3D Printing for Mechanics

3D printers for large-scale production and industrial manufacturing

3D printing has increasingly become a decisive resource for the mechanical engineering industry, changing the way small and large companies bring their designs to life, quickly and at a reduced cost.

This technology makes it possible to increase the productivity of all types of companies, maximize the return on investment, and optimize the design process, with reduced costs, manufacturing products that are the perfect combination of strength and lightness.

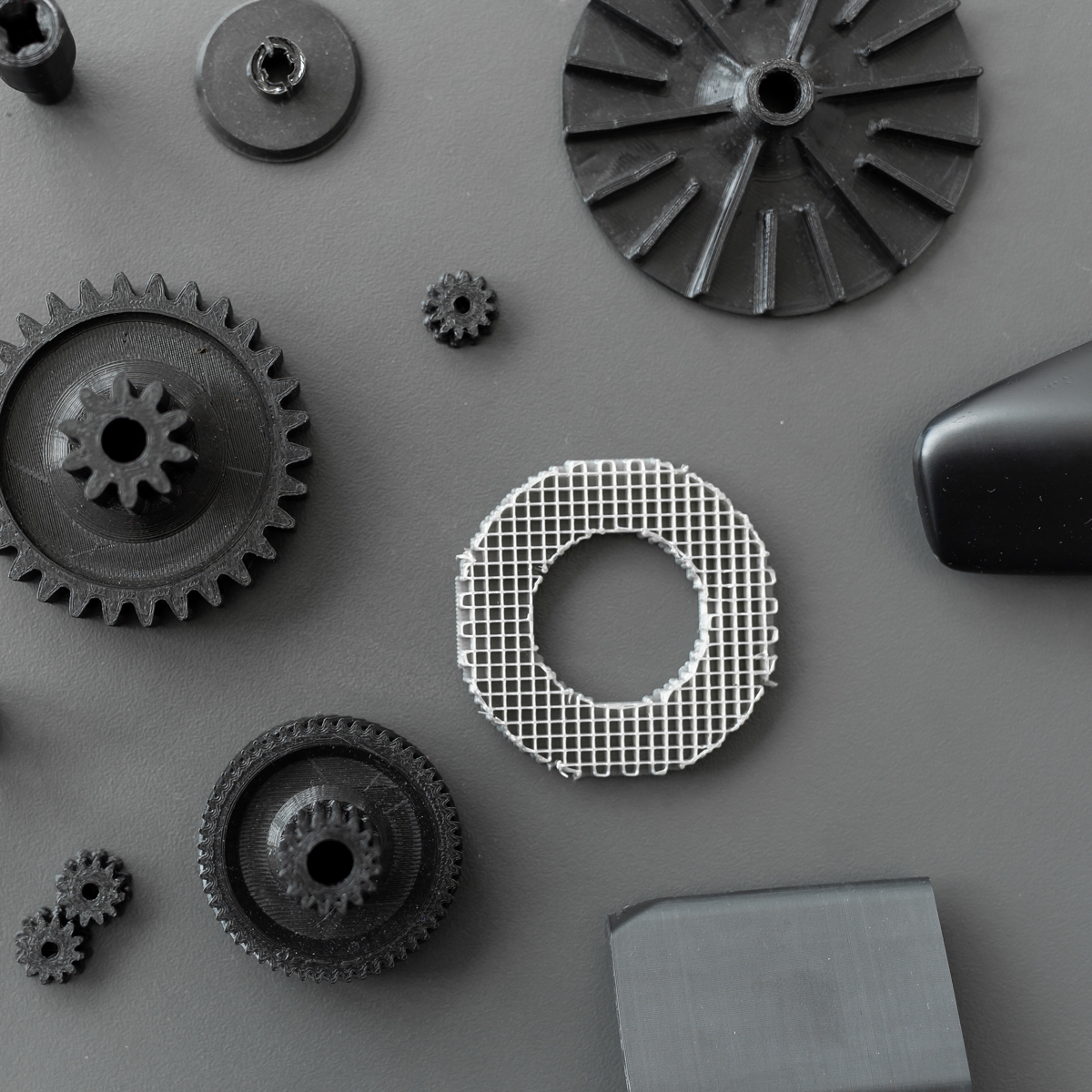

Thanks to the latest solutions it is possible to produce thousands of mechanical parts in a few days, printing both prototypes and finished parts with any level of complexity.

3DZ provides the best solutions on the market from manufacturers such as 3D Systems and Markforged, which make numerous 3D printers for the manufacturing industry that are useful in a variety of sectors and applications, from prototyping to more massive production.

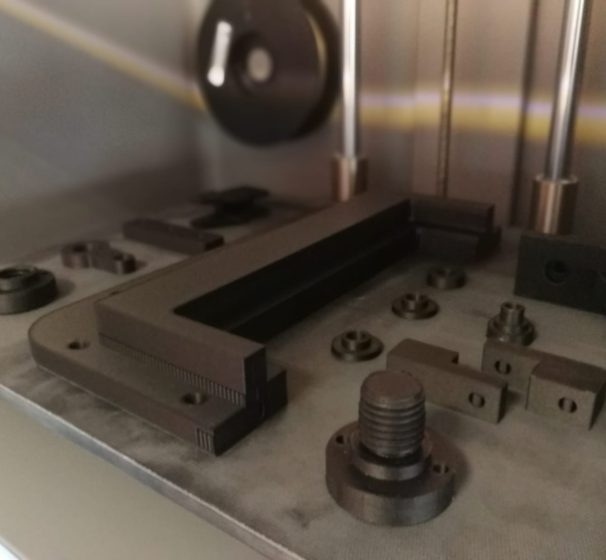

The solutions available are based on many different technologies, including Stereolithography (SLA), Direct Metal Printing (DMP), Fusion Deposition Material (FDM) and Sintering Laser (SLS).

Each individual technology addresses different needs related always to specific applications, such as making a titanium element or a Nylon and carbon fiber fixture.

Challenges

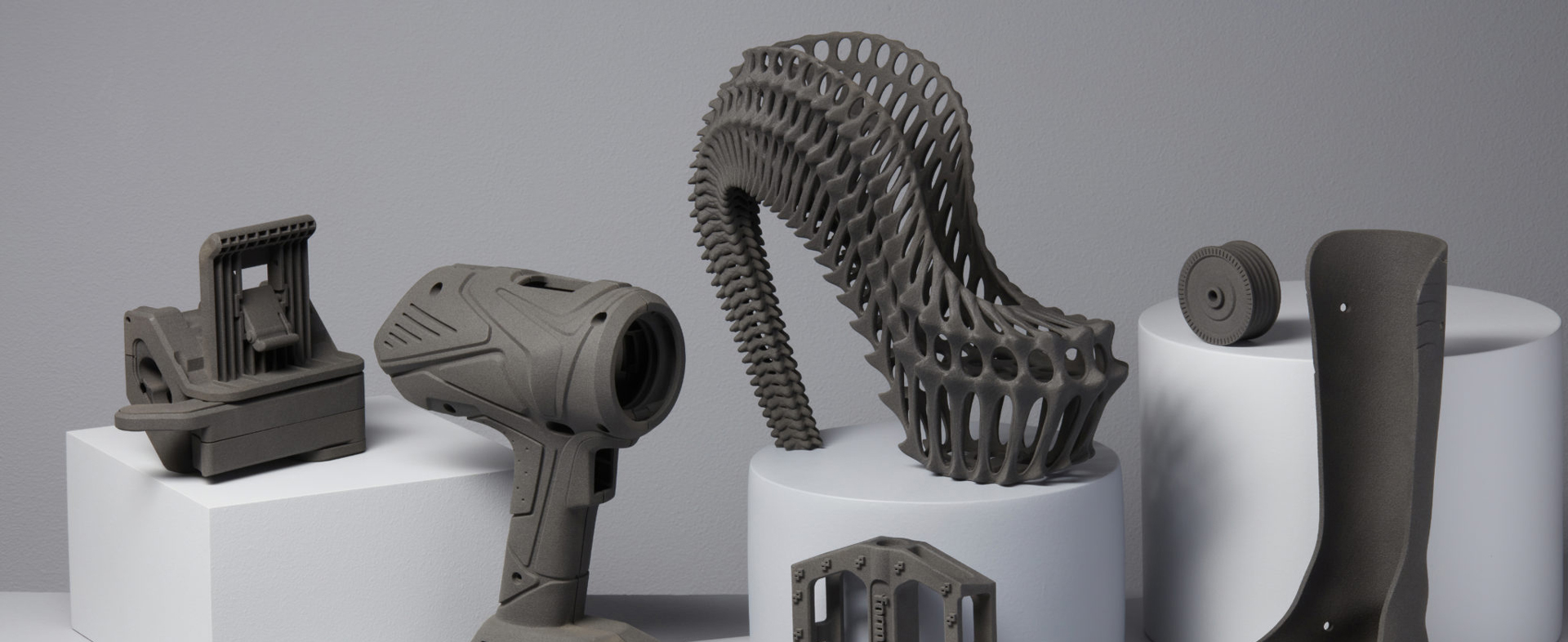

3D printing in the mechanical engineering sector makes it possible to increase the productivity of all kinds of companies, maximize the return on investment, and optimize the design process, with reduced costs, producing products that are the perfect combination of strength and lightness.

Minimize the number of assemblies, welding steps, and parts that compose an object, making it less likely to have weaker points and unclean areas.

Reduction in overall weight, risk of failed points, and assembly time, thus increasing the quality of product performance, which is becoming lighter and stronger.

Creation in shorter and shorter timeframes of multiple molded products, from small batches to large production runs, from prototypes to spare parts, without the need to stock the product.

Reduction of wasted material through an on-demand production approach.

Reduce warehouse space as much as possible, increasingly eliminating the need for stocking up.

Products

Our success stories in the field of Mechanics

Request a consultation

Contact us to get more information and get a personalized consultation

Contact us