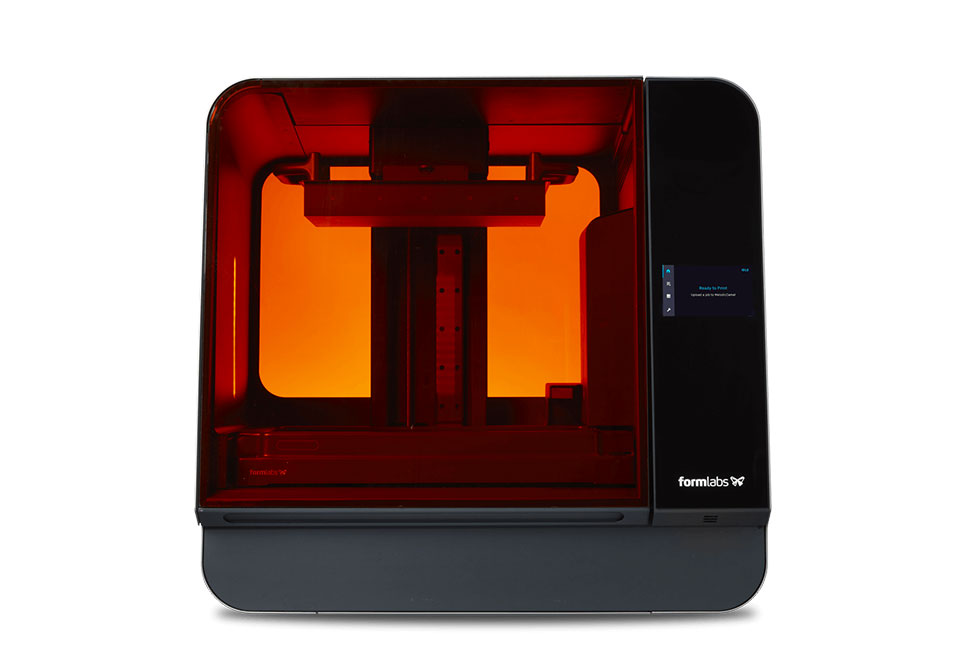

Form 3L

The desktop resin printer with a large work area

The Form 3L is an affordable large format 3D printer, chosen by professionals for fast production of industrial quality parts. With advanced Low Force Stereolithography (LFS)™ technology, Formlabs has completely revamped its resin-based 3D printing to dramatically reduce the forces in the printing process. The Form 3L offers five times the print volume and twice the laser power of Form 3.

- Print volume

- 33.5 × 20 × 30 cm

- XY Resolution

- 25 μm

- Layer thickness

- 25 – 300 μm

- Laser power

- 250 mW

Greyscale Resins

https://www.youtube.com/watch?v=dCGjaSCKqC4

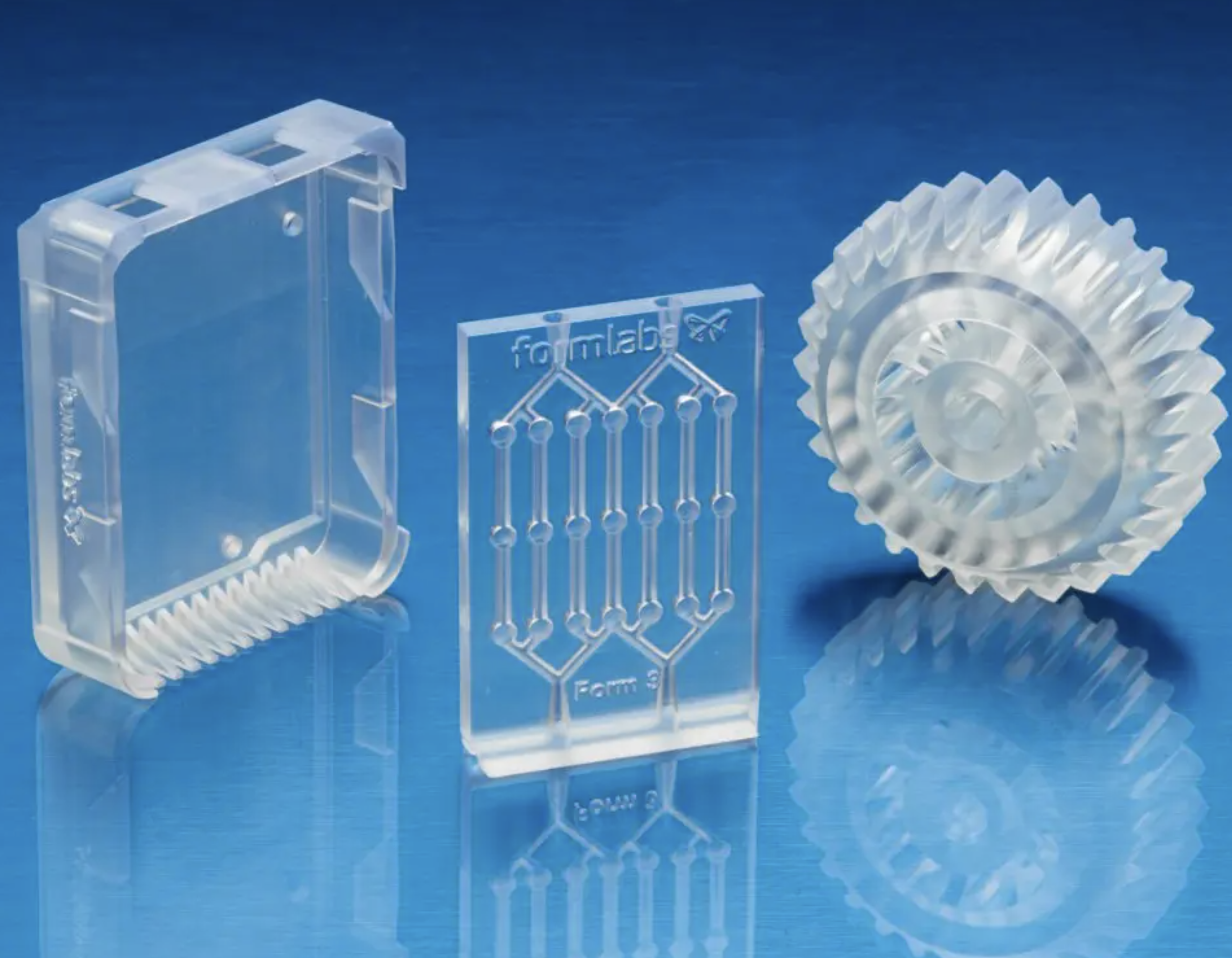

Clear Resin

Draft Resin

Color Kit

Grey Pro Resin

Rigid Resin

High Temp Resin

Flexible 80A

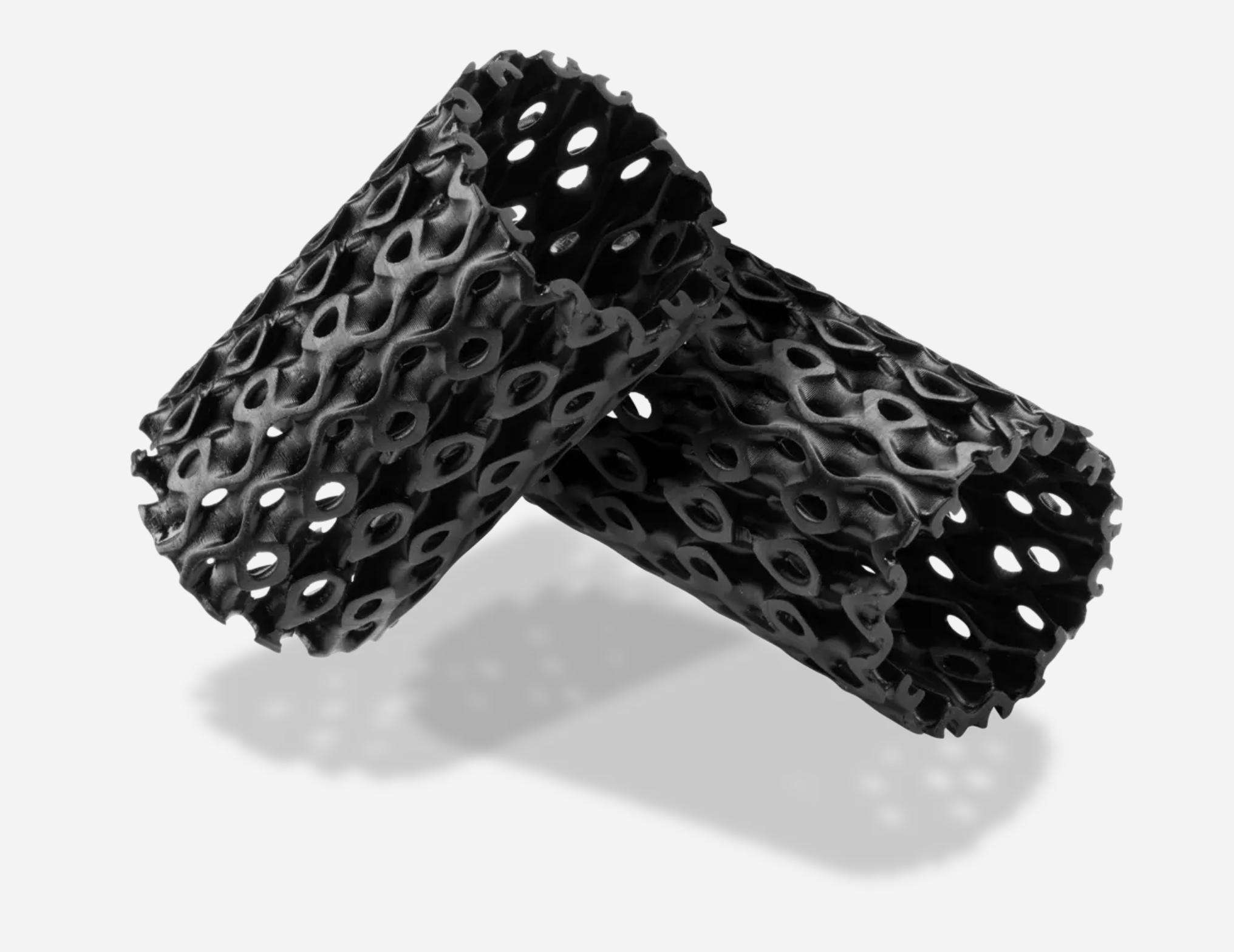

Elastic 50A

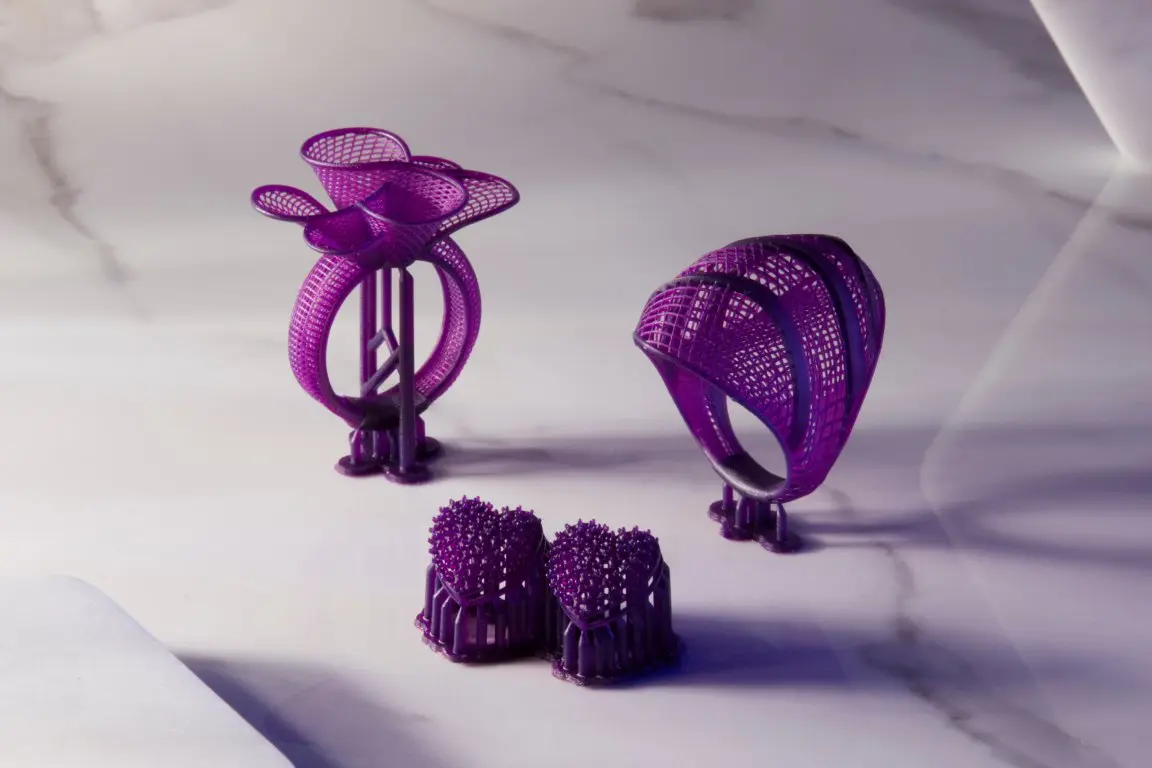

Castable Wax Resin

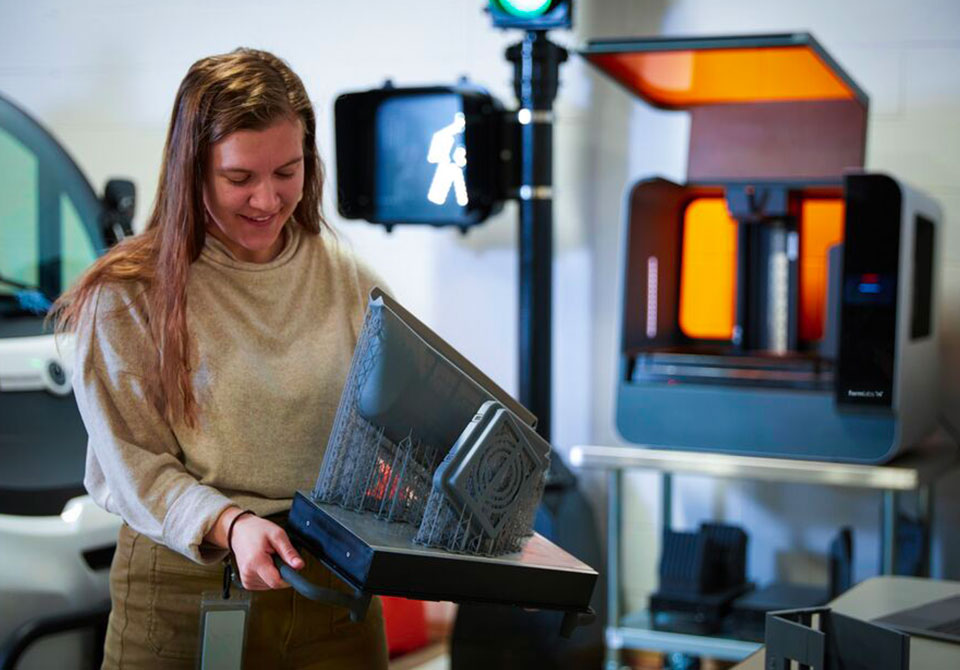

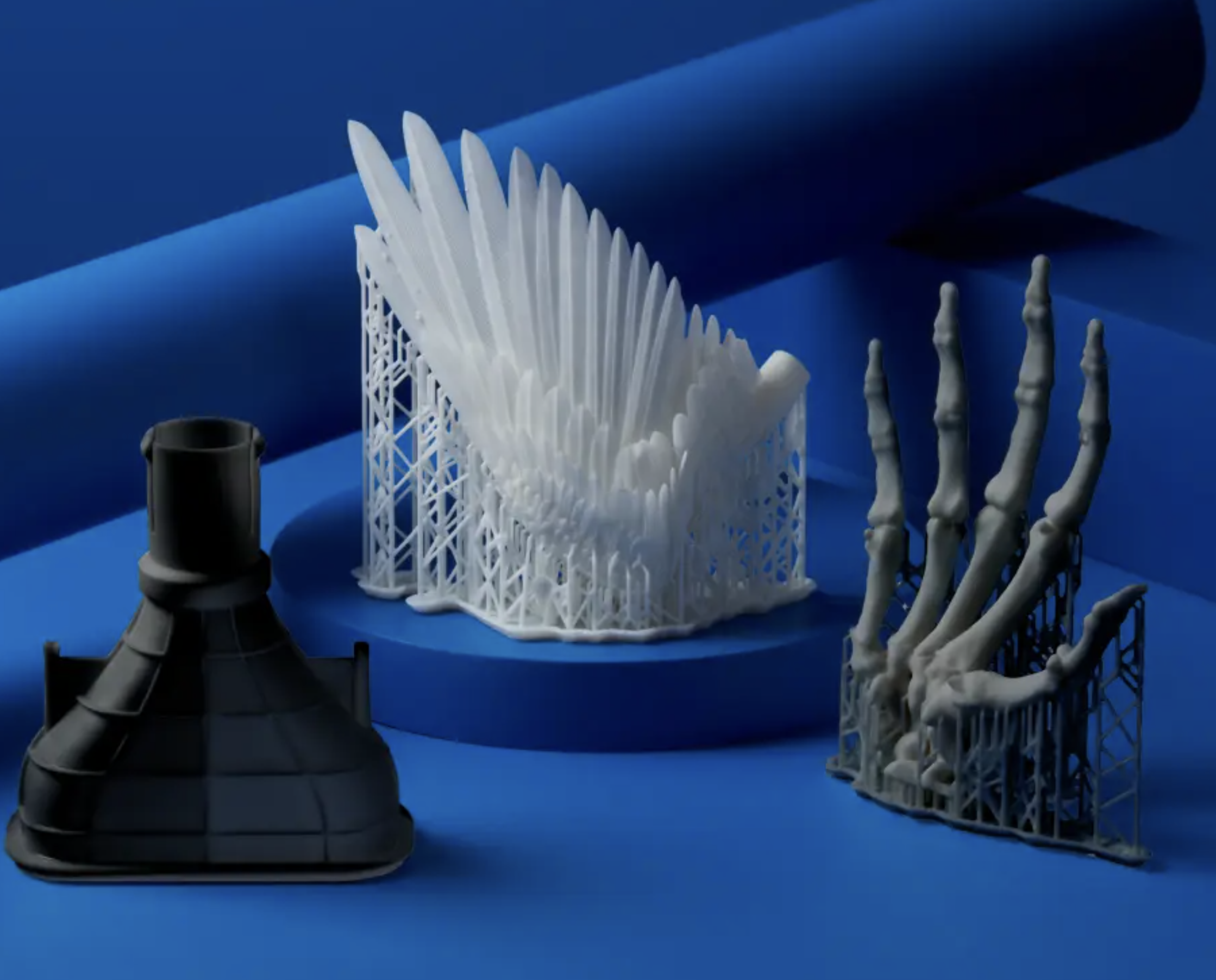

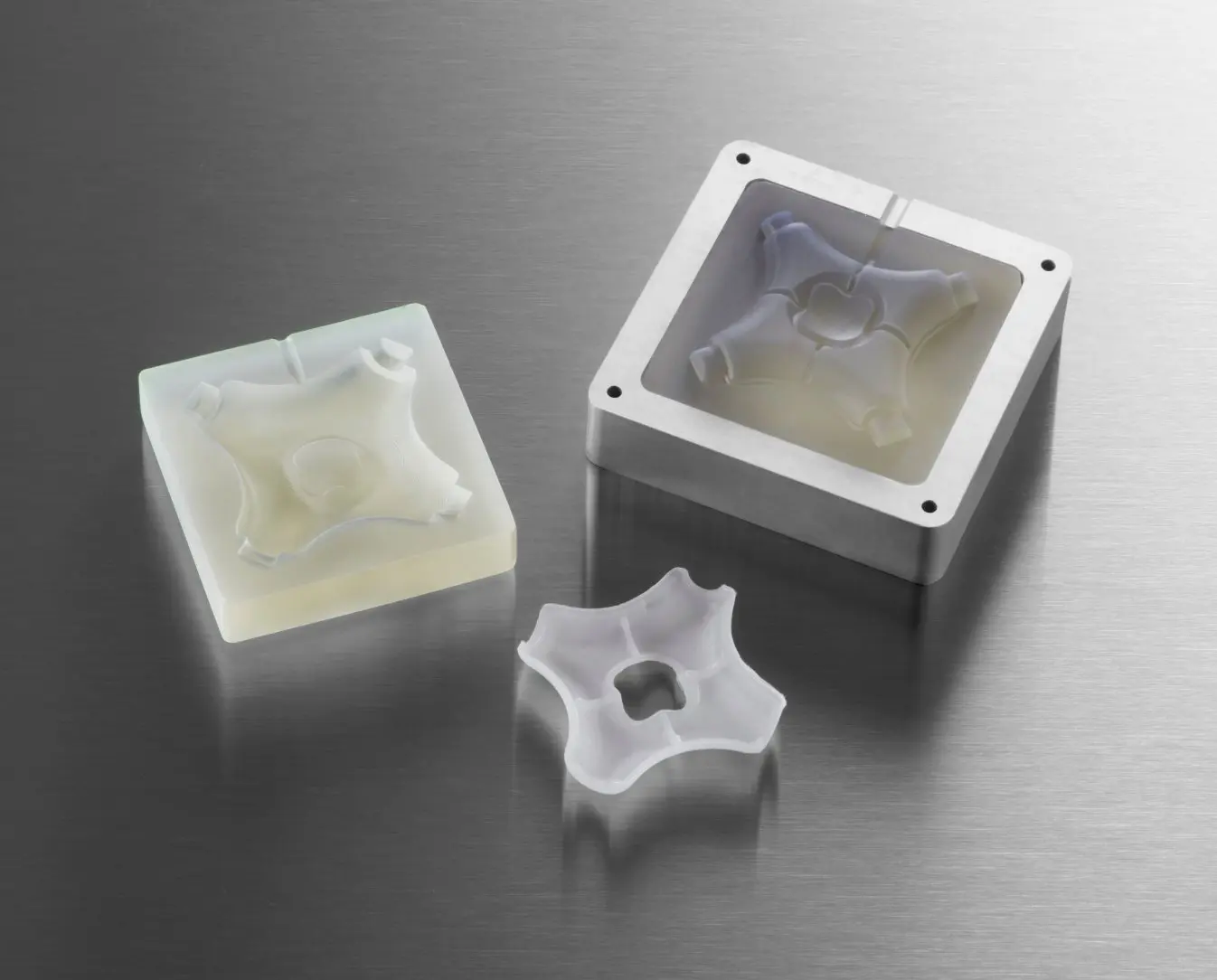

Prototyping

Verify and optimise your design for a perfect product in every respect. 3D printing makes it possible to produce high-quality prototypes extremely quickly, easily and inexpensively, which are essential for experimenting with alternatives or verifying every functional, aesthetic and design aspect, avoiding delays and errors.

Form Wash L & Form Cure L

Form Wash L

The Form Wash L agitates the solvent to remove resin residue from 3D printed parts by stereolithography, allowing you to achieve smooth, clean, high-quality parts every time. Once the wash is complete, the parts are removed from the solvent and air-dried to prevent the prints from becoming impregnated with solvent or warping.

Form Cure L

Form Cure L uses heat, UV light and uniform exposure to allow parts to achieve optimal mechanical properties and dimensional accuracy.

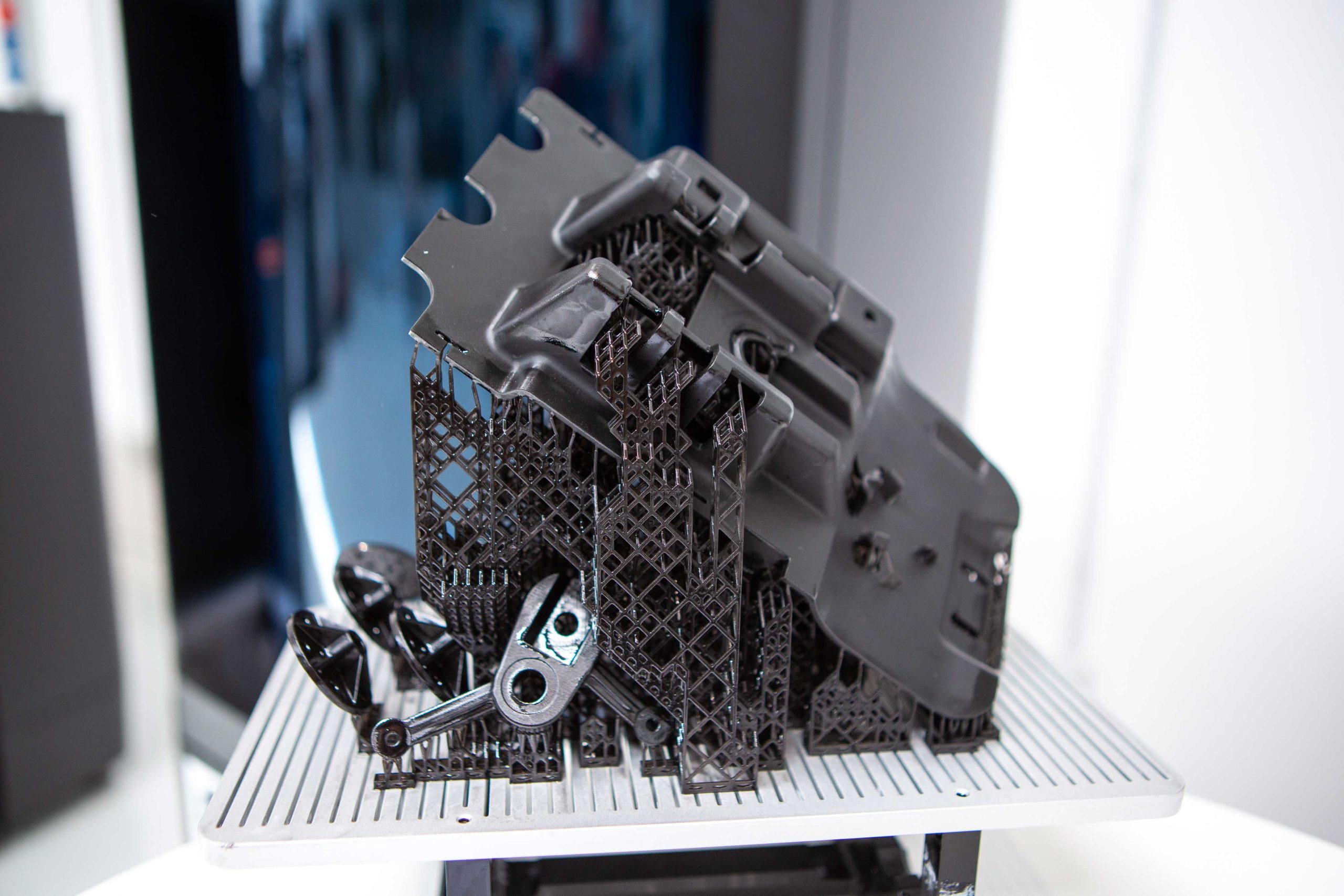

Optimise Printing Process in PreForm

Design your model in standard CAD software and import it into our PreForm print preparation software in STL or OBJ format. Prepare your model in minutes, upload it to the printer and start printing.

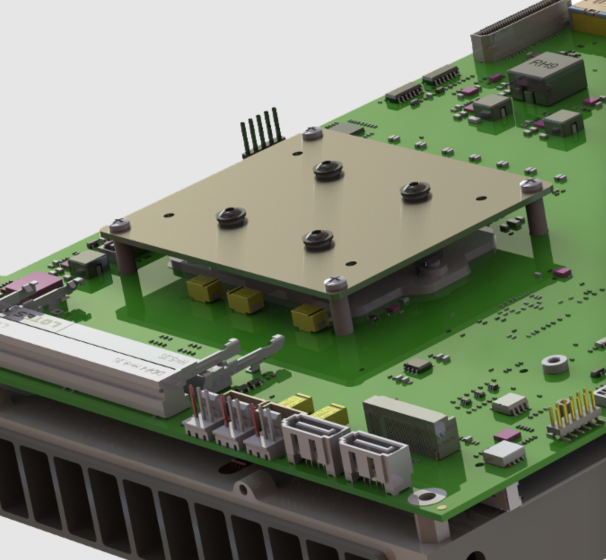

Twice as powerful laser

Two staggered Light Processing Units (LPUs) inside the printer use a compact system of lenses and mirrors to provide accurate and repeatable prints.

Build Platform 2L -NEW

With Quick Release Technology, a patented quick release technology, Build Platform 2L allows parts to be removed from the print platform in seconds, without using any tools. Make your post-processing workflow smoother by removing finished parts quickly and accurately.

Faster printouts

The two LPUs run simultaneously along an optimised print path to efficiently track parts of all sizes.

Uninterrupted Printing

Form 3L constantly monitors print performance allowing you to focus on the creative part of the job: shaping your ideas. Built-in sensors help you maintain ideal printing conditions for continuous output with minimal supervision.

Crisp, clean details

Each high-power density laser is passed througha dimensional filter to ensure a sharp laser dot.

Uniform accuracy

A parabolic mirror ensures that the laser prints perpendicular to the printing plane ensuring uniform print quality across the entire printing platform.

Intuitive and efficient

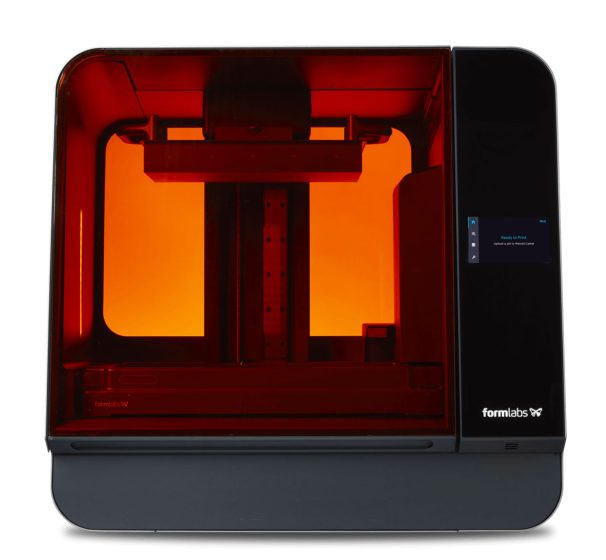

There is no need to hire specialized technicians. The Form 3L offers automatic resin dispensing, simple print preparation software, and a carefully designed interface

Extraordinary part quality

You won't have to sacrifice quality to achieve large prints. Form 3L allows you to create parts with the smooth surface finish and fine details that stereolithographic 3D printing is known for.

Download

Contact us to get more information and request a quote