With Formlabs' new material, the casting process becomes accessible.

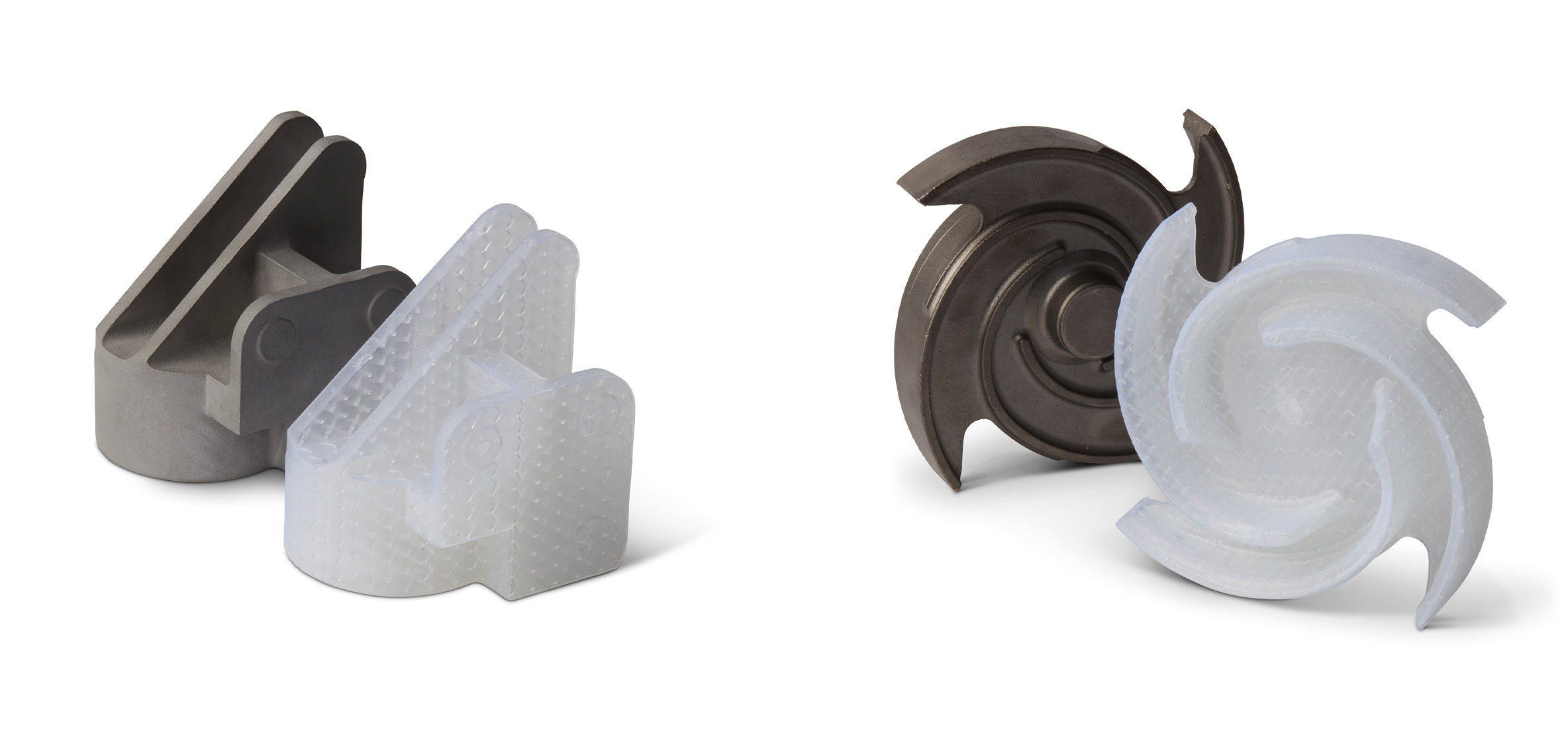

Clear Cast Resin is the latest innovative material developed by Formlabs for lost-wax casting, allowing models to be directly molded for coating and casting. This resin features extremely low thermal expansion, low ash residue and total absence of heavy metals.

In combination with crosslinking software, this resin is ideal for creating large parts and offers outstanding results in creating geometries over 3 mm thick.

Clear Cast Resin is compatible with Formlabs SLA printers Form 3+, Form 3L, Form 4.

Lost-wax casting is an industrial process that requires precision and cleanliness and until recently was accessible only to large companies. With this resin, detailed, cast-ready models can be quickly created without altering the normal workflow, thus reducing time and cost and greatly increasing production flexibility.

Key Features

- Clean burning: the resin ensures low ash residue production and total absence of heavy metals.

- Extreme accuracy: with a maximum deviation of 0.025 mm from the original design, Clear Cast Resin enables the creation of even large detailed models.

- Ease of use: the 3D printing workflow is simple and requires minimal training, reducing labor costs.

- Smooth surfaces: printed models have flawless finishes, minimizing post-processing.

The workflow with Clear Cast Rein

The workflow with Clear Cast Resin is extremely intuitive and optimized:

1. Design: uses crosslinking software to create a non-solid internal geometry, reducing residual ash and thermal expansion forces.

2. Print preparation: upload file to PreForm, select printer and Clear Cast Resin material.

3. Printing and washing: once the part is printed, wash it using Form Wash or Form Wash L, depending on the size.

4. Curing: dry the parts and cure them at 35°C for 15 minutes.

5. Preparation for casting: attach the parts to a casting tree, coat them and burn them at a temperature of 700-900°C.

6. Casting: perform the casting process as per the standard workflow.

Want to learn more about Clear Cast and 3D printing for casting models?

Contact us. One of our printing experts is at your disposal.

Contact Us