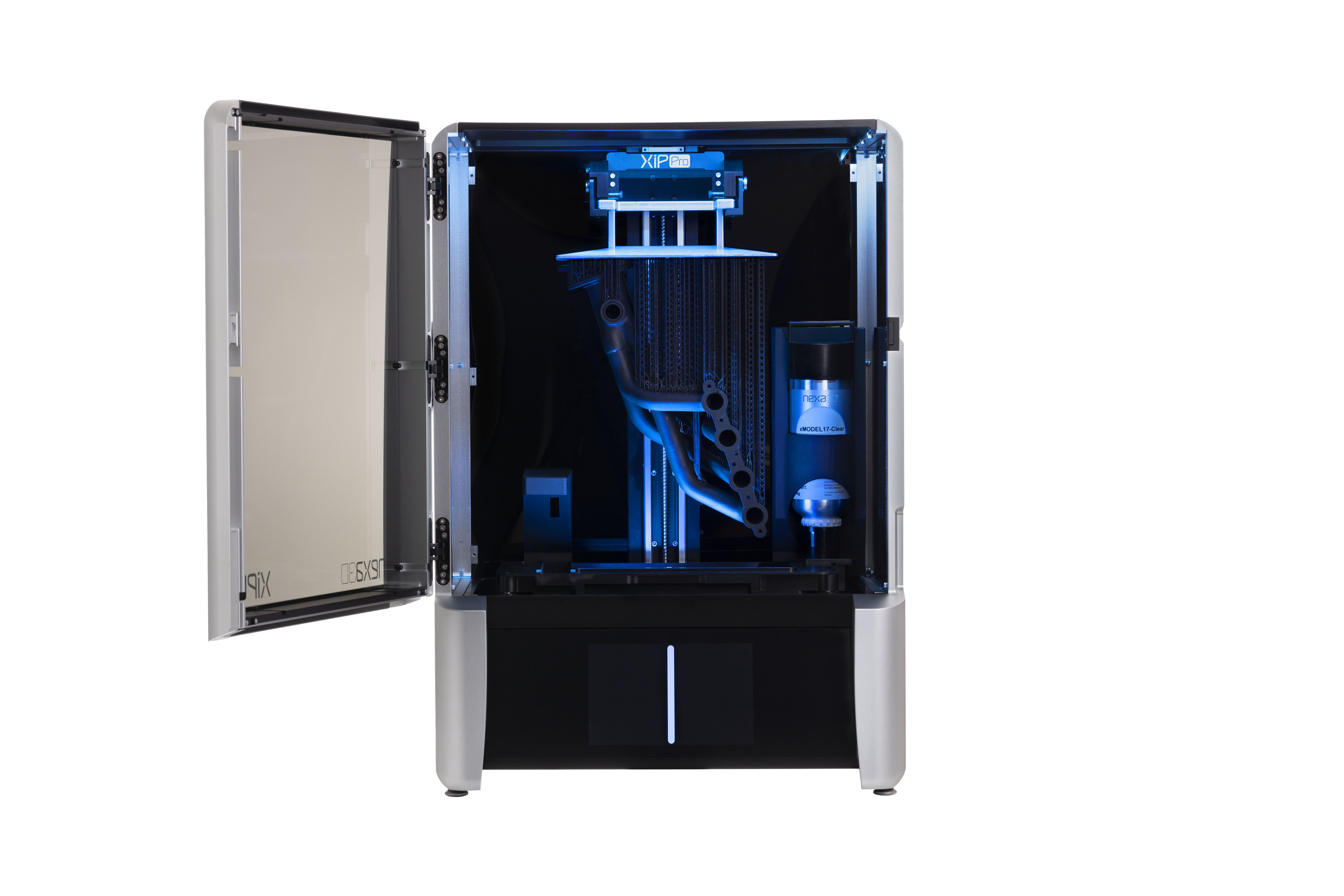

Xip Pro

The fastest and highest resolution resin 3D printer for end-use parts

XiP Pro is an industrial resin 3D printer that offers maximum productivity at the lowest operating cost. 1. High speed 2. High working volume 3. High surface quality 4. Wide range of materials

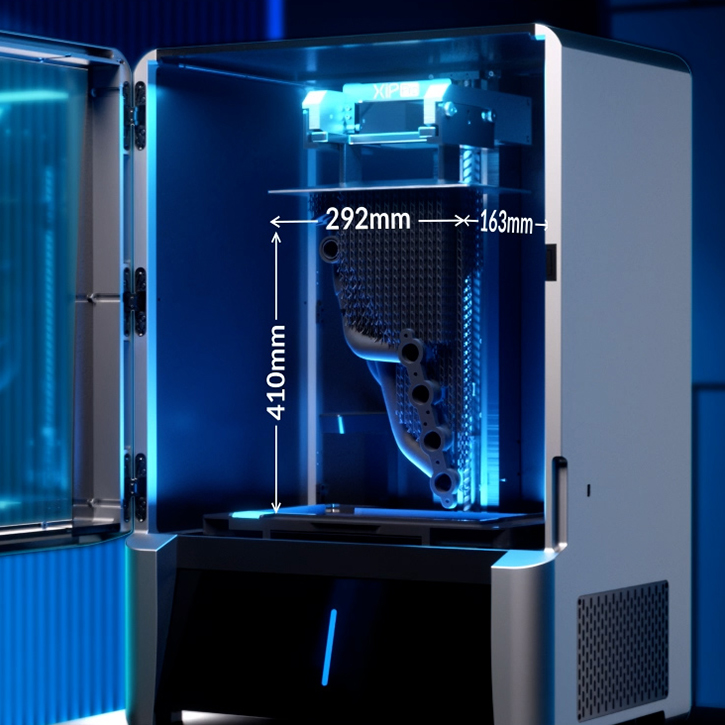

- Volumen de impresión

- 292 x 163 x 410 mm

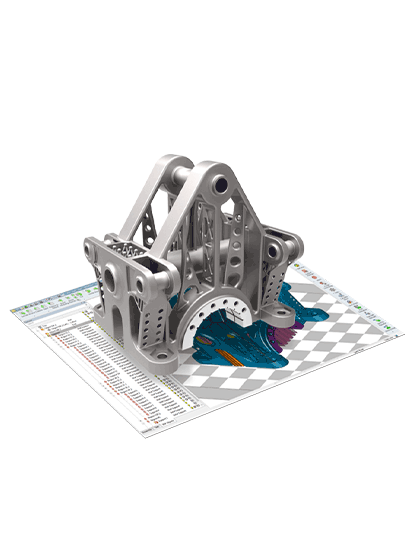

- Software

- NexaXPro

- Sistema abierto

- SI

xABS3843

Strong and durable material with the look of black injection-molded ABS.

A high-performance, high-modulus material that boasts excellent flexural and tensile physical properties with a relatively high degree of elongation. It has high green strength and good flame deflection temperature, enabling it to mold accurately and be used in a wide range of applications. It has been tested under outdoor QUV (ASTM G-154) weathering conditions for 800 hours with less than 15 percent change in tensile and IZOD impact properties.

Features

- ABS-like stiffness

- Strong and durable

- High level of detail

Use

- Design verification models - Functional prototypes

- Snap-on assembly

- Templates and fixtures

- Templates

- End-use parts

- Good weathering performance

Manufacturing partners

Henkel

xCE-Black

High-rigidity, temperature-resistant material with the aesthetic and environmental longevity characteristics of injection-molded nylon, polyester, polyamides, and polyimides. xCE is proven for the production of parts exposed to sun, moisture and heat.

Features

- High stiffness of plastic - High temperature

- Durable, chemical resistant

Use

- Functional prototypes subjected to higher temperature testing

- Low-volume injection molding inserts for low-temperature plastics

- End-use parts

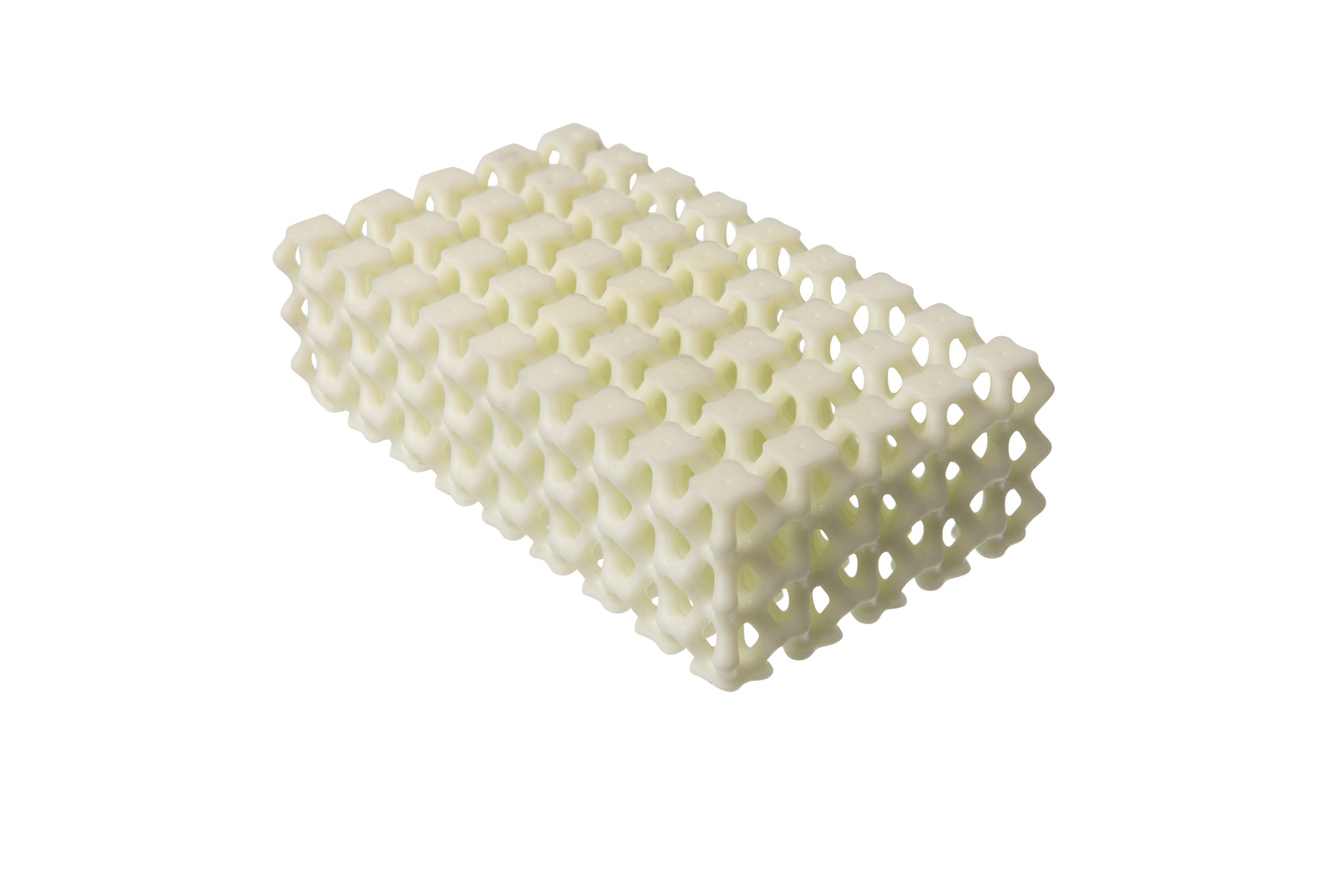

xCERAMIC3280

xCERAMIC3280 is a ceramic composite resin for rigid parts with a high flame deflection temperature and excellent tensile modulus at some of the highest speed of any material class. The new xCERAMIC3280 resin is the perfect choice for tooling applications, wind tunnel test models, and products that require a ceramic appearance and finish.

Features

- High heat deflection - High-speed printing

- Very high stiffness

- Ceramic look and feel

Uses

- Equipment

- Wind tunnel models

Production partners

BASF Forward AM

xFLEX402-Black

xFLEX402 is a flexible black material with shore 76A durometer, high elongation at break and excellent tensile strength, ideal for functional prototyping applications of elastomeric components and production parts.

Features

- Compact rubber type

- High elongation at break

Use

- Functional prototyping

- Rubber-like production parts

Production partners

Henkel

xFLEX475 - Black, White

A medium-soft rubber-like material that cures with a soft, elastomeric structure. Customers can use this industrial strength material in applications requiring resilience, elasticity, and tear resistance, such as pipes and manifolds, handles and grips, gaskets and seals, or midsoles of sportswear and footwear. This material also boasts an impressive elongation at break of 150%, excellent energy return of up to 50%, and resistance to most solvents.

Features

- Soft and elastic

- Single-component with low viscosity

Use

- Elastomeric resilience, snap back and tear resistance applications

Manufacturing partners

Henkel

xMODEL 15 - White, Gray

xMODEL15: an affordable modeling material that offers excellent speed, productivity and surface finish quality. For those looking for superior finishes, xMODEL15 is suitable for polishing, painting and even plating. Best of all, xMODEL15 is derived from plant-based materials, has little odor, and can be easily cleaned with water and light brushing.

Features

- Detailed details

- Smooth surface finish

- Economical

Use

- Visual models and prototypes

- Multi-iteration prototyping

xMODEL17-Clear

xMODEL17-Clear: rigid and durable modeling material with enhanced transparency, perfect for prototyping applications that require precise details and high-quality translucent or transparent surface finishes.

Features

- High optical transparency finishes

- Precise details

- Smooth surface finish

- Economical

Use

- Illumination

- Prototyping optics

xPEEK147

A stiff, heat-resistant black material with an HDT of 230°C similar to that of many PAEK thermoplastics such as PEEK. It exhibits excellent long-term stability at temperatures above 100°C, making it suitable for prototypes and end-use parts subjected to high temperatures and rapid molds for plastic molding.

Features

- High flame deflection temperature

- High stiffness with good dimensional stability

- Good surface finish

Use

- High-performance prototypes or end-use parts requiring high temperature capability and long-term thermal stability

- Tools and molds requiring good surface finish and long-term thermal stability >125°C

Manufacturing partners

Henkel

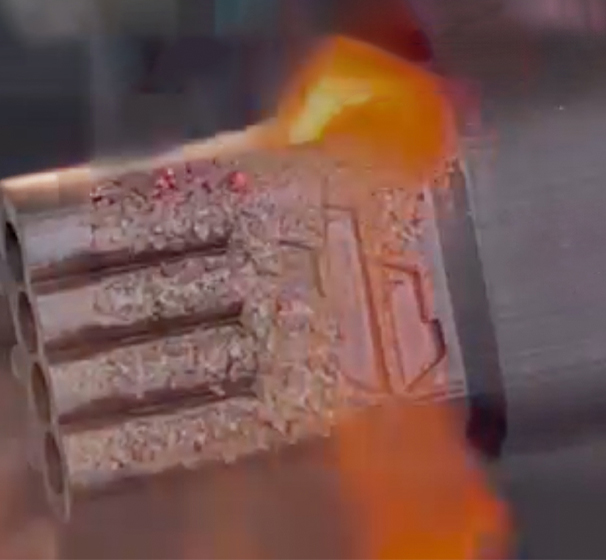

xPRO9400FR

Resin that exceeds all flame resistance requirements of the main industrial manufacturing sectors, such as automotive, railway, aerospace and electronics, among others. In addition to having excellent mechanical properties, it far exceeds the flammability requirements of the UL-94 reference standard.

It is ideal for the production of automotive, railway and aerospace parts, custom jigs and fixtures, etc. It is characterized by its low viscosity, easy processability and exceptional temperature resistance. Developed in collaboration with BASF.

xPP405-Black

xPRO410

xPRO1100-Black

It is characterized by

- Very high stiffness: with a Young's modulus of 3080 MPa.

- Very good thermal resistance: HDT up to 116°C.

- High chemical resistance: stable even in chemically aggressive environments.

- Low water absorption: 0.32% in 24 hours, maintains its dimensional stability over time.

- Long-term UV resistance.

- Ease of printing: good printing speed, fast material removal and easy wash-off due to the low viscosity of the material.

xPRO1100-Black is versatile and suitable for various applications thanks to its excellent mechanical properties.

Here are some of its main applications:

- Automotive components: connectors, brackets and housings.

- Aerospace prototypes: ideal for testing design and functionality.

- Engineering parts: components requiring high strength and stability

- Consumer products: items requiring high strength and durability

- Polyurethane molds: for rapid production of visual and functional prototypes.

XWASH

Accommodates the build volume of XiP Pro and NXE400Pro, accepting up to two build plates simultaneously for simplified post-processing workflow.

Variable-speed bidirectional agitation

Adjustable cleaning timer to optimize cleaning times based on part geometry and resin type.

Dedicated drain and fill ports for easy maintenance.

XCURE

Optimizes curing of resin-based parts and ensures consistent dimensional accuracy, solid structural integrity, and stronger molecular structures. Fits parts up to 16 liters in volume.

Can hold up to 3 build plates simultaneously

Dual-wavelength LEDs with UV and thermal treatment in parallel.

XiP Pro is an industrial resin 3D printer that offers maximum productivity at the lowest operating cost

With the highest build volume and printing speed in its class, its unparalleled productivity enables the production of functional prototypes and end-use parts at previously unattainable production costs. Its state-of-the-art, LCD-based VAT photopolymerization process using patented Lubricant Sublayer Photocuring (LSPc) technology offers high precision, excellent dimensional stability, and superb surface quality.

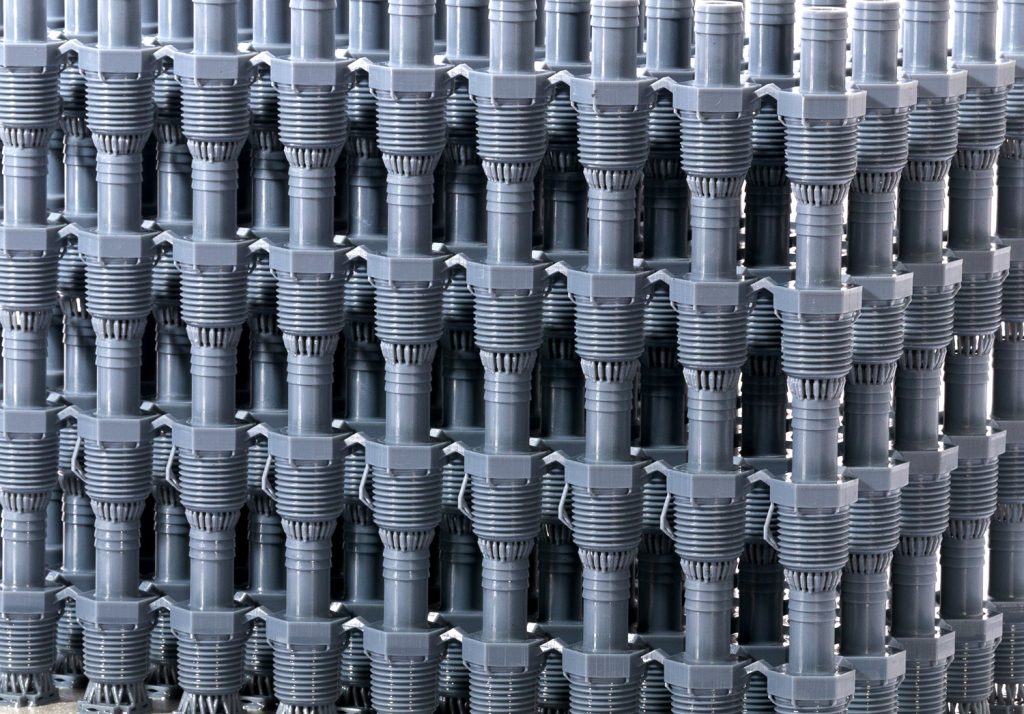

Large production volume

With a build volume of 19.5 l, XiP Pro offers daily throughput equal to that of more than 4 other resin-based industrial printers, allowing you to dramatically change the economics of your 3D printing production, as well as reduce your investment in equipment. With the ability to stack parts, you can optimize each print job by easily stacking smaller parts on top of each other to take full advantage of XiP Pro's entire production volume. From very large parts to many smaller parts, XiP Pro can do it all.

Incredible print speed

With an unmatched printing speed of up to 24 vertical centimeters per hour, XiP Pro can print the equivalent of its entire build volume in less than two hours. Its patented LCD-based LSPc printing technology uses a self-lubricating membrane that enables ultra-high printing speed and unprecedented productivity without sacrificing print quality or surface finish.

Outstanding accuracy and surface quality

XiP Pro boasts of a state-of-the-art 7K resolution LCD screen with 46 µm pixels and 23 µm sub-pixel resolution. Thanks to anti-aliasing technology, every detail of your design is captured with unparalleled sharpness and accuracy for a stunning and accurate finished product. The improved printability and outstanding first-time success rate are due to the advanced sensor package, adaptive layer-by-layer printing technology, and closed-loop z-phase with auto-homing and residue detection.

Versatility of materials

With a wide range of high-performance production materials, ranging from tough and durable resins, such as xABS, xPP, and xCE, to elastomeric materials, such as xFLEX475 and xFLEX402, XiP Pro is an open-platform printer, which means that material options are virtually unlimited. Whether building rapid models in transparent resins, prototyping functional parts in engineering materials, or producing end-use components and 3D printed molds using heat-resistant resins such as xPEEK, xCERAMIC or xMOLD, XiP Pro is the most versatile industrial 3D printer on the market.

Download

Contact us to get more information