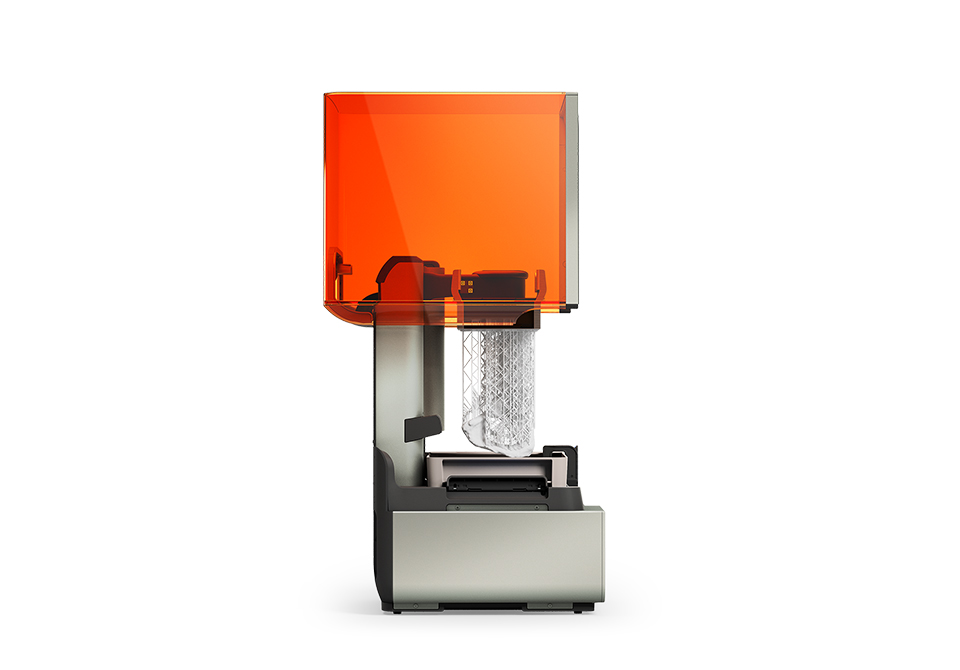

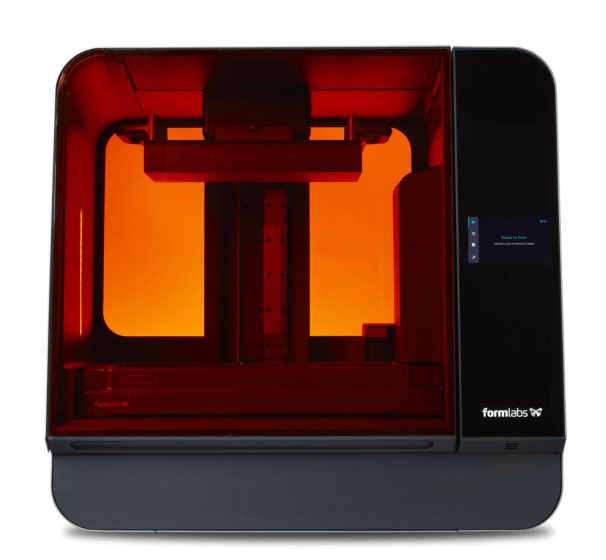

Form 4

Manufactures industrial parts in record time

Form 4 is Formlabs' new 3D printer, faster and more accurate.

It is versatile, intuitive and reliable.

It has a wide range of materials.

It makes parts that meet the tightest tolerances.

It offers surface quality comparable to injection molding.

The new Form 4 ecosystem allows most prints to be made in less than two hours or quick patterns in minutes.

- Technology

- Low Force Display (LFD)

- Print volume

- 20 x 12,5 x 21 cm

- Layer thickness (Y resolution)

- 25-300 micron

- XY resolution

- 50 micron

- Average print speed at 100 microns

- 40 mm/h

- Maximum print speed

- 100 mm/h

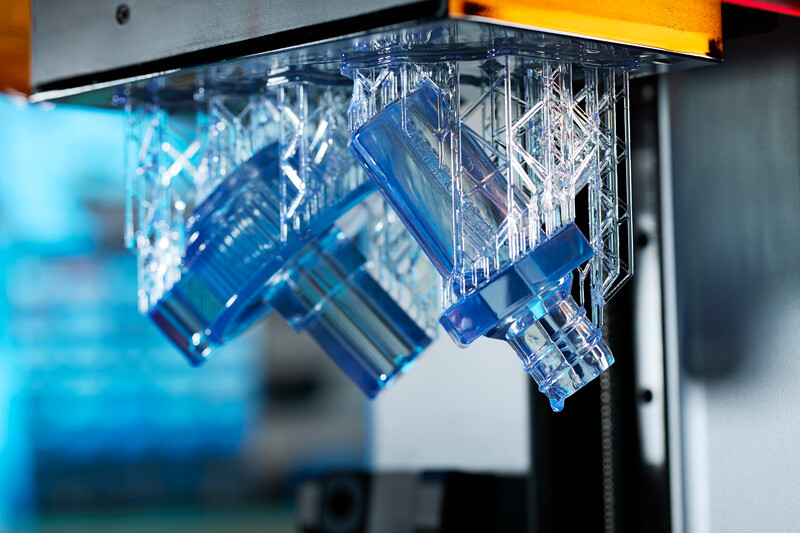

Clear Resin V5

Clear Resin V5 is a resin for making colorless, perfectly transparent parts that can be polished to near optical transparency. It creates rigid, durable parts with a smooth surface finish comparable to that achieved with acrylic. It is formulated for use with the new Form 4 ecosystem.

Ideal for:

- Transparent enclosures, optical components and lighting prototypes.

- Parts that show internal features

- Molds, jigs and other tools

- Fluid devices

White Resin V5

White Resin V5 is a standard general-purpose resin with an extraordinarily bright opaque white color that offers a perfect balance of print speed, high precision even in the most intricate details.

It creates rigid, durable parts with a surface finish comparable to that achieved by injection molding.

Ideal for:

- Prototyping shape and fit

- Presentation models with refined features and intricate details

- Anatomical models

- Templates and fixtures

Fast Model Resin

Fast Model Resin is Formlabs' fastest resin, capable of printing over 100 mm per hour. It prints dental models in minutes or large prototypes in less than two hours. It is formulated for use with the new Form 4 ecosystem and prints 3 times faster than previous formulations of Draft Resin

Ideal for:

- Initial prototypes for shape and feel

- Rapid design iterations

- Large models that can be printed quickly

- Dental models for thermoforming aligners

Grey Resin V5

Grey Resin V5 is an extraordinarily versatile general-purpose standard resin that offers the perfect balance of print speed, high precision, appearance, stiffness, and a simple, reliable workflow.

It creates rigid, durable parts with a surface finish comparable to that achieved by injection molding. Grey Resin V5 has an intense matte color that can accurately reproduce even the most intricate details. È

formulated for the Form 4 ecosystem, which allows it to print 3 times faster than the previous version.

Ideal for:

- Prototyping shape and fit

- Presentation models with refined features and intricate details

- Anatomical models

- Templates and fixtures

Black Resin V5

Black Resin V5 is a standard general-purpose resin with an exceptionally intense black color that offers the perfect balance of print speed, high precision, appearance, stiffness, and a simple, reliable workflow.

It creates rigid, durable parts with a surface finish comparable to that achieved by injection molding. Black Resin V5 has an intense matte color that can accurately reproduce even the most intricate details. È

formulated for the Form 4 ecosystem, which enables printing 3 times faster than the previous version.

- Prototyping shape and fit

- Presentation models with refined features and intricate details

- Anatomical models

- Templates and fixtures

Prototipazione

Verify and optimize your design to achieve a product that is perfect in every aspect. 3D printing enables extremely fast, easy and cost-effective production of high-quality prototypes, which are essential for experimenting with alternatives or verifying every functional, aesthetic and design aspect, avoiding slowdowns and errors.

Form Wash 2nd Gen

Automatically cleans printed parts efficiently and precisely with isopropyl alcohol or other solvents. Leave the parts on the printing plate when you transfer them from the printer to the Form Wash, or remove them and place them in the wash basket. The parts are agitated in a solvent with an impeller, which allows every nook and cranny to be cleaned to perfection, automatically and for the appropriate length of time. When finished, the Form Wash automatically pulls out the parts to air dry.

PreForm®

PreForm® is the software that makes printing preparation easy and intuitive.

It prepares templates automatically in minutes, loads them on the printer, and starts printing.

PreForm’s algorithms automatically set the layout, orientation, and media of your print so that you can print without the need for specialized training.

PreForm provides detailed information about your prints, has validated settings, offers the ability to customize settings. Supports the most popular file formats.

Allows printing to be started remotely. Checks printability of files in real time. Provides for advanced media generation and offers intelligent automatic part orientation.

Very fast

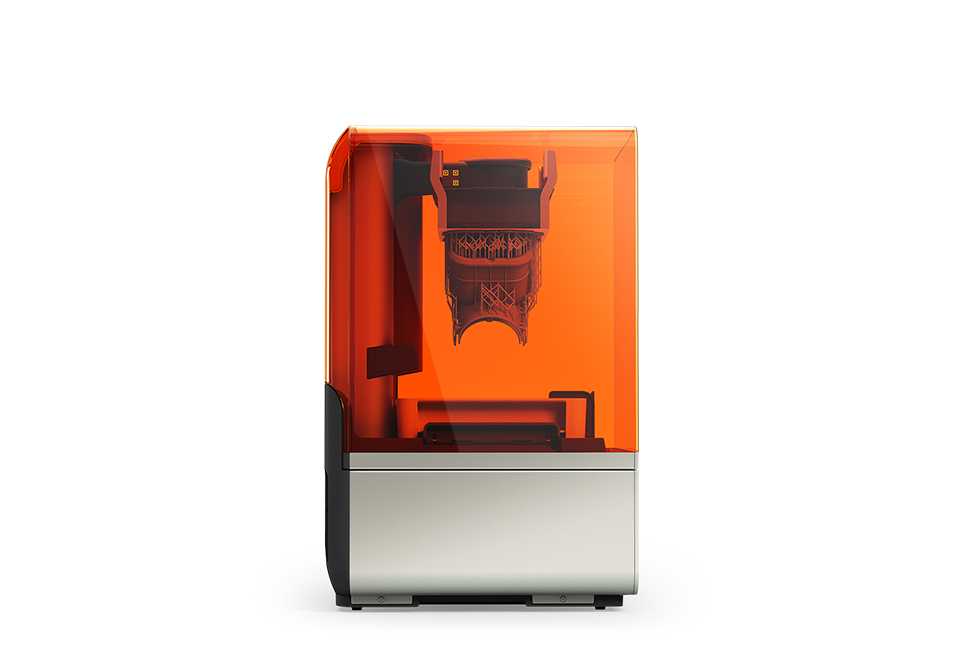

With print speeds up to four times faster than previous Form series printers and a 30 percent larger print volume, Form 4 represents an evolution in resin 3D printing.

Form 4's speed comes from Formlabs' new print engine with Low Force Display™ technology, which combines powerful LEDs, collimation lenses, optical filters, and a liquid crystal display that cure each resin layer quickly, regardless of part size or quantity.

The reliability and ease-of-use of the Formlabs ecosystem enable most prints to be made in less than two hours or quick models in minutes.

Flexible

In combination with Formlabs' extensive catalog of materials, Form 4 opens the way to new opportunities for innovation and production. With so many familiar materials and 5 newly formulated resins specifically for Form 4, the applications are countless.

With the Open Platform option, the possibilities then truly extend to every industry.

Intuitive

Learning to use Form 4 is child's play. Anyone can be up and running in 15 minutes.

Reliable and precise for extraordinary parts

Form 4 has an unmatched printing success rate. It makes parts that are no match for injection molded parts.

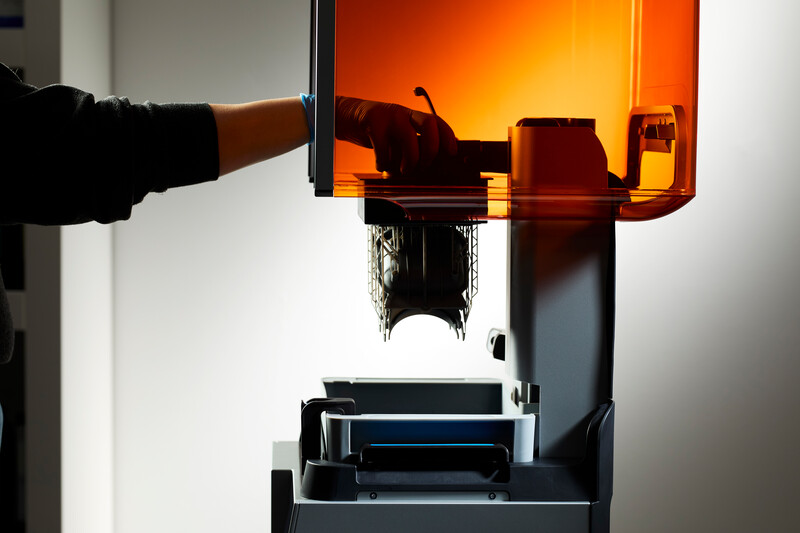

Build Platform Flex

Form 4 Build Platform Flex, with its Quick Release Technology, allows parts to be quickly and easily removed from the print surface, without using any tools. Build Platform Flex, recommended for almost all types of printing, eliminates the risk of damaging parts and streamlines the workflow.

Resin Tank

Form 4's Low Force Display (LFD)™ 3D printing technology uses a flexible yet durable reservoir with a dual-layer coating film to ensure uniform, high-quality prints. Each resin tank includes a reusable lid, which allows for stacking of multiple tanks and storage of resin outside the machine. With a dedicated tank for each type or color of resin, changing print materials is even easier.

The resin tank for Form 4 is designed to last and provide consistent performance for at least 75 000 print layers (averaging about 1-2 years of use).