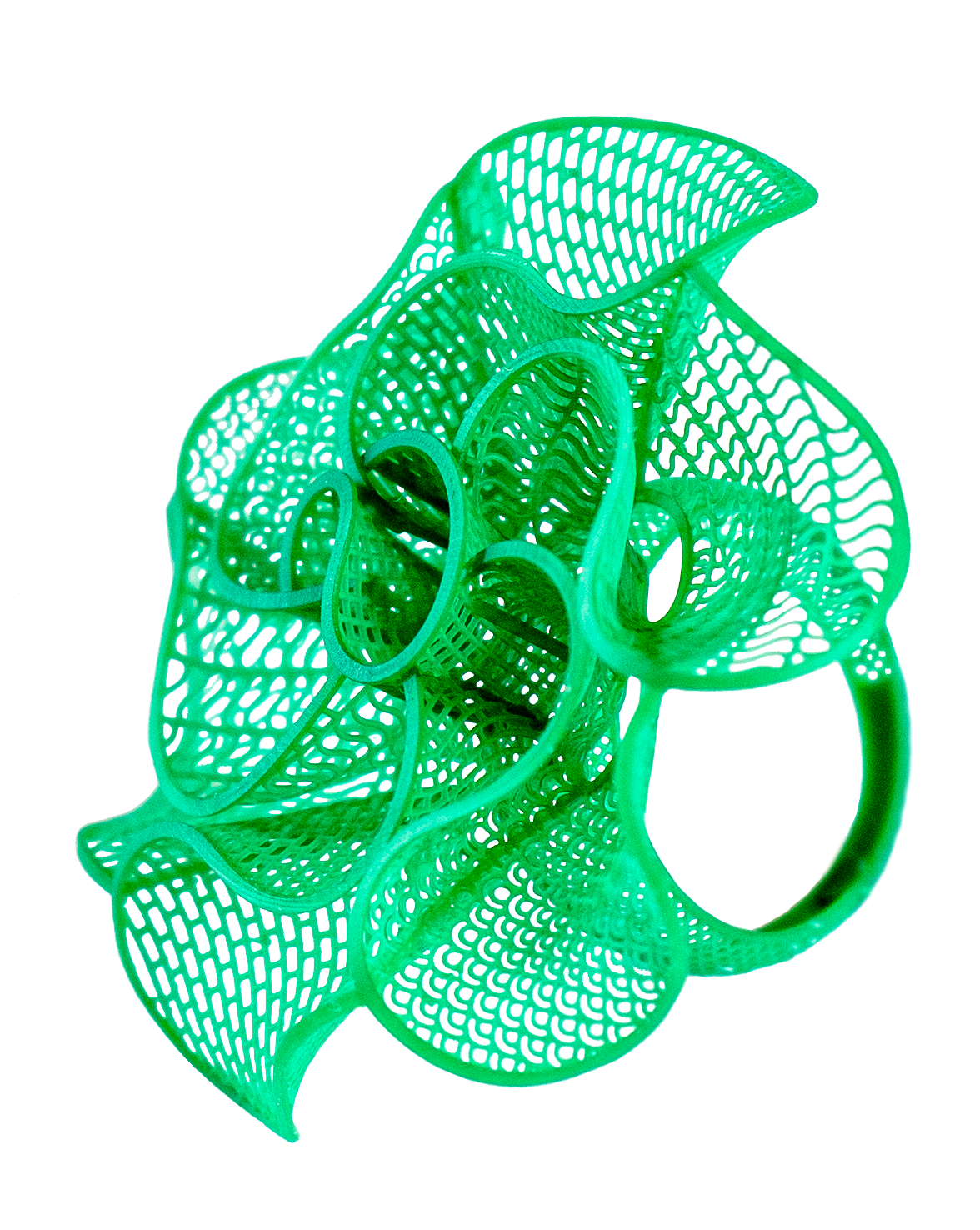

Figure 4 JCAST-GRN 10

Meltable jewellery application material for high-resolution models

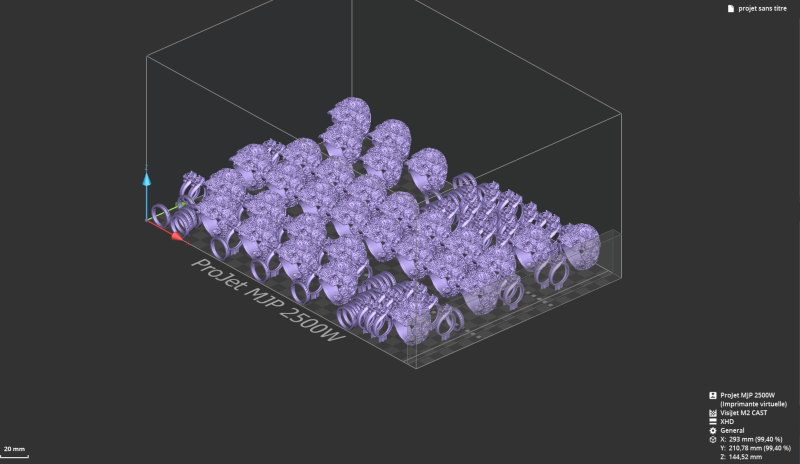

Figure 4 JCAST-GRN 20

For detailed, high-resolution jewellery models, direct casting with easy, clean burnout.

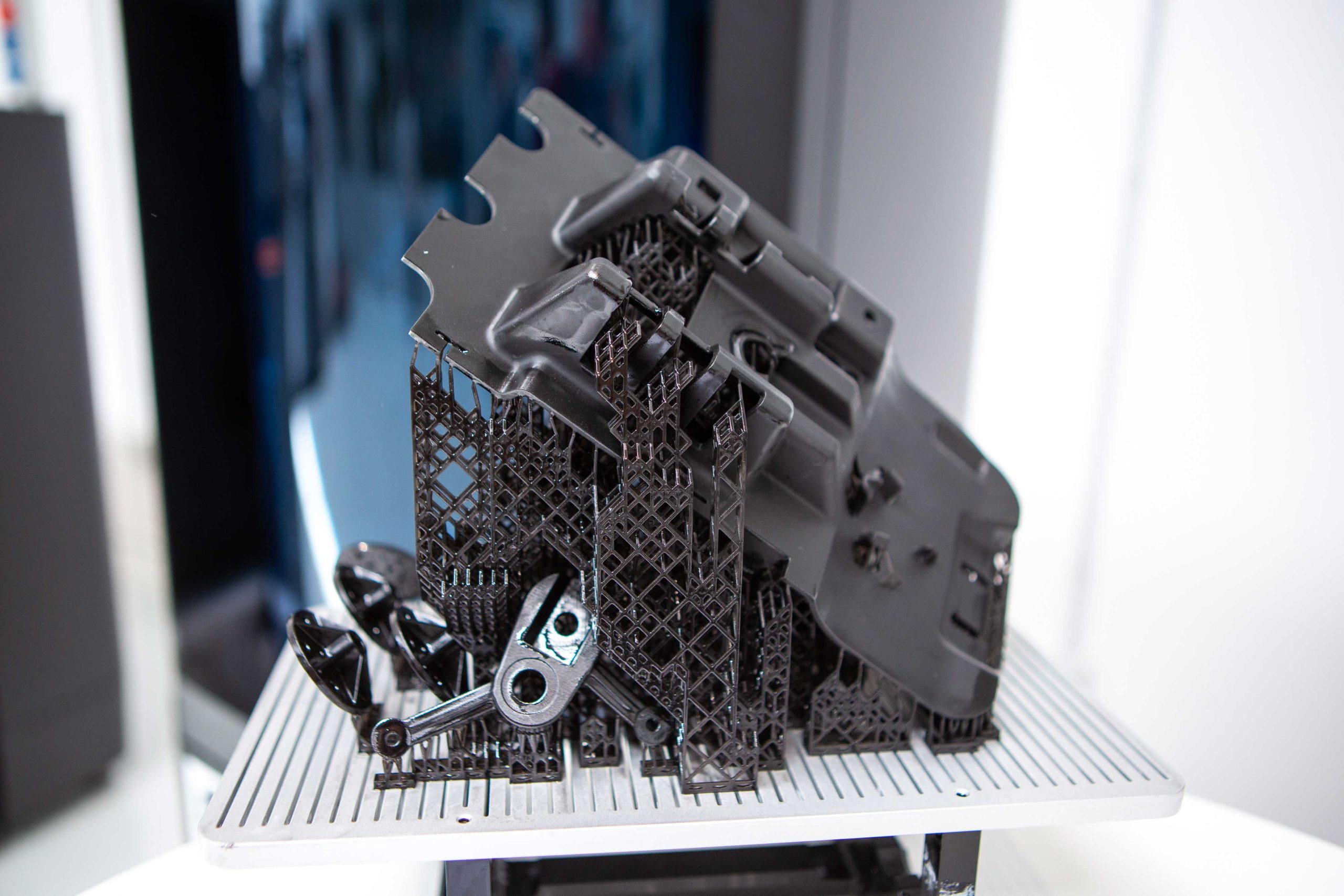

Prototyping

Verify and optimise your design for a perfect product in every respect. 3D printing makes it possible to produce high-quality prototypes extremely quickly, easily and inexpensively, which are essential for experimenting with alternatives or verifying every functional, aesthetic and design aspect, avoiding delays and errors.

Production

Additive manufacturing aims to be the production of the future, whether for private use, independent businesses or industrial production. Improving industrial productivity through 3D printing and 3DZ offers a wide range of solutions to meet the needs of a variety of professional sectors.

LC-3DPrint Box

LC-3DPrint Box

Revolutionary curing tool equipped with 12 strategically positioned UV lamps that irradiate the product from all sides, ensuring a uniform UV cure cycle.

LC-3DMixer

LC-3DMixer

Developed to keep 3D printing materials at the optimum consistency, this roller/tilter agitator system constantly mixes the material, keeping it in the ideal condition and always ready for use.

3D Sprint

Figure 4 uses 3D Sprint™, 3D Systems’ advanced software for preparing, editing, printing and managing files from a single, intuitive interface. 3D Sprint enables customers to significantly reduce the cost of running 3D printers by eliminating the need for expensive software from third-party suppliers. 3D Sprint also automatically generates exceptionally efficient media that require much less material, increasing savings and avoiding waste.

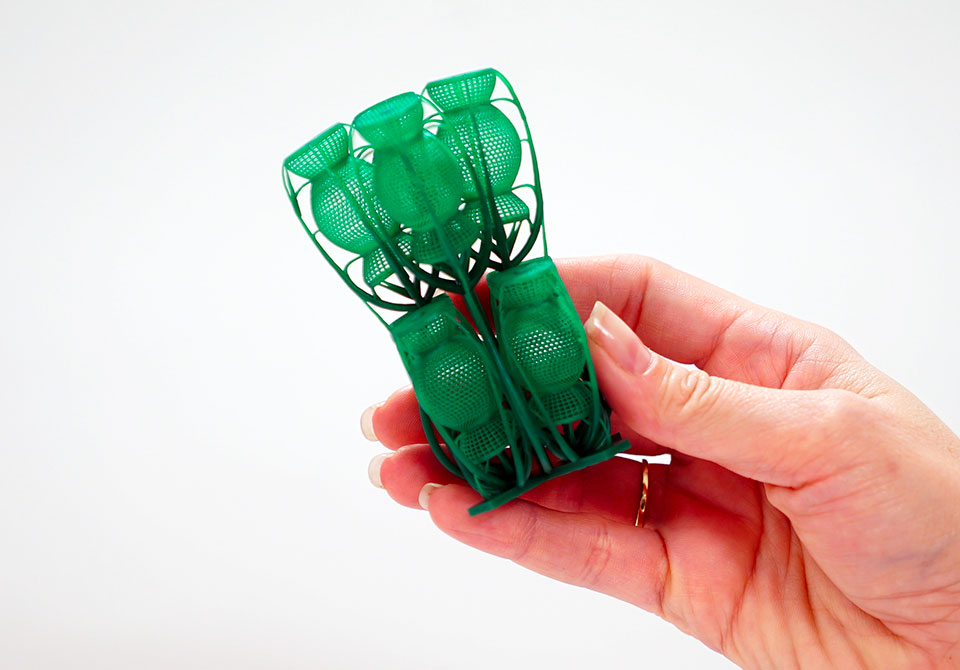

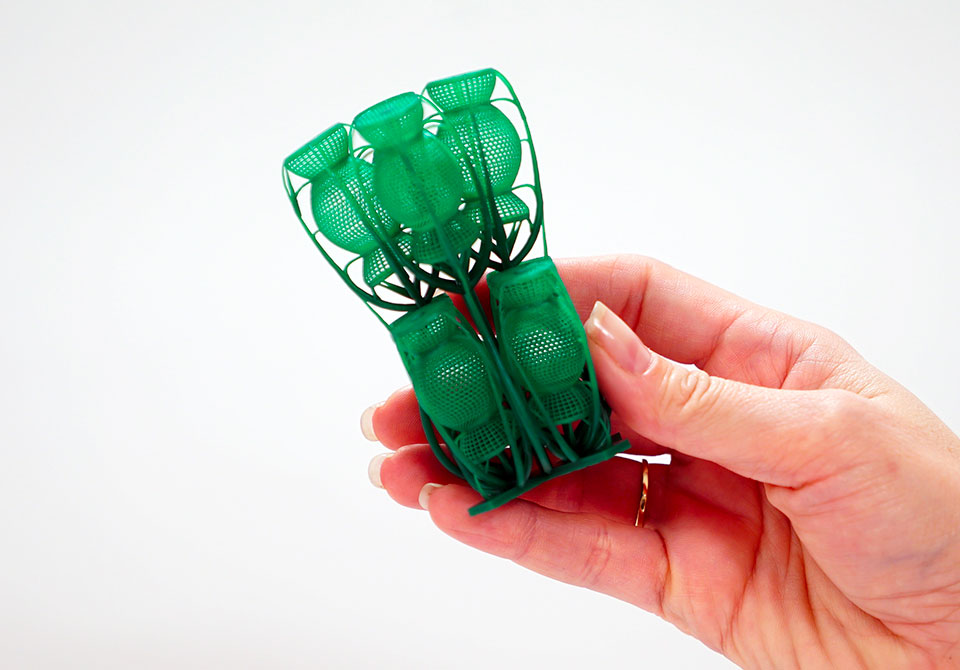

With Figure 4 Jewelry you can create:

- accurate, repeatable and detailed direct casting patterns. Print with a material that is easily and quickly transformed into high quality final parts.

- master patterns for moulds. Master models can be moulded with the heat-resistant material Figure 4 JCAST-GRN 10.

- jewellery prototyping and verification. Creates precise and fine details to ensure the final fit of the stone setting.

Ultra-fast printing

Figure 4 Jewelry enables 3D printing of complete jewellery plates four times faster than other printers used in costume jewellery.

High-quality models

Figure 4 Jewelry offers a high surface finish and guarantees fine resolution and smooth walls.

Precise details

The moulded parts are optimised for all sizes and geometries, from the thinnest to the thickest.

Reducing labour costs

The substrates are easily removed and leave a smooth surface finish, reducing post-processing and polishing time and thus production costs.

Download

Contact us to get more information and request a quote