Figure 4 Modular

The most productive industrial 3D printer for pre-series parts

Figure 4 Modular allows the economical production of parts in a flexible modular system architecture, with the possibility to add separate accessories for post-processing for polymerization. 3D Systems’ modular platform provides high quality components in a wide range of rugged materials. Ideal for rapid functional prototyping and conceptual models, durable plastic parts, digital texturing applications, elastomer parts, rapid molding tools, models and assemblies, as well as traditional urethane and injection molding processes. Thanks to its scalability, with up to 24 printing engines, Figure 4 Modular allows the economical production of parts in a flexible modular system architecture, with the possibility to add separate accessories for post-processing for polymerization.

- Print volume

- 124,8mm x 70,2mm x 346 mm

- Minimum layer thickness

- 0,01 mm

- Resolution

- 1920 x 1080 pixel

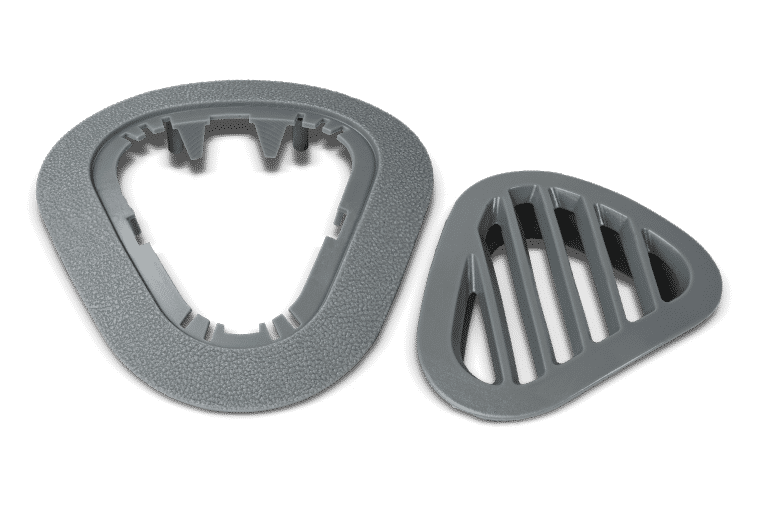

Figure 4 Rigid Gray

Figure 4 Tough 65C Black

For high performance in terms of strength combined with flexibility for high volume production. Designed for applications subject to high mechanical loads, such as small snap-on parts, holders, handles and fasteners for consumer products, wearable devices and general purpose parts requiring precision and accurate detail.

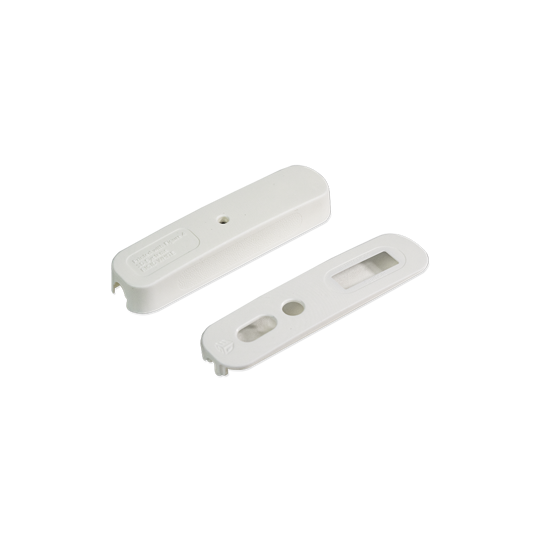

Figure 4 Tough Clear

Transparent material that is UV and moisture stable over time, impact resistant and ideal for fluid control applications, lenses, light covers.

Figure 4 Tough 60C White

For high performance in terms of strength combined with flexibility for high volume production. Suitable for high and repeatable mechanical loads at high temperatures. Ideal for wearables that touch skin and medical parts requiring ISO-10993-5 and 10993-10 biocompatible capability.

Figure 4 High Temp 150C FR Black

Resina ritardante di fiamma priva di alogeni è ideale per parti di produzione in plastica per le applicazioni dei settori aerospaziale e difesa, automotive e sport motoristici, nonché elettronica di consumo. Questo materiale è ideale per produrre protezioni, pannelli e alloggiamenti rigidi e piccole parti della cabina per aerei cargo e passeggeri. La lavorazione non presenta difficoltà, poiché questo materiale è facilmente gestibile e può essere utilizzato così come viene fornito, senza fusione o stampa a temperature elevate.

Figure 4 PRO-BLK 10

High-performance rigid material for production parts

Figure 4 RUBBER-BLK 10

Durable material, similar to hard rubber

Figure 4 RUBBER-65A BLK

High-performance rubber with tear resistance

Figure 4 FLEX-BLK 20

Highly stable, resistant and flexible plastic

Figure 4 FLEX-BLK 10

Flexible and durable production material, similar to polypropylene

Figure 4 TOUGH-BLK 20

Durable material with long-term environmental stability

Figure 4 TOUGH-GRY 10

High-speed, rigid production material dark grey

Figure 4 TOUGH-GRY 15

Rigid, inexpensive, grey production material

Figure 4 Rigid White

High-performance white opaque rigid plastic

Figure 4 ELAST-BLK 10

Rubber-like, elastomeric design material

Figure 4 HI TEMP 300-AMB

High-temperature resistant translucent plastic with HDT above 300 °C

Figure 4 EGGSHELL-AMB 10

Process-optimised material for silicone casting equipment

Figure 4 MED-AMB 10

Rigid, translucent material that can be sterilised and tested at high temperatures

Figure 4 Tough V0 FR Black

Durable, flame-retardant material for high-performance additive manufacturing, conforming to UL 94 V0 standards.

Verify and optimise your design for a perfect product in every respect. 3D printing makes it possible to produce high-quality prototypes extremely quickly, easily and inexpensively, which are essential for experimenting with alternatives or verifying every functional, aesthetic and design aspect, avoiding delays and errors.

Production

LC-3D Print Box

Revolutionary curing tool equipped with 12 strategically positioned UV lamps that irradiate the product from all sides, ensuring a uniform UV curing cycle.

https://youtu.be/KtJU6aOMDwI

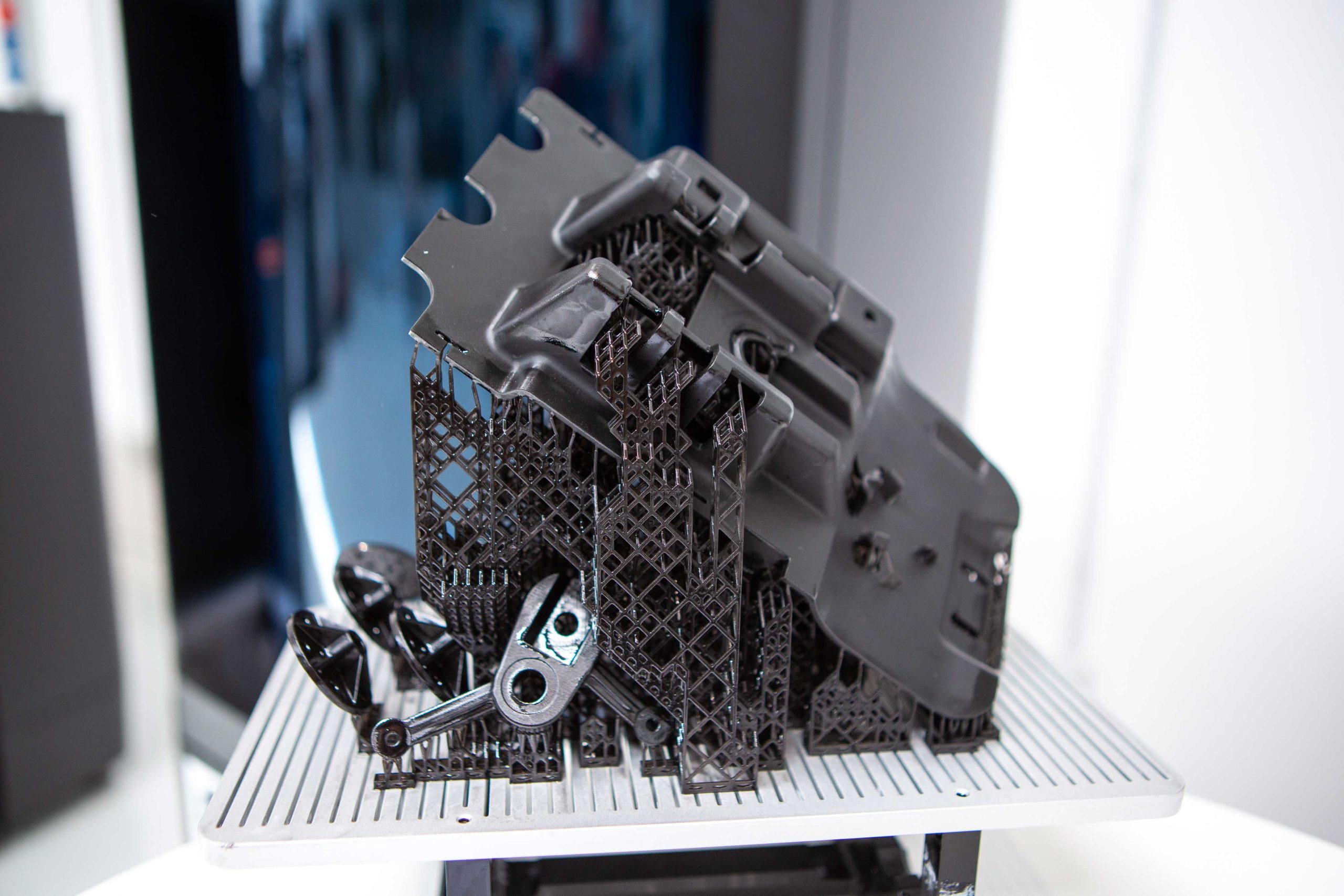

3D Sprint

Figure 4 uses 3D Sprint™, 3D Systems’ advanced software for preparing, editing, printing and managing files from a single, intuitive interface. 3D Sprint enables customers to significantly reduce the cost of running 3D printers by eliminating the need for expensive third-party software. 3D Sprint also automatically generates exceptionally efficient media that require much less material, increasing savings and avoiding waste.

An affordable 3D manufacturing solution that grows with your business

3D Systems' modular platform produces high-quality parts in a wide range of strong and durable materials. Ideal for rapid functional prototyping, conceptual models, durable plastic parts, digital texturing applications, elastomer parts, thermoforming moulds, patterns and assemblies, as well as traditional injection moulding and urethane moulding processes.

Thanks to its scalability, which allows up to 24 print engines to be connected, the Figure 4 Modular enables the cost-effective production of parts in a modular and flexible system architecture, with the possibility of adding separate post-processing and curing accessories.

Figure 4 Modular allows functional iteration of prototypes and small-scale production even on the same day at incredible print speeds. New designs ready to be delivered in no time.

With its ability to adapt to your production needs, the Figure 4 Modular is an affordable manufacturing solution that grows with your business. The basic 3D printer configuration consists of a single printer and a central controller. It can be easily scaled up to 24 print modules on a single controller, with layout configuration flexibility that allows you to quickly ramp up production without disrupting the shop floor.

Contact us for more information and a quote