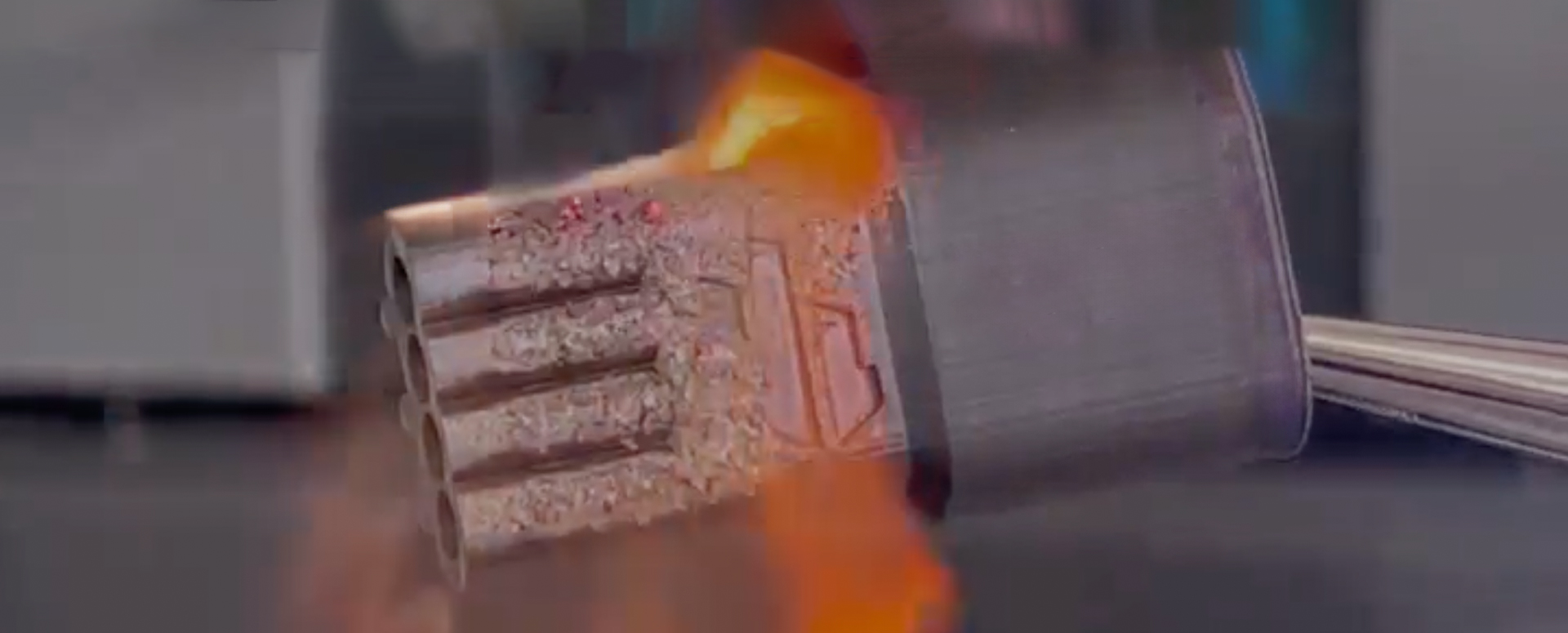

xPRO9400-FR: High productivity flame retardant resin for transportation, electronics and more

The xPRO9400 FR is the new resin from Nexa3D’s XipPro that exceeds all the flame resistance requirements of major industrial manufacturing sectors such as automotive, rail, aerospace, electronics and more. In fact, this material not only has excellent mechanical properties but also exceeds with flying colors the flammability requirements of the UL-94 reference standard.

It is ideal for the production of automotive, railway and aerospace parts, custom jigs and fixtures, and more. It is distinguished by its low viscosity, easy processability and exceptional temperature resistance. Developed in partnership with BASF.

Mechanical properties

- Tensile strength of 78 MPa, thus comparable to a loaded polyamide;

- Elongation at break of about 3%, making it a strong material but with brittle breaking behavior;

Thermal characteristics

- Heat resistance up to 236 °C at 0.45 MPa, making it ideal for high-temperature applications;

- Glass transition temperature of 175 °C, making it suitable for low-temperature applications (even below 0 °C).

Flame-resistant characteristics

- Grade V0 according to UL-94 standard from thicknesses of 2 mm;

- Grade V1 according to UL-94 standard starting from thicknesses of 1 mm.

This makes the material ideal for electronic, medical and automotive applications, and certifiable for some components for the rail and aviation industries;

- Railway certification (R22), according to DIN EN 45545-2 with risk level HL1 (with minimum cross-section equal to 2 mm x 2.5 mm);

- Railway certification (R23, R24), according to DIN EN 45545-2 with risk level HL2 (with minimum section equal to 2 mm x 2.5 mm).

In addition, all test data on the amount of generation and density of smoke generated during combustion are available.

Ultimately, this material is ideal for all those applications that require very stringent flame-retardant requirements, not to mention, in addition, the high productivity and injection molding surface finish achievable through the use of Nexa3D’s super-fast LSPc 3D printing technology with XIP Pro.

Do you want to learn more about xPRO9400 FR?

Want to learn more about Nexa 3D's resin 3D printing technology and possible applications with this new flame retardant material? Request a contact with one of our 3D printing experts.

Contact Us