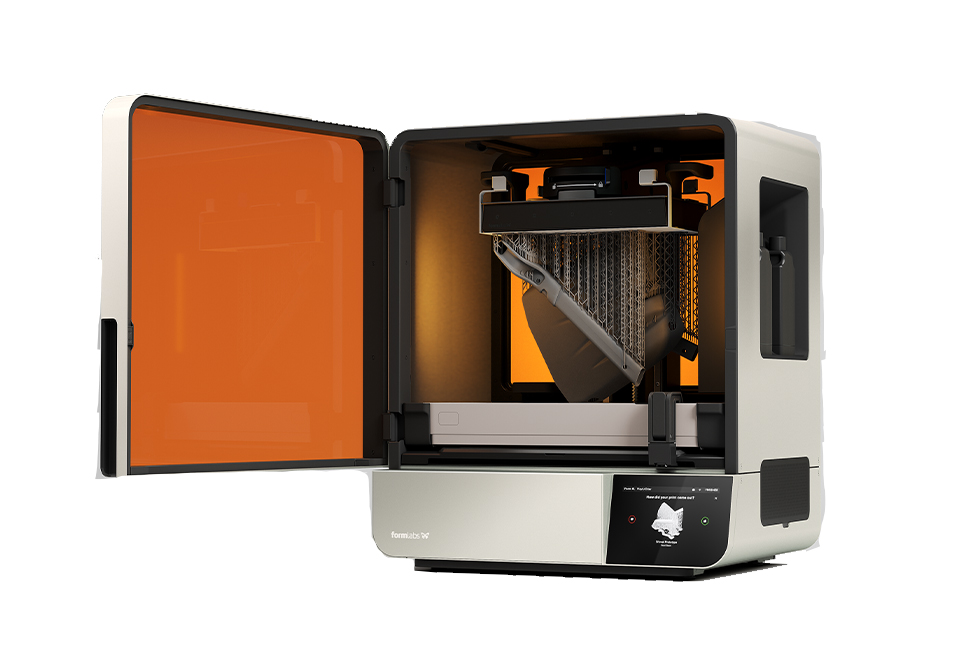

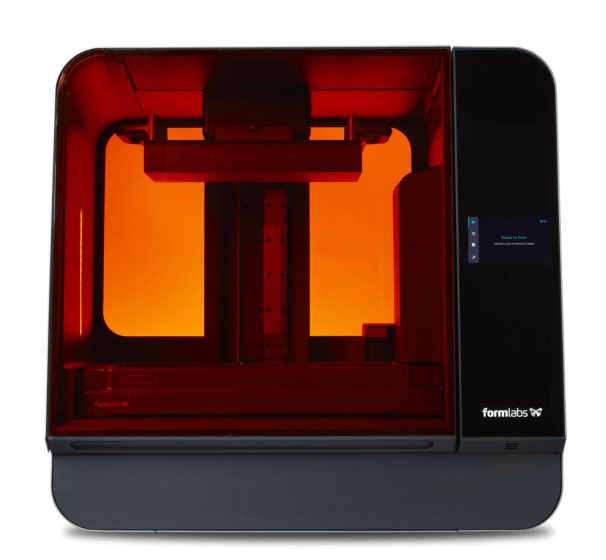

Form 4L

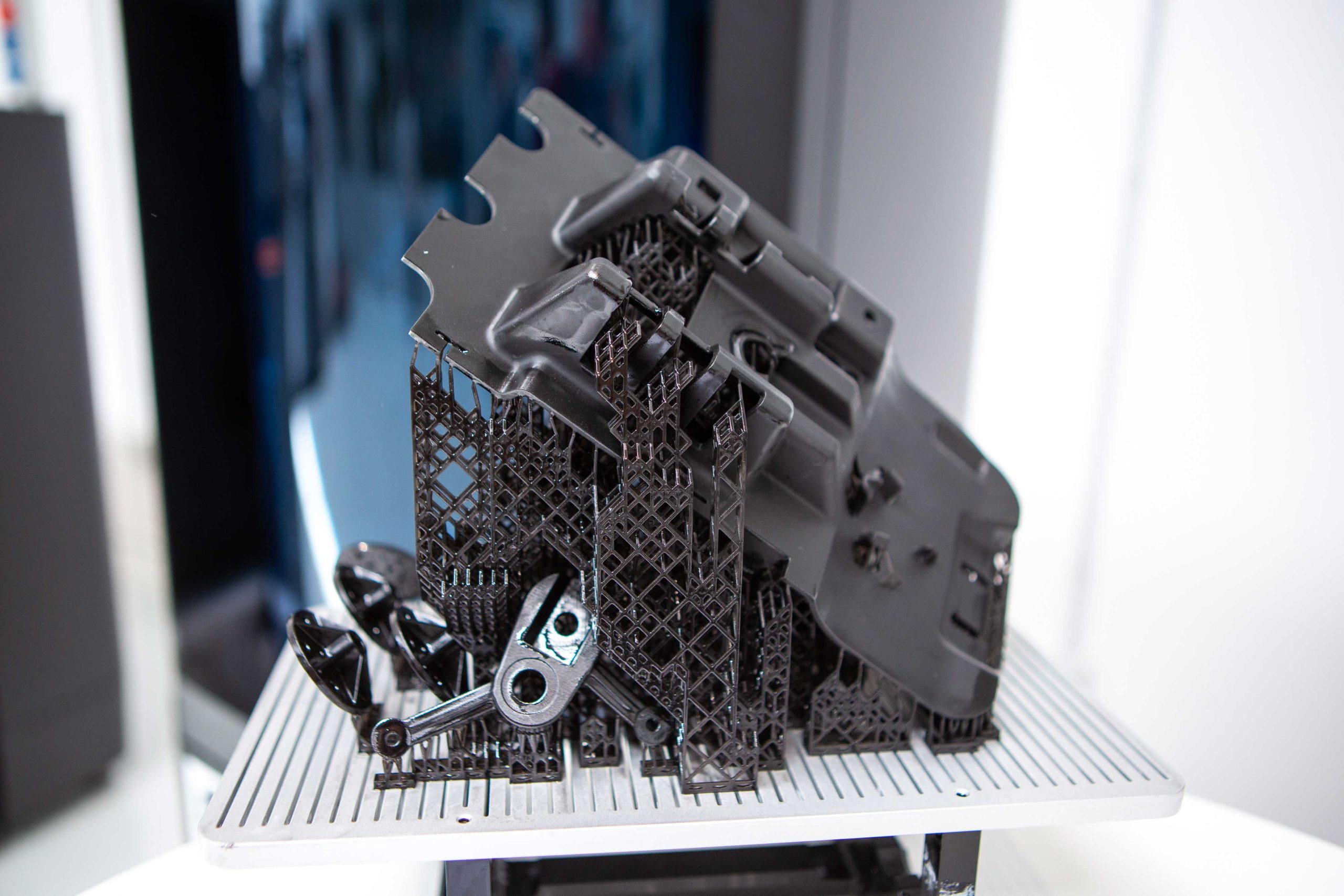

SLA's superfast large-format 3D printer

The Form 4L is an ultra-fast 3D printer for making industrial-quality large-format parts. The Form 4L offers nearly five times the print volume of the Form 4 and is up to five times faster than the Form 3L. It features mSLA technology and is reliable and accurate. It has a wide range of other performance resins and also allows third-party resins to be printed.

- Print volume

- 35.3 × 19.6× 35 cm

- Resolution XY

- 46 μm

- Layer thickness

- 25 – 200 μm

- Laser power

- 16 mW/cm2

Black Resin V5

Black Resin V5 is a versatile 3D printing resin formulated for use with the new Form 4L ecosystem. This material offers the perfect balance of print speed, high accuracy, presentation-ready appearance, durability, and a simple and reliable workflow.

Applications:

Prototypes for validation and assembly

Presentation-ready models with precise and intricate details

Cases and housings

Templates and fasteners

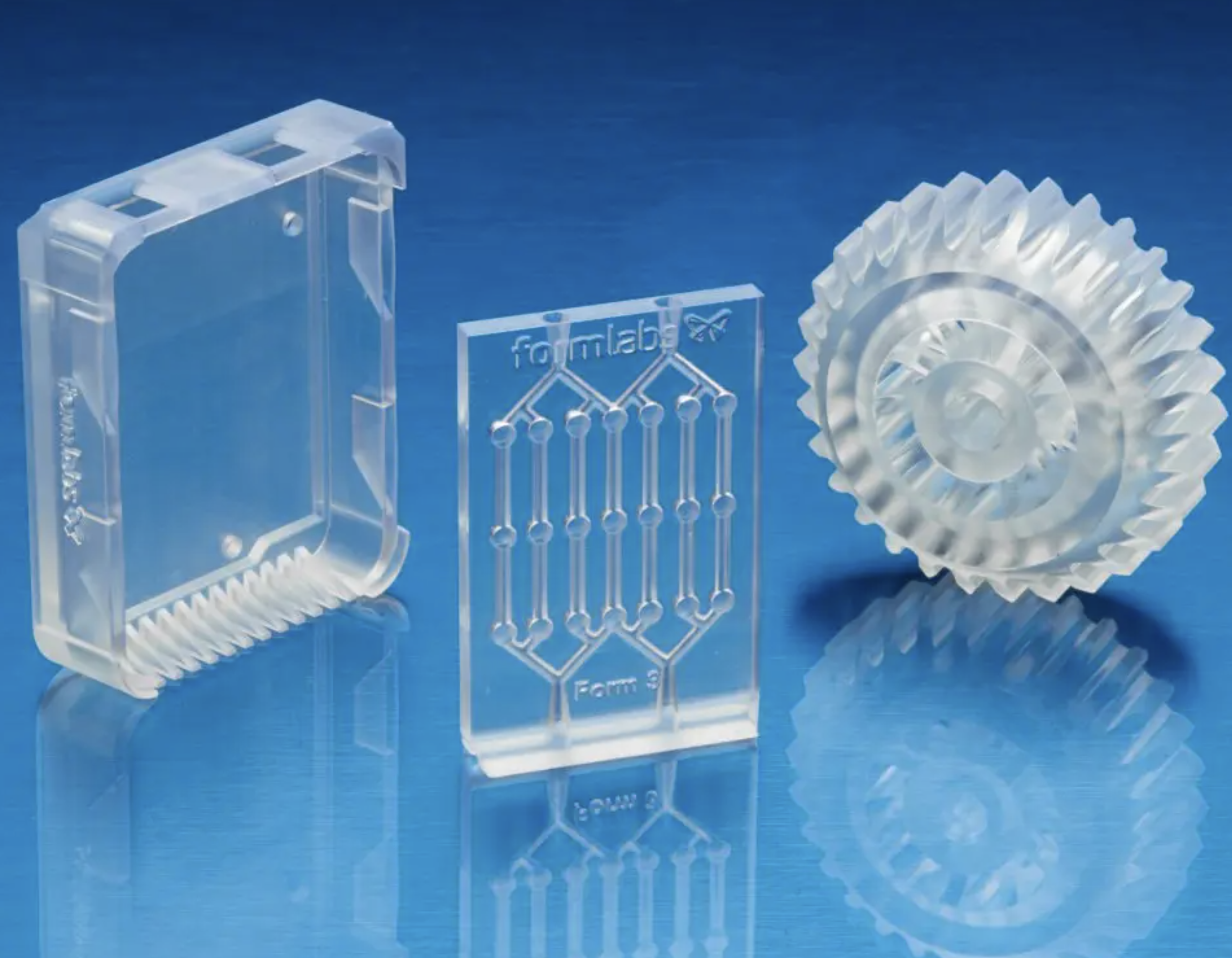

Clear Resin V5

Clear Resin V5 is a resin for 3D printing parts with neutral color and extraordinary transparency, formulated for use with the new Form 4L ecosystem. This material offers a perfect balance of print speed, high accuracy, transparency, remarkable mechanical properties, and a simple and reliable workflow.

Applications:

Transparent housings, optical components, and prototype lighting elements

Parts with visible internal details

Rapidly created molds, masters and other equipment

Fluidic devices

Fast Model Resin

Fast Model Resin is Formlabs' fastest resin, capable of printing over 80 mm per hour. It prints dental models in minutes or large prototypes in less than two hours.

Fast Model Resin is the next generation of Draft Resin for the Form 4L series that allows you to print three times faster while offering improved mechanical properties.

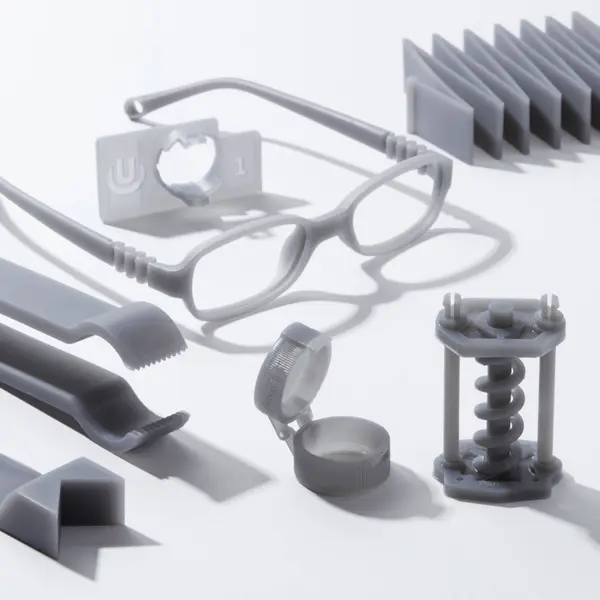

Grey Resin v5

Grey Resin is an extraordinarily versatile general-purpose standard resin that offers the perfect balance of print speed, high precision, presentation-ready appearance, rigidity, and a simple, reliable workflow. It creates rigid, durable parts with a surface finish comparable to that achieved by injection molding. Grey Resin has an intense matte color that can accurately reproduce even the most intricate details.

Grey Resin V5 is a new formulation for the Form 4 series that allows it to mold three times faster than the previous version while offering improved mechanical properties.

White Resin V5

White Resin V5 is a standard general-purpose resin with an exceptionally bright white color that offers the perfect balance of print speed, high precision, surface quality, stiffness, and a simple, reliable workflow.

It creates rigid, strong parts with a surface finish comparable to that achieved by injection molding. White Resin has a bright, opaque color that can accurately reproduce even the most intricate details.

White Resin V5 is a new formulation for the Form 4L ecosystem that enables printing three times faster than the previous version.

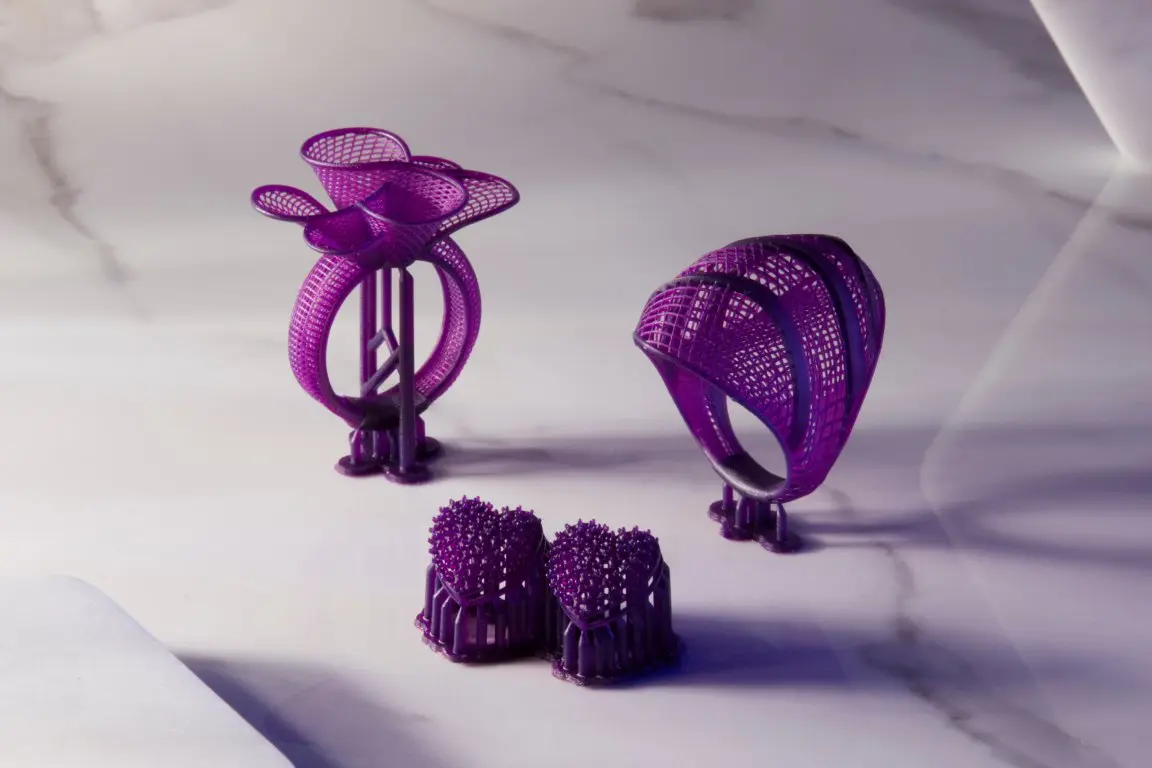

Castable Wax Resin

With a wax content of 20 percent, Castable Wax Resin enables the rendering of elaborate details and offers a smooth surface finish for precise castings with zero ash and clean burning. It is ideal for producing very fine structures in jewelry, as well as extremely accurate patterns for casting and molding dentures.

Dentistry: Castable Wax Resin enables the production of extremely accurate patterns for casting and molding dental prostheses. Extensively tested in dentistry, this resin simplifies the creation of 3D printed models for copings, internal frameworks, full contour crowns and skeletons.

Jewelry: Castable Wax Resin offers high stiffness and strength, enabling extremely thin structures to be printed. The material's high strength in its raw state ensures excellent shape retention for thin models such as filigrees.

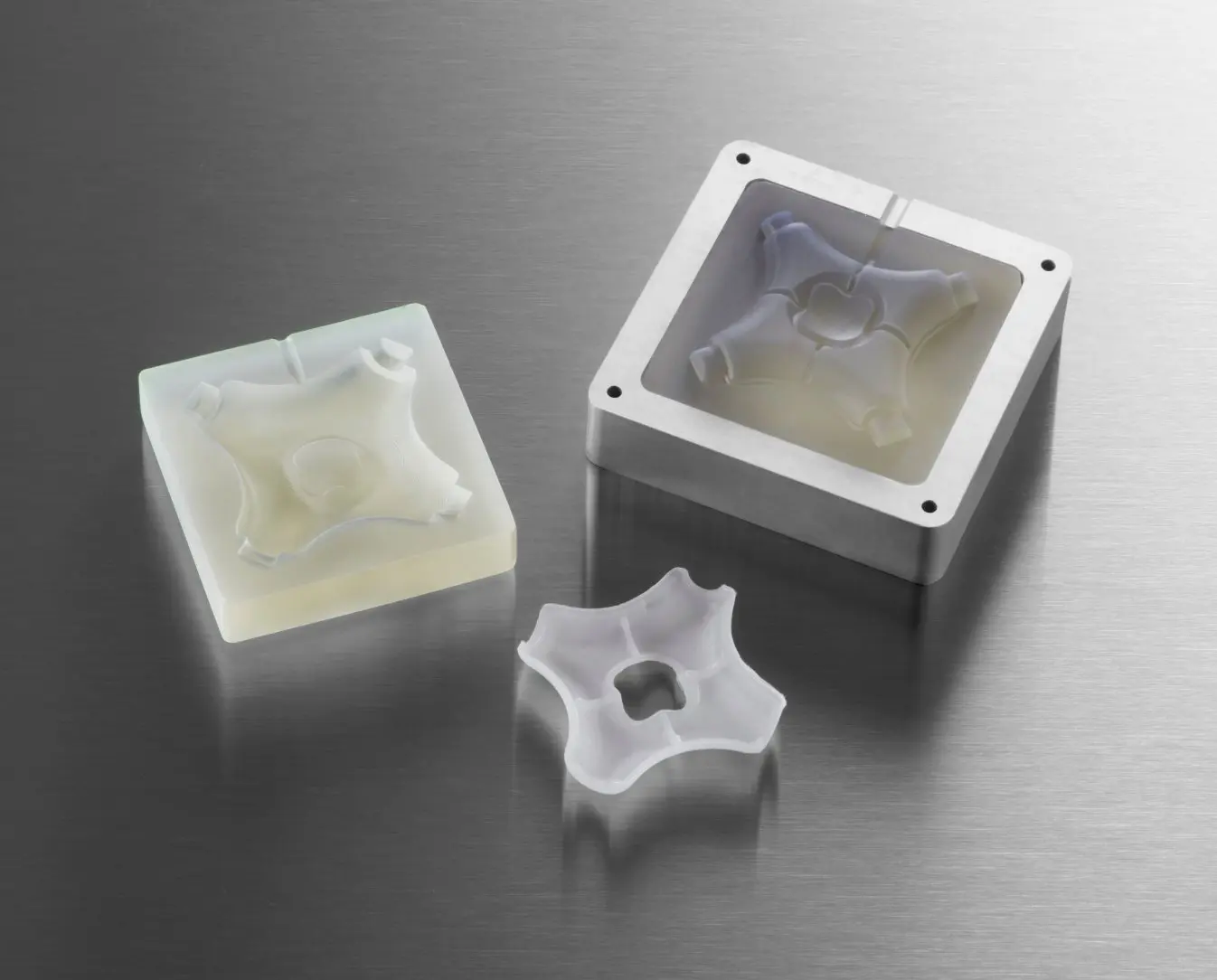

Clear Cast Resin

Clear Cast Resin is a material designed for lost-wax casting, which allows models to be directly molded for coating and casting. It features extremely low thermal expansion, low ash residue and total absence of heavy metals.

In combination with crosslinking software, this resin is ideal for creating large parts and offers outstanding results in creating geometries over 3 mm thick.

Color Base

The Color Base is the first integrated color mixing solution for resin 3D printing. It allows 3D printing in a wide range of colors without having to perform manual steps such as finishing and painting.

Color Base Resin is the base to which the pigments included in the Color Kit can be added to create Color Resin. Purchase the Color Base Resin and add the pigments included in the Color Kit to create your own colored resin.

Durable Resin

Durable Resin is a flexible, impact-resistant and smooth material suitable for making compressible parts and low-friction assemblies. Parts molded with Durable Resin are strong and have reduced friction, with similar strength and stiffness to polyethylene (PE) and a coefficient of friction comparable to that of Delrin® (POM).

Applications:

Compressible prototypes

Low-friction assemblies

Ropes and fasteners subject to significant impact

Elastic 50A

Elastic 50A Resin is an elastomeric, soft, translucent material with Shore 50A hardness and is ideal for prototyping parts normally made with softer rubbers and silicones.

Parts molded with Elastic 50A Resin can be bent, pulled and compressed, can withstand repeated cycles without tearing, and quickly recover their original shape.

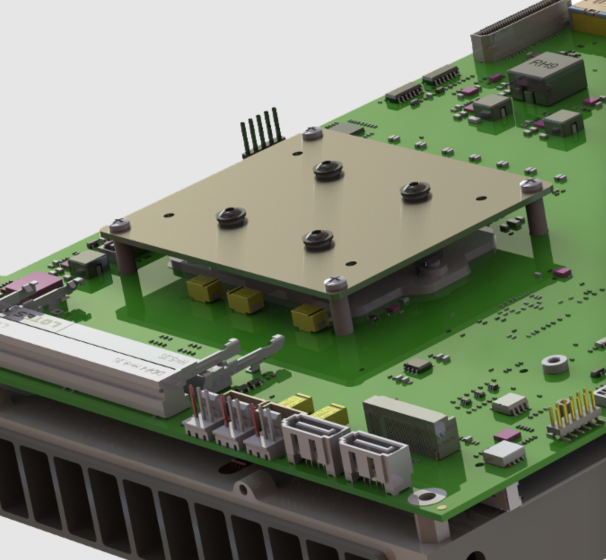

ESD Resin

ESD Resin is a specialized material for making electrostatically safe prototypes and custom manufacturing equipment to increase operational efficiency and improve the performance of electronic component production lines. Parts molded with ESD Resin can dissipate static electricity and have a high modulus and impact resistance similar to ABS.

Applications:

Prototyping and workflow validation for electronic component manufacturing,

Printing of parts that can dissipate static electricity and are dustproof,

Housings to protect sensitive electronic components from electrostatic discharge.

Flame Retardant Resin

Flame Retardant Resin is a specialized UL 94 Blue Card certified material for creating self-extinguishing parts with optimal performance against flame, smoke and toxicity. For printing flame retardant, rigid, heat- and creep-resistant parts that offer exceptional long-term performance in indoor and industrial environments with high temperatures or ignition sources.

Tests and certifications include: UL 94 V-0 with 3 mm thickness for flammability; FAR 25.853 Appendix F, Part I for flammability; ASTM E662 for ratings against flame, smoke and toxicity.

Flexible 80A

Flexible 80A Resin is a rigid, soft-touch, translucent elastomer with Shore 80A hardness, ideal for prototyping rubber-like parts with the flexibility of hard rubber or TPU.

Parts molded with Flexible 80A Resin can withstand repeated bending, flexing and compression cycles.

High Temp Resin

High Temp Resin has a heat distortion temperature of 238 °C at 0.45 MPa, the highest among Formlabs resins.

Applications:

Accurate and richly detailed prototypes and end-use parts that require high thermal stability

Molds and inserts, parts exposed to flows of hot air, gases and fluids,

Heat-resistant attachments, housings and fasteners.

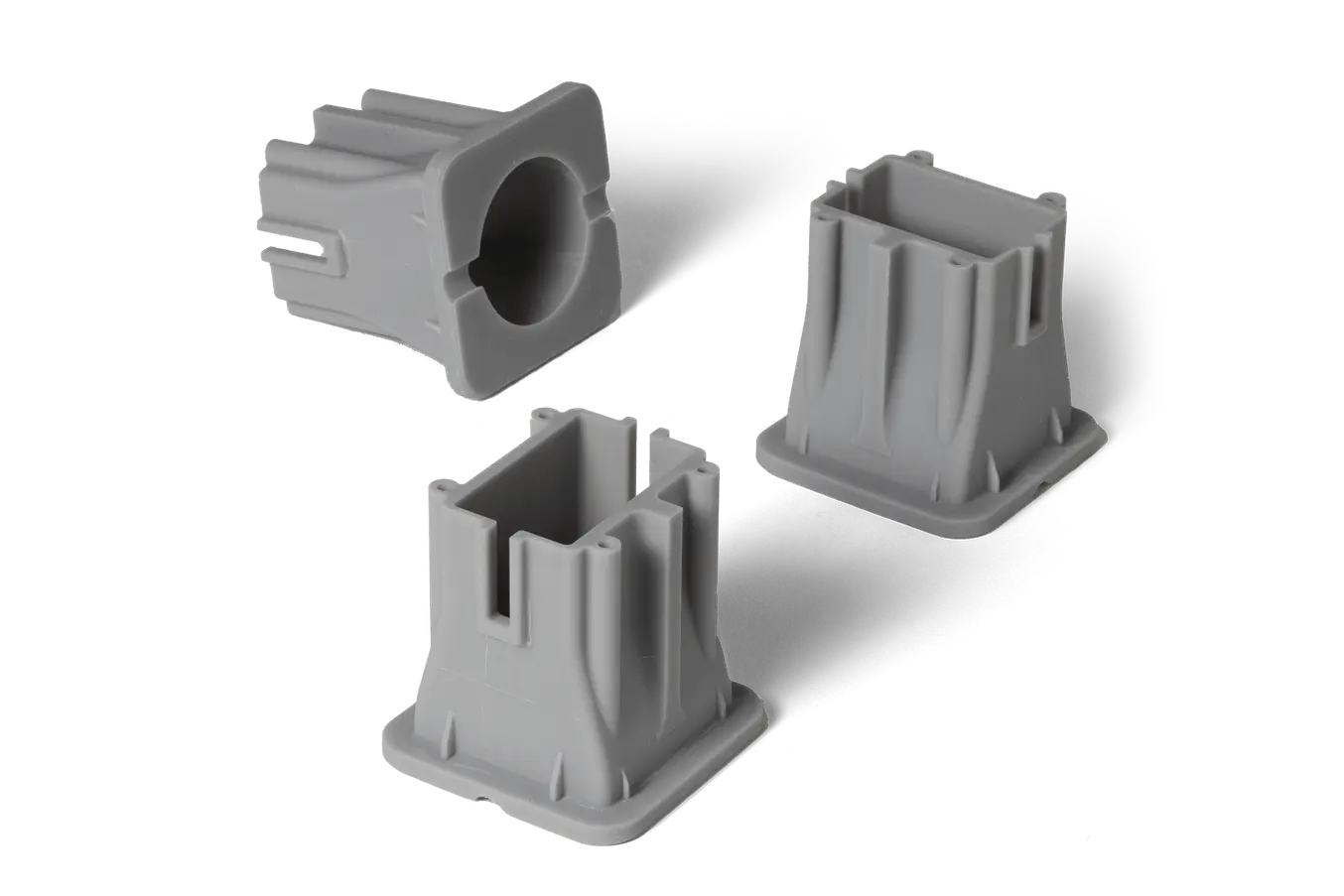

Rigid 10K Resin

Rigid 10K Resin is an extremely rigid glass-reinforced material similar to glass and fiber-reinforced thermoplastics. It prints with a smooth, matte and glossy surface finish and high resistance to heat and chemicals.

Applications:

Precise industrial parts such as molds, jigs, impressions, and other equipment for processes such as injection molding, thermoforming, or blow molding,

Functional prototypes and end-use parts requiring dimensional accuracy and stability at high pressures and temperatures.

Rigid 4000

Rigid 4000 Resin is a precise glass-reinforced resin that offers similar stiffness to PEEK and PEKK thermoplastics. It prints with a smooth, matte and glossy surface finish and high resistance to heat and chemicals.

Applications:

Rigid and tough prototypes for engineering use,

General applications capable of supporting heavy loads

Industrial parts that must support heavy loads without bending.

Tough 1500

Tough 1500 Resin is a resilient, skin-contact safe material that offers similar strength and stiffness to polypropylene (PP).

Tough 1500 Resin is certified as safe for skin contact, which also makes it the ideal material for wearables, personal protective equipment, and other consumer goods. For parts to be certified as safe for skin contact, the recommended Tough 1500 Resin post-processing directions should be followed without deviation.

Applications:

Rigid and flexible parts and prototypes that quickly bend and return to their original shape

Files and fasteners that require repeated distortion.

Tough 2000

Tough 2000 Resin offers similar strength and stiffness to ABS, properties that make it ideal for difficult-to-bend functional parts that can withstand extended use.

Applications:

Prototyping strong and durable parts that do not have to bend easily

Files and fasteners that require minimal distortion.

Prototyping

Verify and optimize your design to achieve a product that is perfect in every aspect. 3D printing enables extremely fast, easy and cost-effective production of high-quality prototypes, which are essential for experimenting with alternatives or verifying every functional, aesthetic and design aspect, avoiding slowdowns and errors.

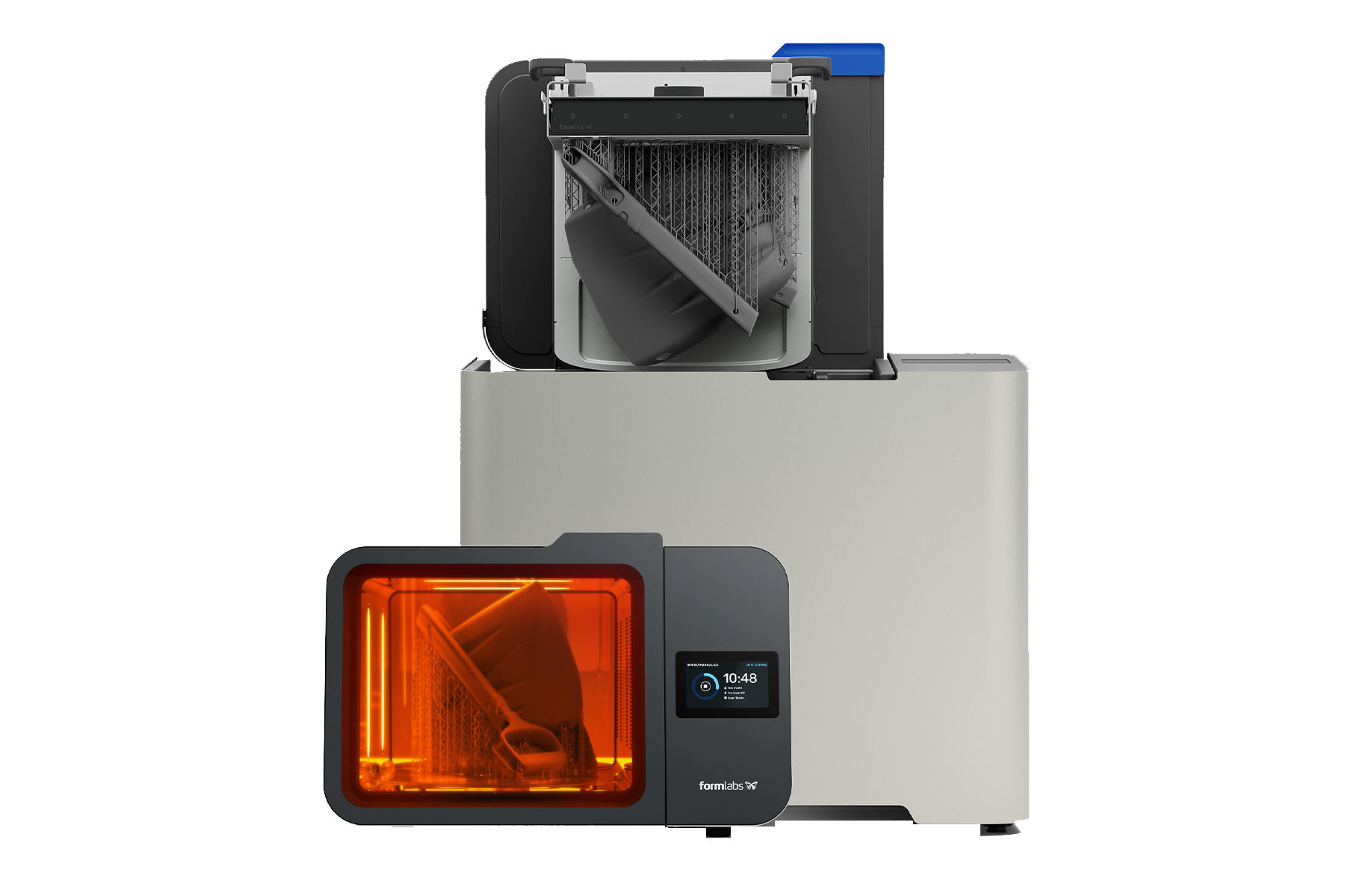

Form Wash L & Form Cure L

The Form Wash L agitates the solvent to remove resin residue from 3D printed parts by stereolithography, allowing you to achieve smooth, clean, high-quality parts every time. Once the wash is complete, the parts are removed from the solvent and air-dried to prevent the prints from becoming soaked with solvent or warping.

Form Cure L uses heat, UV light, and uniform exposure to enable parts to achieve optimal mechanical properties and dimensional accuracy.

Optimizes printing processes in PreForm

Design your model in standard CAD software and import it into our PreForm print preparation software in STL or OBJ format. Prepare your model in minutes, load it on the printer, and start printing.

Form 4L a complete SLA ecosystem

Print large-format parts at lightning speed with Form 4L. Powered by Formlabs' state-of-the-art Low Force Display™ print engine, Form 4L delivers outstanding speed, reliability, and print quality for prototype and end-use parts production.

Extraordinary part quality and uniform surfaces

You won't have to sacrifice quality to achieve large prints.

Form 4L allows you to create parts with the smooth surface finish and fine details that stereolithographic 3D printing is known for.

With low release forces and lightweight, easily removable substrates, surfaces are uniform with a finish on par with injection molding.

Intuitive and efficient

There is no need to hire specialized technicians. Anyone can learn how to use it in 15 minutes.

Form 4L offers validated print settings , has very intuitive print preparation software and allows you to monitor printing remotely.

With Form 4L, you can customize performance exactly to the part being printed, using editable and shareable print settings.

A resin for every application

Form 4L has a wide range of high-performance materials: from those optimized for impact resistance, stiffness, flame resistance, flexibility, and more.

Materials such as pure silicone, ceramic, and polyurethane are also found for Form 4L in the range.

Given its compatibility with more than 23 Formlabs materials and the ability to use third-party materials with the Open Material Mode, it is the ideal solution for versatile, high-throughput printing.

Plus, with the Resin Pump and 5-liter resin packs, you can print without interruption and increase your productivity.

Simple and effective post-processing

Form 4L's Build Platform features a durable aluminum surface. A replacement Build Platform allows you to speed up your workflow and print without interruption when you need to change resin or start a new parallel print.

You can further speed up your workflow by choosing the Build Plaform Flex accessory, which, with its patented Quick Release Technology, allows you to remove parts from the print platform in seconds, without using any tools. Make the post-processing workflow smoother by removing finished parts quickly and accurately.

They complete the Form Wash and Form Cure ecosystem.

Extremely sharp details

Highly collimated light with pre-tuned anti-aliasing for subpixel resolution.

More precise assemblies: XY dimensional tolerances of ±0.15% to ensure proper assemblies every time.

Possible applications

Form 4L can find application for:

Large-scale prototypes

Fit/form testing

Casting patterns

Templates and poses

Medical device prototypes

Medical/anatomical models

Orthoses

Contact us to get more information and request a quote