ProX SLS 6100

The most reliable production 3D printer

The ProX SLS 6100 offers versatility to your applications, both for functional prototyping and for direct 3D production. Choose from industrial nylon 11 with DuraForm ProX EX BLK or DuraForm ProX PA nylon 12, fire retardant powder based on nylon 12 with DuraForm ProX FR1200, DuraForm ProX HST fiber reinforced, DuraForm ProX GF glass fiber reinforced and DuraForm ProX AF+ aluminum fiber reinforced. DuraForm ProX PA can meet ISO 10993-5 and 10 standards.

- Print volume

- 381 x 330 x 460 mm

- Layer thickness

- 0.08 – 0.15 mm

- Print speed

- 2,7 l/h

- Recycling and dust management

- Fully automatic

DuraForm ProX EX BLK

Nylon 11-based material resistant to fatigue and oils. Designed for intensive and repeated use in harsh environments.

DuraForm ProX PA nylon 12

DuraForm ProX FR 1200

Flame-retardant nylon 12-based plastic with an excellent surface finish.

DuraForm ProX HST

Fibre-reinforced engineering material with excellent stiffness and resistance to high temperatures. Non-conductive and transparent to RF. For testing and use in harsh environments.

DuraForm ProX GF

Glass-reinforced material for durable and rigid prototypes and for the production of small and medium batch parts requiring high rigidity and heat resistance.

DuraForm ProX AF+

Aluminium-filled material with consistent mechanical properties, high stiffness and metallic surface finish.

DuraForm ProX EX NAT (SLS)

Durable Nylon 11-based material for production applications subject to repeated cycles, even in harsh environments.

DuraForm PAx Natural (SLS)

SLS material with high impact resistance, high elongation and high recyclability with properties similar to injection-moulded polypropylene for strong, lightweight and quality parts.

DuraForm PAx Black

SLS material with high impact resistance, high elongation and high recyclability. It has similar properties to injection-moulded polypropylene to make strong, lightweight and high-performance parts

Prototyping

Verify and optimise your design for a perfect product in every respect. 3D printing makes it possible to produce high-quality prototypes extremely quickly, easily and inexpensively, which are essential for experimenting with alternatives or verifying every functional, aesthetic and design aspect, avoiding delays and errors.

Production

Additive manufacturing aims to be the production of the future, whether for private use, independent businesses or industrial production. Improving industrial productivity through 3D printing and 3DZ offers a wide range of solutions to meet the needs of a variety of professional sectors.

Tooling

Make everything you need quickly and in-house easily and inexpensively.

Thanks to 3D printing, the tooling of machine tools, the rapid production of parts, complete tools or tools required for production can be completely internalised, avoiding the costs of an external printing service and eliminating unproductive waiting times.

Shot peening

Excess dust removal

Manual process

Single-piece process

Blowing

Removal of microspheres or residual free dust from the previous step

Manual/automatic process

Single-piece process

Impregnation/colouring

Manual/automatic impregnation

Graphite shot peening

Tumbling

Painting

3D Sprint

The ProX 6100 uses 3D Sprint™, 3D Systems’ advanced software for preparing, editing, printing and managing files from a single, intuitive interface. 3D Sprint enables customers to significantly reduce the cost of running 3D printers by eliminating the need for expensive third-party software. 3D Sprint also automatically generates exceptionally efficient media that require much less material, increasing savings and avoiding waste.

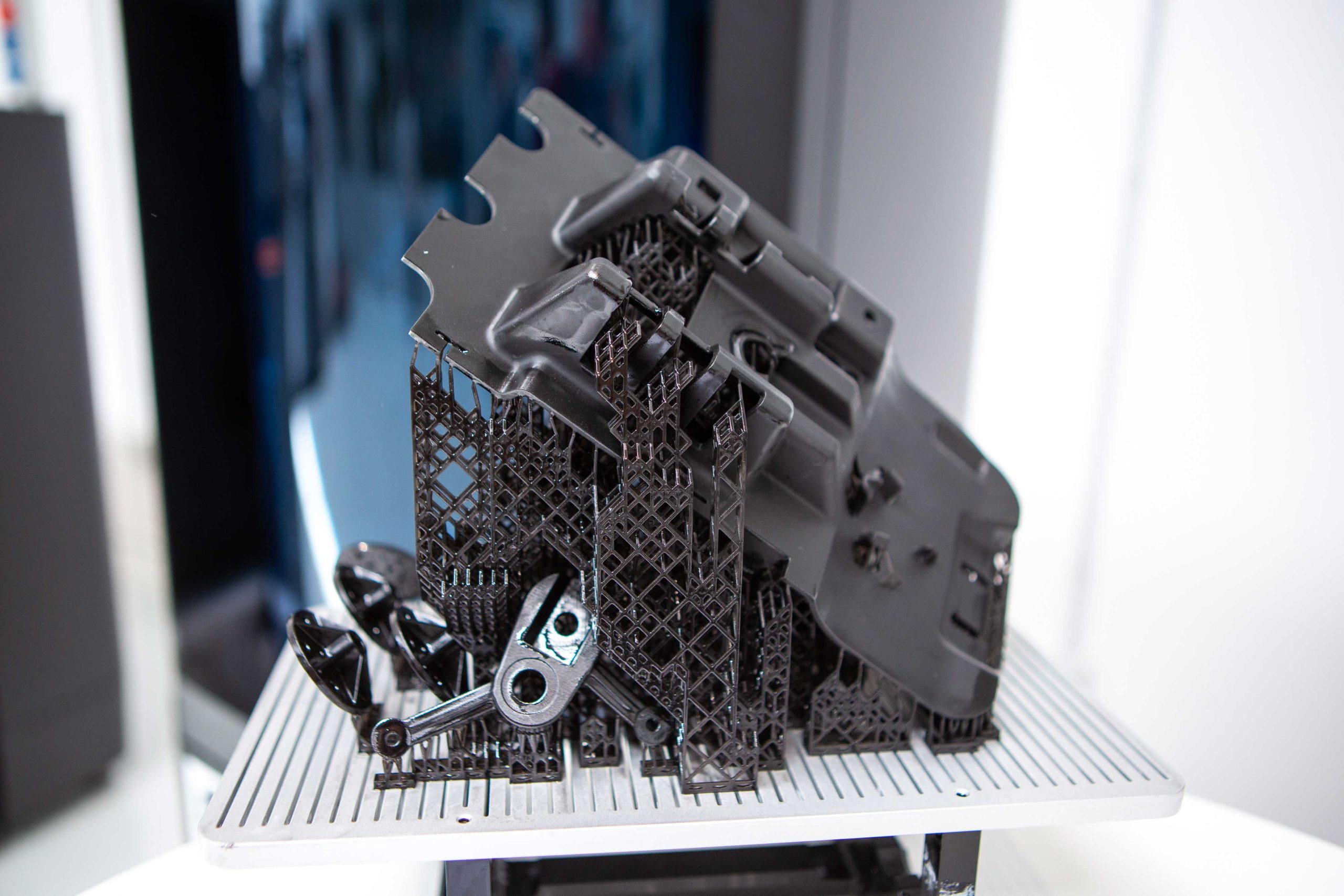

Production of robust and functional nylon parts.

The best quality for nylon-manufactured parts, with fast lead times, automated production tools and 20% lower costs.

Produce durable parts from a range of optimised, validated and quality-assured production-grade nylon materials with uniform 3D mechanical properties.

The ProX SLS 6100 offers versatility to your applications, whether for functional prototyping or direct 3D production. Choose from industrial nylon 11 with DuraForm ProX EX BLK or DuraForm ProX PA nylon 12, DuraForm ProX FR1200, DuraForm ProX HST fibre reinforced, DuraForm ProX GF glass fibre reinforced and DuraForm ProX AF+ aluminium fibre reinforced. DuraForm ProX PA is capable of meeting ISO 10993-5 and 10 standards.

Automated production tools, a new air-cooled laser, remarkably high productivity, 95% material efficiency and repeatability, combined with a competitive initial purchase price, reduce the total cost of operation by 20% compared to similar printers. The material quality control (MQC) system provides automatic mixing and recycling, while providing material transport to the printer without manual intervention.

With faster build times than other SLS printers in its price range, high-performance nesting and high-density capabilities for a 25 per cent larger production volume, the ProX SLS 6100 delivers production-quality parts in a fast and efficient process.

Improved surface finish

Highest resolution and edge definition

High accuracy and repeatability

Uniform part properties

Contact us to get more information and request a quote