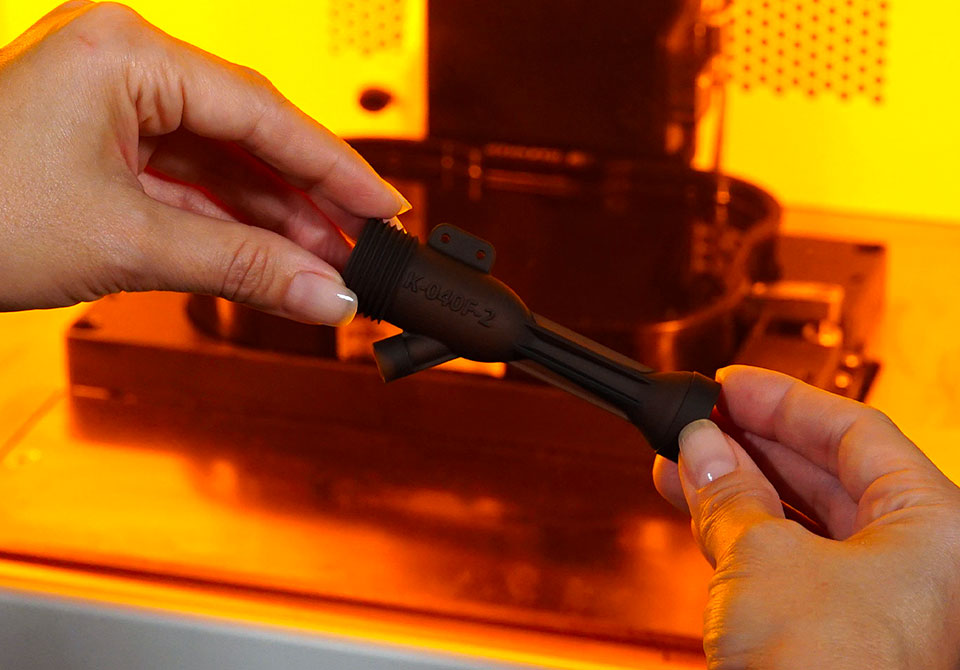

Figure 4 Standalone

Superfast and affordable, the 3D printer for low-volume production

Figure 4 Standalone is the affordable and versatile 3D printer for rapid prototyping and small batch industrial production. With its high printing speed and ease of use, it ensures optimized management at every stage of a project for increased productivity, repeatability and reduced operating costs. Extremely flexible, it uses a wide range of materials developed to meet different performance and application requirements, always ensuring high-quality, durable and accurate results.

- Printing volume

- 124.8mm x 70.2mm x 196 mm

- Resolution

- 1920 x 1080 pixel

- Pixel Pitch

- 65 microns

- Certifications

- FCC, CE, EMC

Figure 4 Rigid 140C Black

Rigid heat-resistant material combining high strength and high elongation for direct production of plastic parts without molds.

Figure 4 Tough Clear

Transparent production material designed to offer long-term environmental stability against UV radiation and moisture

Figure 4 Tough 60C White

White plastic for durable parts that combines impact resistance, elongation, and tensile strength.

Figure 4 Tough 65C Black

Black plastic for durable parts that combines impact resistance, elongation, and tensile strength.

Figure 4 High Temp 150°C FR Black

Rigid black flame retardant material that can be used for production parts requiring compliance with UL94 V0 and FAR 25.853 and 23.853

Figure 4 Rigid Gray

High-contrast gray plastic for durable parts with well-balanced thermal and mechanical properties.

Figure 4 RUBBER-65A BLK

High-performance rubber with tear resistance.

Figure 4 HI TEMP 300-AMB

Translucent plastic resistant to high temperatures with HDT above 300 °C.

Figure 4 EGGSHELL-AMB 10

Process-optimized material for silicone casting disposable models.

Figure 4 TOUGH-BLK 20

Durable material with long-term environmental stability.

Figure 4 MED-WHT 10

White rigid material that can be sterilized and tested at high temperatures.

Figure 4 MED-AMB 10

Rigid, translucent material that can be sterilized and tested at high temperatures.

Figure 4 FLEX-BLK 10

Flexible and durable production material, similar to polypropylene.

Figure 4 JCAST-GRN 10

Material for meltable jewelry applications for high-resolution models.

Figure 4 ELAST-BLK 10

Rubber-like, elastomeric design material.

Figure 4 Tough V0 FR Black

Durable, flame-retardant material for high-performance additive manufacturing, conforming to UL 94 V0 standards.

Figure 4 JCast GRN-20

For detailed, high-resolution jewellery models, direct casting with easy, clean burnout.

The post-processing units developed by 3D System to flank Figure 4 Standalone enable post-press needs (cleaning, drying, and curing) to be met effectively and purposefully.

LC-3D Print Box

Revolutionary curing tool equipped with 12 strategically placed UV bulbs that irradiate the product from all sides, ensuring a uniform UV cure cycle.

LC-3D Mixer

Developed to keep 3D printing materials at the optimum consistency, this roller/tilter agitator system constantly mixes the material keeping it in the ideal condition and always ready to use.

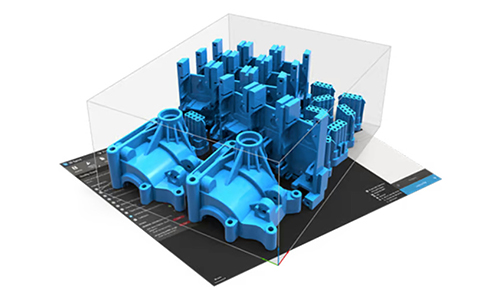

3D Sprint

Figure 4 uses 3D Systems’ advanced 3D Sprint™ software to prepare, edit, print and manage files from a single, intuitive interface. In fact, 3D Sprint enables customers to significantly reduce the cost of managing 3D printers, thereby reducing the need for expensive software from third-party vendors. 3D Sprint also automatically generates exceptionally efficient media that require much less material, increasing savings and waste avoidance.

Affordable

Allows you to cut costs by minimizing initial investment and all operating expenses. Provides industrial-grade durability, maintenance and service with rapid replacement service and 3D Connect™ for remote monitoring and diagnostics.

Fast

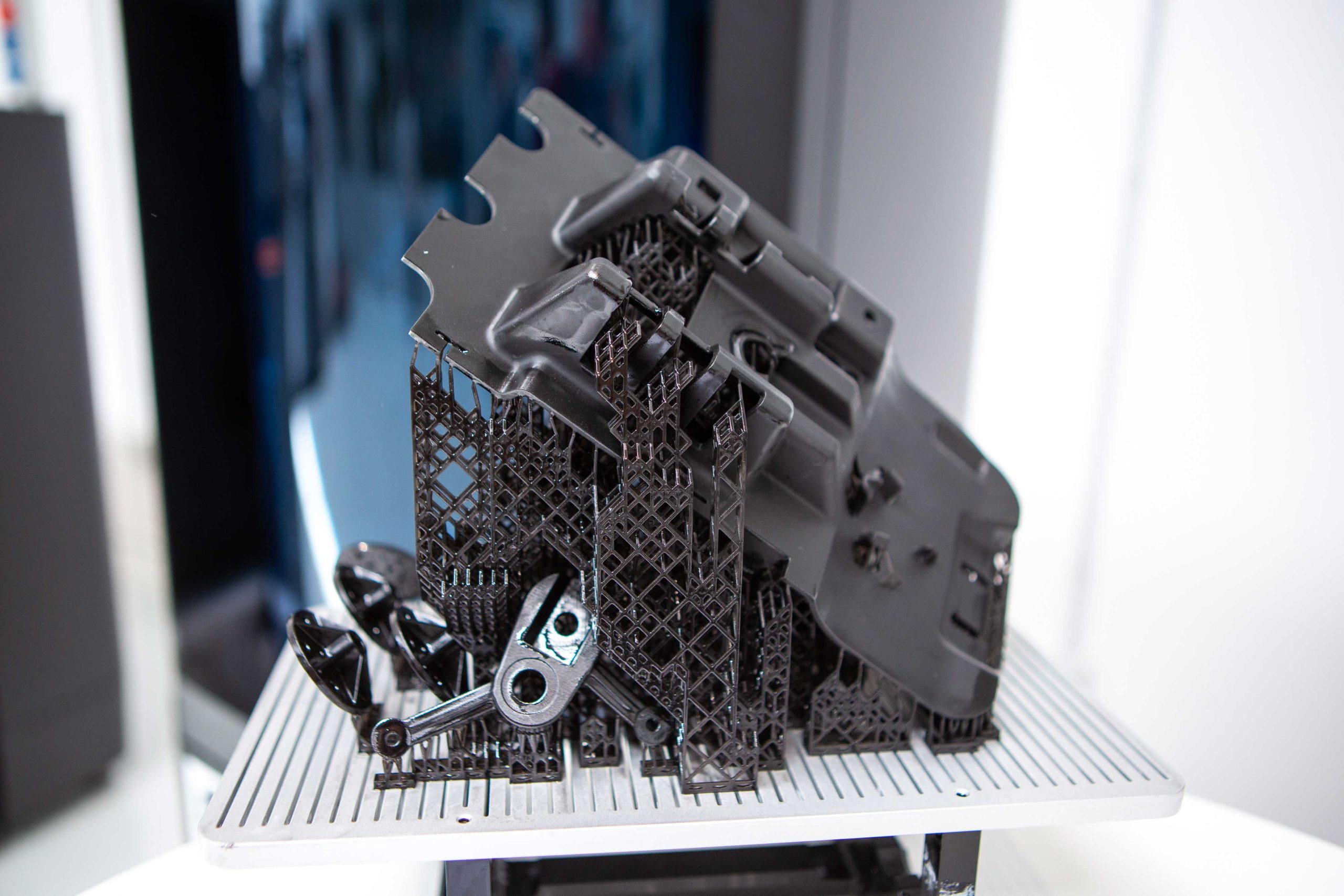

High productivity and yield optimized for fast "parts-in-hand" delivery: same-day functional prototyping and small batch production (up to 500 parts/month) with very high print speed (up to 100 mm/hour).

Versatile

Wide variety of processed materials and maximum flexibility of applications: from rapid interaction to functional prototyping, printing of parts and finished parts, and industrial production of small batches.

Efficient

Equipped with DLP technology with non-contact membrane, it offers quality and precision results with Six Sigma repeatability, excellent surface finish and detail accuracy.

Simple

Facilitates and supports every step-from file processing with intuitive 3D Sprint® software to manual material feeding and separate post-processing units available for curing.

Modular

Supplied in configurable units for complete production scalability: from a stand-alone printer for prototyping and low-volume production to a fully automated and integrated industrial solution.

Contact us to get more information and to request a quote