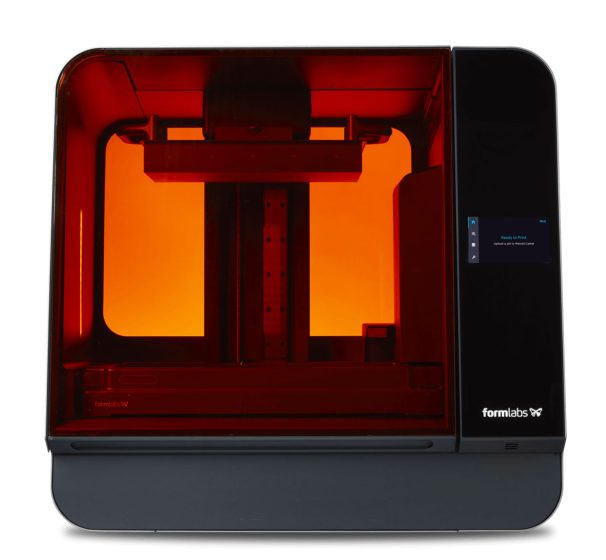

Fuse 1+ 30W

The powder 3D printer with the best price-performance and speed ratio

With Fuse 1+ 30W you produce high-performance functional parts in hours instead of days. The features of Fuse 1+ 30W allow you to use powder in innovative ways and minimize waste. The new nitrogen reserve option allows you to create an inert gas environment during the printing process, and eliminate unwanted oxygen from the sintering environment. Parts printed in an inert environment are less brittle and more ductile. This results in better end-use parts, particularly for industries where robustness is critical, such as automotive and aerospace.

- Thickness

- 110 μm

- Laser power

- 30 W

- Laser (FWHM)

- 247 μm

- Dimensions

- 165 × 165 × 300 mm

Nylon 11 CF Powder

New material specially developed for Fuse 1+ 30 W. Combining the properties of nylon with carbon fiber results in an extremely stable material ideal for applications where high stiffness and strength are required. For stiff and lightweight end-use parts that can withstand repeated impacts.

Nylon 11 CF Powder is ideal for:

- Replacement and replacement parts for parts normally made of metal

- Equipment, jigs, jigs and fasteners

- Impact-resistant equipment

- Prototypes and functional composite components.

Tensile strength: 50 MPa

Modulus of elasticity: 1850 MPa

Elongation at break: 11 %.

* Material properties may vary depending on part design and manufacturing processes. It is the manufacturer's responsibility to validate the suitability of molded parts for their intended use.

Nylon 12 Powder

With its balance of strength and precision, Nylon 12 Powder is an extremely versatile material suitable for both functional prototyping and the production of complex assemblies and end-use parts that are durable and have high environmental stability. Nylon 12 Powder is designed specifically for use with Fuse 1.

Nylon 12 Powder is ideal for:

- High-performance prototyping

- Small batch production

- Permanent files, fasteners and fixtures

- Sterilizable biocompatible parts

Tensile strength: 50 MPa

Modulus of elasticity: 1850 MPa

Elongation at break: 11 %

* Material properties may vary depending on part design and manufacturing processes. It is the manufacturer's responsibility to validate the suitability of molded parts for their intended use.

Nylon 11 Powder

Nylon 11 Powder, for ductile and strong parts, is a high-performance nylon material of biological origin, suitable for functional prototyping and small batch production. Nylon 11 Powder can be used to mold parts that bend and resist impact.

Nylon 11 Powder is ideal for:

- Impact-resistant prototypes, templates and fasteners

- Thin-walled ducts and housings

- Carabiners, hooks and hinges

- Orthotics and prosthetics.

Tensile strength: 49 MPa

Modulus of elasticity: 1573 MPa

Elongation at break: 40 %.

* Material properties may vary depending on part design and manufacturing processes. It is the manufacturer's responsibility to validate the suitability of molded parts for their intended use.

Nylon 12 GF Powder

The high amount of glass fiber present in Nylon 12 GF Powder enables 3D printing of rigid and compact parts with high thermal stability properties. Nylon 12 GF Powder is ideal for making prototypes or end-use parts that are required to have load-bearing capacity and high temperature resistance. The specific properties of Nylon 12 GF mean that the molded part will not warp and will maintain its dimensional accuracy even when exposed to high temperatures and when subjected to the application of a load.

Nylon 12 GF is ideal for

- rigid and functional prototypes

- jigs and fixtures

- replacement parts

- parts subjected to high temperatures

- parts with threads and housings where these characteristics are required.

Regeneration rate: 30-50%

Modulus of elasticity: 2800 MPa

Temperature of thermal distortion at 1.8Mpa: 113° C

* Material properties may vary depending on part design and manufacturing processes. It is the manufacturer's responsibility to validate the suitability of molded parts for their intended use.

TPU 90A

For flexible parts suitable for everyday use. With high elongation and exceptional tear strength, TPU 90A Powder enables in-house production of functional prototypes and very strong end-use parts.

TPU 90A makes it possible to reduce the cost per part due to a 20% remanufacturing rate.

TPU 90A is ideal for:

- wearable devices that are safe for skin contact

- gaskets, joints, masks, belts, caps and tubes

- protective sports equipment

- soles, splints, orthotics and prosthetics

- padding, shock absorbers, cushions and clamps

Prototyping

Verify and optimize your design to achieve a product that is perfect in every aspect. 3D printing enables extremely fast, easy and cost-effective production of high-quality prototypes, which are essential for experimenting with alternatives or verifying every functional, aesthetic and design aspect, avoiding slowdowns and errors.

Production

Additive manufacturing wants to propose itself as the production of the future, whether for private use, independent realities or industrial production. To improve industrial productivity through 3D printing, 3DZ offers a wide range of solutions capable of meeting the needs of a variety of professional sectors.

Fuse Sift 120V/230V

Integrated workstation that combines part extraction as well as powder recovery, storage and mixing in one device. Extremely convenient and compact, it provides the best functional efficiency available in the selective laser sintering market.

PreForm

Quick and easy print setup, fast and reliable one-click printing, and simplified management and tracking. With PreForm, Formlabs’ print preparation software (free to download and use), it will be easy to import part files in STL or OBJ format, orient and arrange models, calculate estimated print time, monitor your printers, and upload design files.

PreForm’s part consolidation algorithms can automatically arrange numerous models within the same print job.

Strengths

Precise and functional parts in 24 hours, thanks to the powerful 30W laser and high-performance materials

Selective Laser Sintering (SLS) uses a laser to precisely melt nylon powder to create solid, lightweight parts. The laser in Fuse 1+ has a power rating of 30 W and enables significantly higher printing speeds.

Fuse 1+ 30 W can boast a range of high-performance printing materials: Discover exclusive new materials, such as Nylon 11 with carbon fiber, and get the most performance from existing materials with active powder management and inert gas printing capability.

Less waste and high return on investment: by optimizing part density on the work area and maximizing powder recovery, with Fuse + 30W you print without waste and reduce the cost per part.

Fast and uninterrupted printing

Print volume: 165 x 165 x 320 mm: for making larger, higher volume parts.

An additional, removable print chamber allows you to print continuously and reduce downtime.

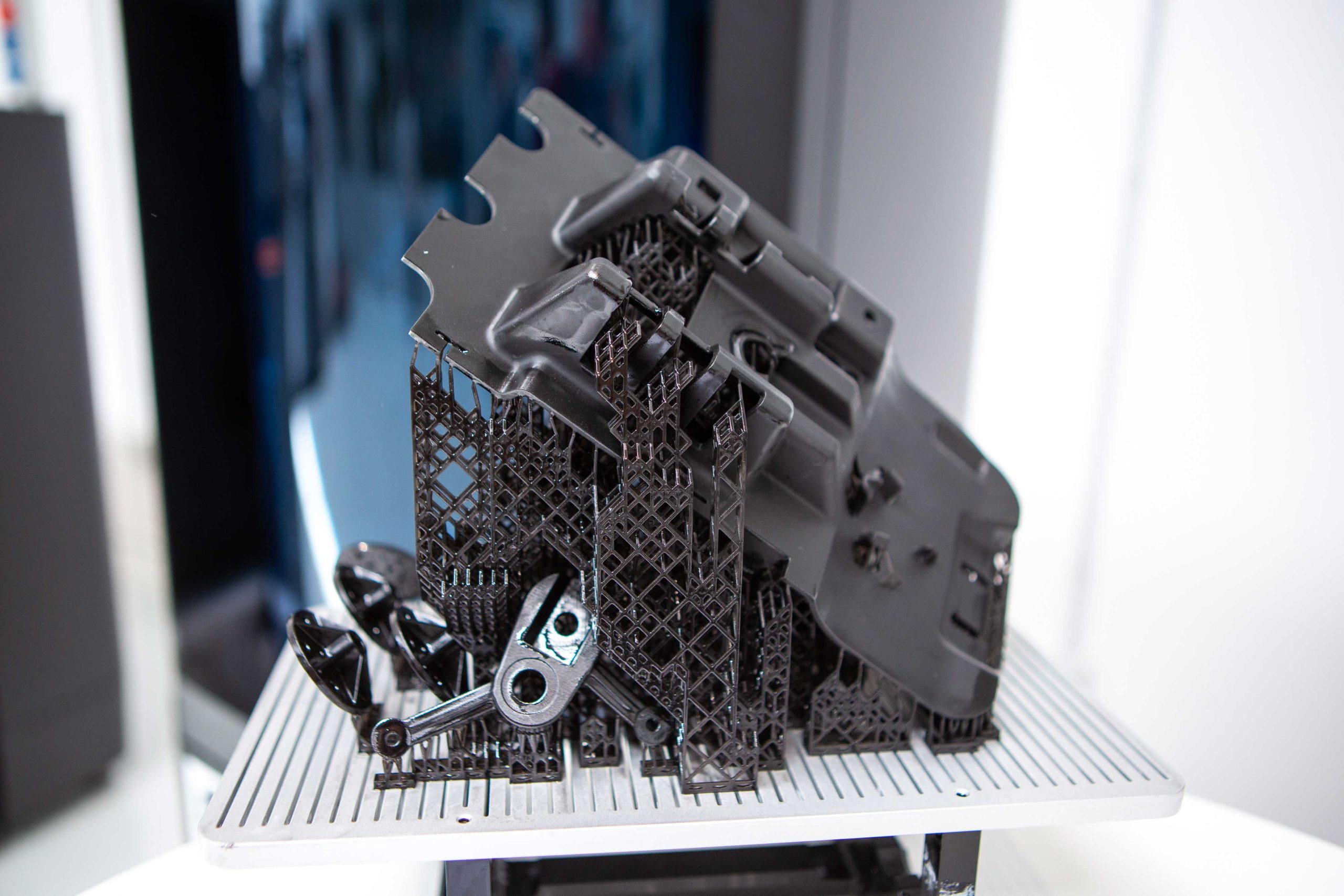

Powder supports printed parts: so you can fill the print area with as many parts as you need, saving time in post-curing as well.

Download

Contact us to get more information and request a quote