The new material, similar to rubber, for the production of elastomeric parts, even in small volumes and on-demand

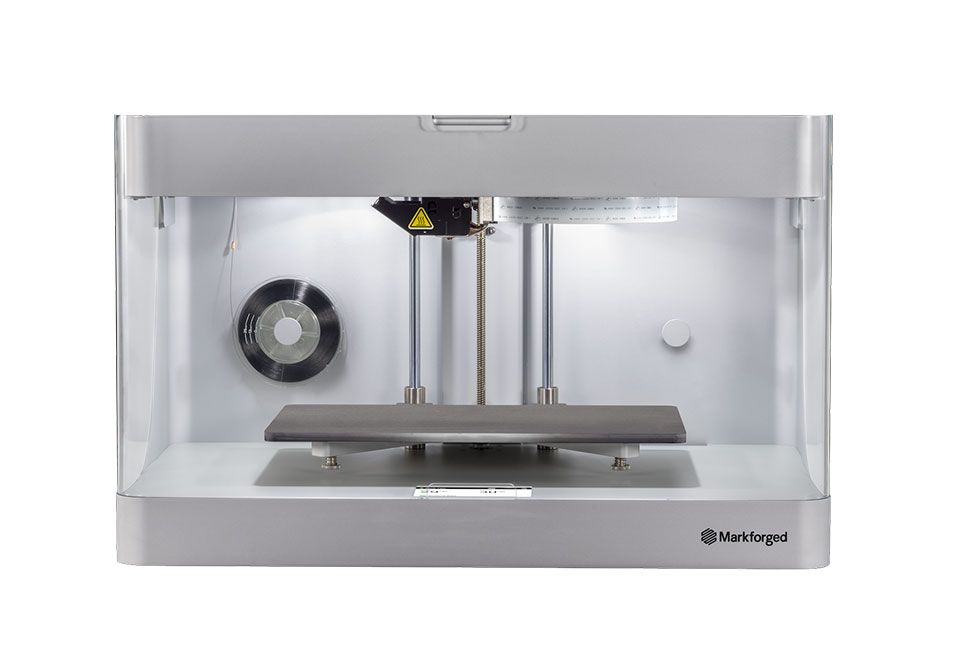

Smooth TPU 95A material by Markforged to make flexible parts with 3D printing

TPU (thermoplastic polyurethane) is a rubber-like material suitable for the production of flexible and impact-resistant parts.

Because of its characteristics, it lends itself to the production of parts such as gaskets, shock absorbers, hoses, and transmission belts.

Smooth TPU 95A, the new filament from Markforged, makes it possible to obtain parts that have the same functionality as parts made with traditional systems, but offers the great advantage of executing even small custom and on-demand designs quickly and without additional costs.

Classic production methods of flexible materials normally require long lead times, high investment and numerous processing steps, making them feasible only for large quantities.

Smooth TPA 95A, on the other hand, by greatly simplifying the process allows these parts to be made even for prototypes or when the required quantities are minimal.

Features:

- Flexibility

- Impact resistance

- Elongation at break of 500%

- Shore A hardness of 95

- High surface quality

- Good mechanical deformability

Applications

- Replacement of traditional manufacturing

High-quality flexible and impact-resistant finished parts in low volumes

Design validation prototypes before going into or scaling up production

Seals

Shock Absorbers

Flexible Hoses

Transmission belts and bands

Wheels and Treads

Smooth TPU also makes it easy to 3D print flexible parts

3DZ advises you

You want to learn more about Markforged printing solutions? Contact us: one of our 3D printing experts will introduce you to the benefits your company can gain from this printing technology and the ability to reinforce your parts with fibers when strong parts are needed.

3DZ is a reseller of the best 3D printing and scanning brands with over a decade of experience and over 2000 industrial 3D printers installed. We guide you in choosing the right printing technology and materials for your specific need.